Diesel of the Week is presented by

It’s always a good feeling to finish up your first build, and in this industry, there’s no shame in showing off what you’ve created. In fact, some of our favorite guys to talk to are the ones who just got started in the industry, or ones that have been in it for years and just got around to their first major build. It’s awesome to see the progression from first timer to professional, and oftentimes those first timers blow us away with what they’ve come up with.

Josh Kaye from West Bend, WI recently reached out to us regarding an engine he put together for his 2006 Chevy Silverado 2500. He owns a business called Kaye’s Trucks and Parts where he sells repair parts and equipment for Chevy and GMC trucks, alongside a small dealership he opened just a few years back.

Performance work isn’t really a part of the operation at the moment, but that could change in the future. For now, Kaye is content with his recent build.

“This truck was originally a gasser I shipped up from Texas in 2017,” Josh Kaye says. “I did some minor frame work, put an Escalade 6.0L motor in it and did a cam, lifters, valves, and all that. The 9-inch lift kit happened in 2020 and then in 2021 the engine blew up. That’s where the diesel project started.”

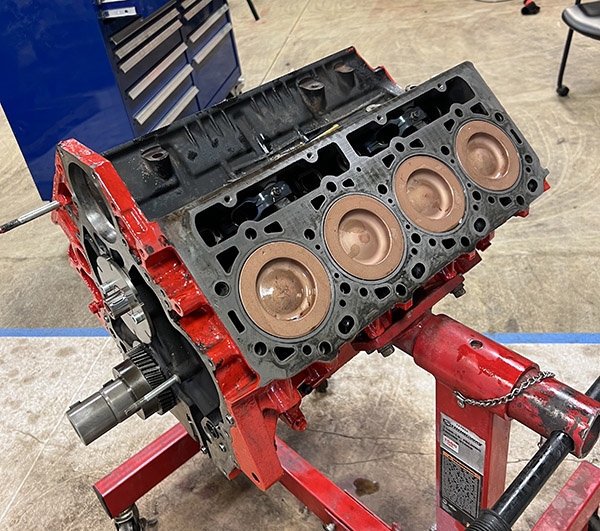

The LBZ Duramax came from a donor truck Kaye had purchased at an auction. After bringing it home, he tore everything apart and started building it back from the ground up. To make sure the block was clean and ready for a rebuild, it was first blasted and then surfaced.

After doing some research on rotating assemblies for sub-1,000 horsepower builds, Kaye decided to stick with the factory crank, which he had balanced, keyed and polished by No Limit Manufacturing. The connecting rods also stayed stock.

“I went with Mahle LB7 de-lipped pistons with a thermal coating to withstand the high heat,” Kaye says. “I got a Mahle grade C head gasket kit on it, and I went with Exotic Brand head studs. They were a cheaper alternative to ARP, and they’ve been holding up really well so far. The H-series cam bearings, main rods and thrust washers also came from Mahle.”

Pretty much everything else bolt-wise on the engine is from ARP, including crank bolts, rods bolts, and main bolts.

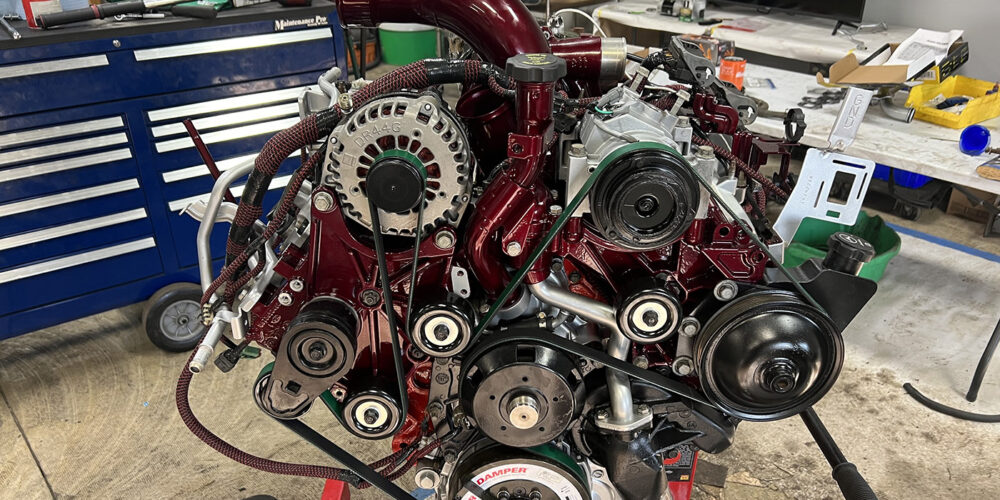

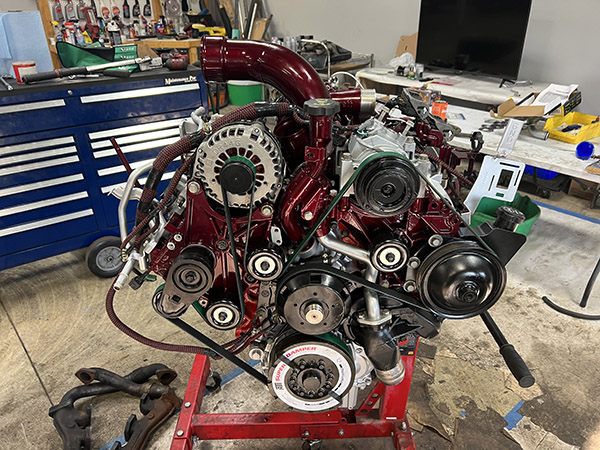

LBZs are known to have a prolific crankshaft issue where they snap due to the firing order. To fix this, Josh installed an alternate-firing order cam that changes the firing order and puts less stress on the front snout of the crank. Mounted to the crank is a SoCal billet flexplate. The factory heads were ported, cleaned, decked, and pressure tested before being put back in the engine.

“The factory dampers on the trucks are fine, but overtime they tend to stress out a bit, so I went with an ATI Super Damper and that worked really well with doing the keyway on the crank,” he says.

“There’s PPE stainless up pipes and PPE race manifolds on it, we a have a full WC Fab high-flow intake kit, there’s a 12mm CP3 from Dan’s Diesel Performance, an AirDog 24G 165 lift pump, and for injectors we have 100% overs from WC Fab. Then, on air, we have a 72mm Stage 2 10-blade turbo from Dan’s as well.

“I think that’s the one thing limiting it at the moment,” Kaye continues. “Since it’s a 72mm, it’s kind of pushing the size of a stock housing. I was told these are used mainly for pulling or in drag trucks and I’m just driving this thing on the street, so eventually I’ll probably end up changing it up and going with an S400 setup or some sort of compound configuration.”

Altogether, Josh’s LBZ Duramax makes right around 850 horsepower, which is just right for what he’s using the truck for. Josh mentioned that he might look into getting into drag racing in the future, so we’ll be sure to keep up to date with any of his future builds!

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].