Diesel of the Week is presented by

The Engine Builder team was in Memphis, TN last week to film some video content, and being in such close proximity to Choate Engineering Performance in Bolivar, we knew we had to stop by and say hello. The diesel shop won Engine Builder’s and Autolite’s 2022 America’s Best Diesel Engine Shop award, and for good reason. What began in 2013 as a small operation in a 7,500 sq.-ft. space has since evolved to a well-oiled machine pumping out engines from a 155,000 sq.-ft. facility.

The success of the shop today is thanks to founder Cass Choate, who’s refined and expanded it over the years. Choate Engineering Performance is made up of three segments – repair, engine building and part manufacturing.

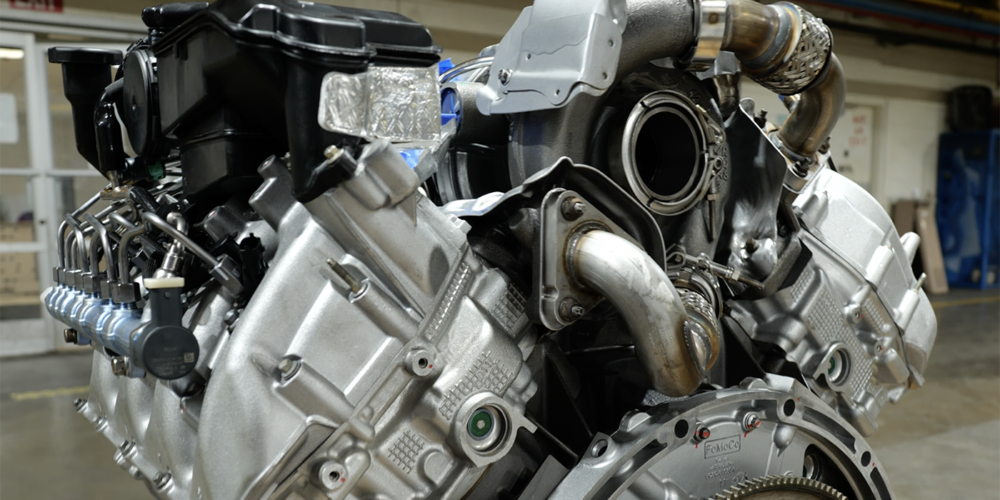

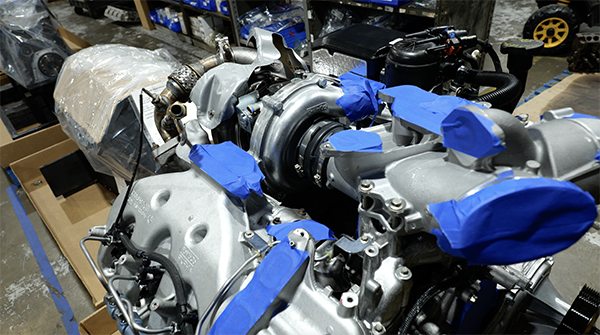

In its early years, the shop worked heavily on the Powerstroke platform, and built up a reputation for that work, despite it only being a portion of what the shop could do. It wasn’t long before the shop also became known for its Cummins and Duramax work as well. However, when we stopped by, Cass wanted to return to his bread and butter and show us a recent Powerstroke build.

“The 6.7L Powerstroke has been around since 2011, and since then they’ve had a lot of time to adapt, change and make revision to this engine,” Choate says. “That being said, one of the big problems they had right from the start was the clearances on this engine. They were really struggling to increase fuel mileage and in doing so, we got mains that were entirely too tight. Moving up the engine, a lot of the problems we saw involved the crank spinning. You’d come in and see 32 pushrods that were all bent.”

This particular Powerstroke build is one of Choate Engineering Performance’s “mild” builds (although they do build higher-horsepower versions for competition too). It makes around 550 horsepower and serves the guy who needs a dependable ride to work, or capable towing vehicle for a camper, boat or trailer of horses, and can also play around on the weekends.

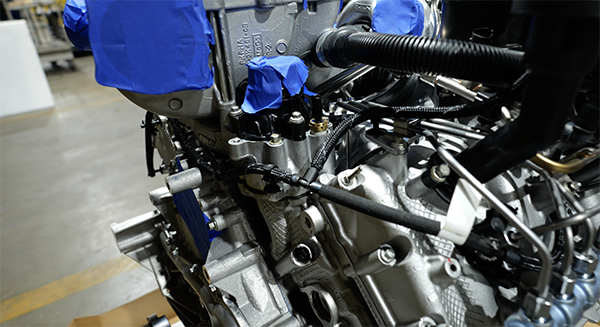

To solve the issues with the 6.7L Powerstroke and produce a result that’s more reliable than Ford’s factory product, Cass and the team worked with manufacturers to come up with a bearing with correct clearances and a much higher tensile strength, tig-welded gears, and much stronger connecting rods.

“Another one of the big things we do is manufacturing, which is on the other side of our shop. Billet main caps are a big plus that support this build. We always obviously do a lot of machine work, so this engine has been honed, balance, and given a surface finish.”

“The next option up we have is our ‘Workhorse’ build. What you’d see there is a different camshaft profile, different connecting rods, and a billet flex plate among other things. That one would be bumped up to around 650-700 horsepower, and then of course we can go up from there.”

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].