Diesel of the Week is presented by

3.0 Limited Pro Stock engines are high-performance diesel engines used in truck pulling competitions. These engines are designed to produce massive amounts of power and torque, allowing the truck to pull heavy loads over a short distance.

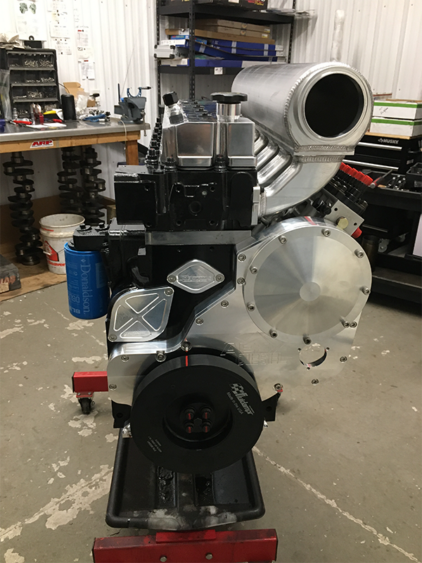

The 3.0 Limited Pro Stock engine is typically based on a standard 6.7L or 5.9L Cummins diesel engine block, although Duramax engines are also used. The engine block is often sleeved with stronger materials and the crankshaft is also usually upgraded for increased strength; other heavily modified components are tacked on to increase performance even further. The 3.0 Limited Pro Stock engine is also equipped with high-performance pistons, heavy-duty connecting rods, and a custom camshaft. These components are designed to withstand the high stresses generated by the engine’s power output.

Dustin Harrison, owner of Apex Diesel Performance, is versed in building engines for this class. His Atlantic, PA shop opened its doors in 2014 and they’ve been completing quality, performance Cummins engine builds ever since. We first spoke with Harrison in late 2019, where he told us all about a Super Stock 6.7L Cummins he was building at the time.

The Limited Pro Stock engine he just finished for competitor Trent Krulik will have less horsepower on hand than that Super Stock Cummins build, but that doesn’t make it any less impressive.

“They’re about half the power of a Super Stock, but it’s an interesting class since there’s so many restrictions on how you make power,” Harrison says. “They’re air-limited, so they’re restricted to a 3-inch smooth bore inlet on the turbo, and you can’t have water injection. So, all we have is a 76mm turbo on there and it’s making close to 1,600 horsepower, which is quite a bit for a small, single-turbo application.”

The engine’s airflow is often an important aspect of Limited Pro Stock building, which is improved with the use of a custom cylinder head and intake manifold. The factory cylinder head Harrison used was ported and polished to increase airflow, while the Wehrli 24v billet runner intake manifold was designed to distribute air evenly to each cylinder.

One of the critical components of a 3.0 Limited Pro Stock engine is the fuel system. These engines typically use a static mechanical fuel injection system that is capable of providing high-pressure fuel at high volumes. The fuel injection system is tuned to deliver the optimal air-fuel mixture for maximum power output. Harrison employs a rather large 16mm Scheid Diesel P7100 injection pump. The 16mm plunger pumps can produce more than 1,500cc of fuel and spin more than 7,000 rpm in certain applications.

Apex Diesel Performance manufacturers and sells its owns parts too, many of which are featured in this build.

“It’s got one of our 14mm girdles, a set of our 1″-longer deck plate connecting rods, and a custom-spec flat tappet camshaft that we have LSM Engineering grind for us,” Harrison says. “It also has custom-spec Diamond pistons, which we use for most of our builds.

“We use all ARP fasteners, 14mm on the top, bottom, main studs, head studs, etc. We use half-inch L19 rod bolts in our rods and since we upgraded to a half-inch, we’ve had absolutely zero rod issues. We run Total Seal rings too and we haven’t had any issues in that regard either.”

Overall, the 3.0 Limited Pro Stock Cummins is a highly specialized diesel engine that is purpose-built for truck pulling competition. The good part about the class, Harrison says, is that once you have a built-up truck, chassis and engine, you have a reliable competition machine that will last for 2-3 years before needing a refresh.

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].