Motorsports and car enthusiasts of all types indulge their interests to have fun. Nothing kills fun faster than stuff breaking or not working properly. A common cause of failure is mismatched parts or systems. Improper choices can create weak links or simply not work at all due to incompatibility. At Borowski Race Engines, we have found it very beneficial to help customers avoid these pitfalls on their builds by offering “complete” systems tailored to their needs.

Our expanded involvement improves their outcomes, reduces time requirements and simplifies tech support. Doing it right the first time usually saves a lot of money as well. What is a “complete engine?” For decades, it meant carb to oil pan. Drop it in and it will run. That is no longer the case with modern engine types such as the LS/LT family, which are controlled by an ECU.

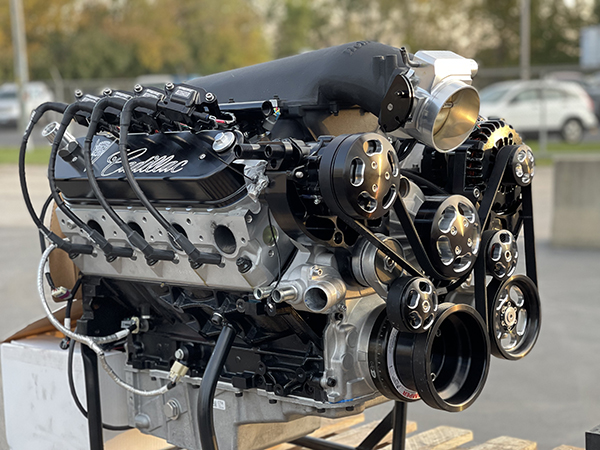

The engines we build are often put into either resto-mods that never had an ECU, or newer vehicles with incompatible ECUs. What about the serpentine system? As will be discussed, there are a lot of issues in serpentine system selection that can be avoided by including it under the definition of “complete engine.” Our complete engines are delivered with a customized serpentine system and engine management system loaded with the tune finalized in its dyno session. We take this concept to the next level by offering “complete systems,” which include the related components of transmission and fuel delivery. Importantly, we stock the parts we use and sell available inventory to retail customers, speed shops and other engine builders. The shops we sell to appreciate not having to do the research on pairing all the system components themselves, as time is money for them.

In today’s world of supply chain disruptions, it is a big benefit to be able to source an entire system from our inventory and not have to wait for that last back-ordered component to arrive. Vehicles waiting for parts are profit-killers for most shops and a major source of dissatisfaction for their customers. The net result is that ordering a complete system from us is good for their business and good for their customers.

Retail customers don’t typically have the knowledge of a professional car builder, so they need more help in making proper choices. Prospective customers usually call with a specific item in mind. We try, however, to expand the conversation to understand what they are trying to accomplish and make sure they’re on the right path. It’s helpful to, “Begin with the end in mind” and “If you don’t know where you are going, any road can take you there.”

Our first few questions are typically, “What’s the vehicle?” “What are you trying to accomplish?” and “What’s the budget?” Racers usually have more specific objectives than the street performance customers. They also typically have an ET or horsepower requirement in mind with other parameters set by their class of competition. This information brings us from the 40,000 ft. level to 10,000 ft. Since our business model relies heavily on building known engine combinations from inventoried parts, the core engine parameters (block, crank, rods) are now largely defined.

Further discussion covers power-adder types, available fuels and desired level of maintenance. We are power-adder agnostic, but in general, we believe in Ockham’s Razor – the simplest solution is usually the best one. Naturally aspirated is therefore our preferred starting point with power adders used as needed. NA builds have fewer components and all else being equal, cost less to purchase and install while also being simpler to operate and maintain. We like to keep mechanical cams and valve lash adjustments away from casual racers and most street performance customers.

Most people define their engine requirements with a single number for peak horsepower. In fact, horsepower is a function of torque and rpm. Therefore, three different types of power adders can produce the same peak horsepower, but with very different torque curves.

The twin screw supercharger delivers high torque at low rpm as can be seen with its relatively flat torque curve. The centrifugal supercharger and turbocharger both had much steeper torque curves (lower horsepower at low rpm). Not surprisingly, the centrifugal supercharger’s torque curve was more linear than the turbo’s as it is driven off the crank. Nitrous oxide is an animal unto itself, as it is far more user defined.

While choice of power adder may be personal preference or competition class defined, it is good to know and understand their differences. They all can work, but one or another may be better suited to a specific task. We are happy to review the options with customers to help them make a more informed choice.

Power-adder engines are particularly sensitive to tuning. Since we have likely built the identical engine before, we have a solid starting point for the tune. This means a better dyno break-in with fewer pulls and a much tighter range of conditions. Getting the engine with our tune already on the ECU is a major advantage for the buyer. Depending on the particulars, the need for further tuning on a hub or chassis dyno is either reduced or eliminated. The engine management systems we typically sell for street are often self-learning and adjust themselves to the car and driver over the first week or so.

Our street performance customers add several other layers to our line of questioning as their wish list includes more aesthetic aspects and practical considerations. Intake manifold choices by racers tend to be made based on performance and cost. Street performance customers are more influenced by appearance and hood clearance. Custom engraved valve covers and engine paint schemes are also very popular with this group. Drive-by-wire and drive-by-cable are considerations that can affect ECU and throttle body choices. Electronic overdrive transmission control capabilities are also part of ECU selection.

The higher horsepower of our street engines and other user specific requirements make the serpentine system a key element of a complete engine. Strength of the bracketry and crank pulley are critical, particularly with belt-driven superchargers. The harmonic balancer choice must be appropriate for the engine’s power. The finishes of the serpentine and engine are often customized.

Today’s resto-mods are rarely bare bones. Stereo systems and air-ride compressors add a lot of electrical power demand on top of what is needed for basic engine management and fuel delivery. Running out of power is a lot worse than running the gas tank empty. Our usual starting point for street alternators is 225 amps and we sell quite a few at 300 amps. Hydraulic brake assist is very popular as it works great. Having the necessary fitments on the power steering pump greatly simplifies installation.

ProCharger recently introduced their D1X integrated serpentine system. Purchasing a fully integrated system from ProCharger eliminated the need for us to come up with such a system ourselves. It is offered in both 8 and 10 rib belt variants. We chose the 10-rib for more traction at the expense of slightly higher price and dimensions. For those not yet ready to boost their ride, the supercharger can be added to the serpentine system at a later date.

Once our D1X system arrived, we paired it with one of our boost-ready 370 cubic inch, hydraulic-roller LS long blocks. The foundation is a seasoned GM 6.0L iron block digitally remastered on our CNCs and paired with a Callies Compstar 8-counterweighted crankshaft. The additional counterweights reduce harmonic vibration and increase crank stiffness by about 25%. While there is a lot more that could be said, we topped the engine with a Holley Lo-Ram intake manifold, which is sandwiched with a 417 Motorsports liquid-to-air intercooler.

Once on our dyno with its Holley Terminator X engine management system, this combination effortlessly made 1,063 horsepower on pump gas. The net result is a complete engine that is as close to being a drop-in as possible.

The bracketry of the D1X integrated serpentine system is compatible with ProCharger’s larger F-1 line of superchargers. We would pair, for example, an F1-X with an aftermarket block and other upgraded parts to better support the higher horsepower. Choices for controlling inlet air temperatures include liquid-to-air intercooling, as mentioned above, as well as air-to-air intercoolers which expand the range of compatible intake manifolds. No intercooling is required if the plan is to run on E85 or methanol. Other changes in the build such as fuel injector sizing would be needed to accommodate alternate fuels. Serpentine system dimensions can be found on ProCharger’s website.

Turbo builds have their own challenges that are often fabrication related. One of our turbo LS engines was delivered with a Holley bracket-less mid-mount serpentine, customized Hooker wrap-around turbo headers and a Holley Hi-Ram with intercooler. These elements were selected to minimize space requirements and thereby allow fitment.

By purchasing a complete package, one can avoid common and potentially expensive pitfalls while achieving a better outcome in less time. After-sale service and support are simplified if the package was purchased complete rather than pieced together by the purchaser. Bottom line, offering complete engine packages is more fun and less grief for both you and your customer. EB