Welding Rod Storage

Regardless of the material, in time, humidity takes its toll. As such, many welding rods end up being trashed. Especially susceptible are aluminum, magnesium and chromoly. I keep my rods in hermetically sealed homemade tubes of plastic plumbing pieces to keep humidity out.

Archie Frangoudis

Archie’s Racing Service

Merrimack, NH

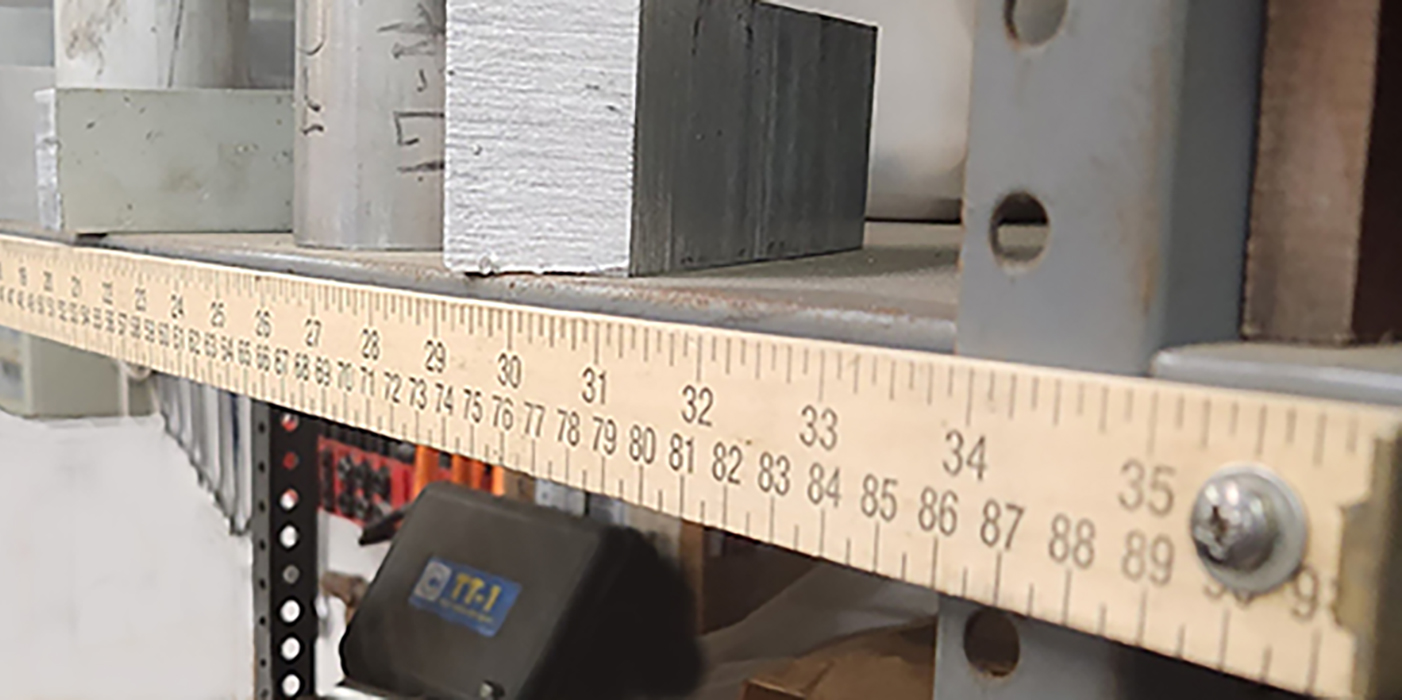

Twice the Scale

I adapted this rod weighing setup after seeing my friend doing something very similar. If the point of contact with the scale is not the dead center of the bore on each end of the rod, you will not get accurate readings. I turned some mandrels on the lathe that slip fit in the rod bores. Then, I made some axles out of stainless, so they don’t rust, and weight-matched them so it doesn’t matter if they get mixed up. This setup is repeatable to within a few tenths of a gram every time.

Jake Sampson

AMS Performance

West Chicago, IL

Guide Saver

To avoid cracking the guide when ball broaching liners, I made collars that slip fit over the guide. I’ve used large valve guides, aluminum and steel round stock to make them. The time invested is quickly offset by not needing to replace cracked guides.

Randy Torvinen

Torvinen’s Machine Shop

Menahga, MN

That Smell

Many shops are now using CNC machining centers with coolant tanks/sumps. With time, the coolant will grow a foul-smelling bacterium, especially during the warmer summer months. The cure for foul-smelling is coolant deodorizing tablets, available from many industrial supply companies. Made specifically for use in machinery coolant tanks, the recommended dosage is one tablet per 25 gallons every two weeks.

One tablet is approx. 3.5 oz. The material safety sata sheet states the ingredients as sodium tetraborate decahydrate and water. A tube of only 15 tablets (approx. 52 oz.) costs about $45 plus shipping, or about $3 per dose. Borax is a common name for sodium tetraborate decahydrate (also known as sodium tetraborate, sodium borate, or sodium borate decahydrate). It’s used as a laundry cleaner, in toothpaste, sunscreen, paint, and as a welding/brazing flux. A 65-oz. box (approx. 18 tablets) of powdered borax found in the laundry/cleaning supplies aisle is only about $5 – or less than 30¢ per dose. Three heaping tablespoons of powder is approx. one tablet.

Tom Nichols

Automotive Machine & Supply, Inc

Joshua, TX

Added Hone Tank Filtration

Lay used air filter rolls under your engine block, or other parts being honed, to collect as much grit as possible. It saves you time and money by extending the life of the oil filter on your machine. We triple up the layers directly under our honing area and change those out monthly. This keeps the machine clean looking and also makes it easy to find items dropped. Industrial buildings generally use 30”-36” wide fiberglass filter material for their HVAC system, so there are plenty of used rolls out there.

Segars Engine Building

Mike Segar

Bloomington, MN

GRINDING THE RAILS

When grinding the thin, steel, oil rails on a ring grinder, lay it on a used, cast-iron, second ring and grind them both together. This reduces the chance of the rail biting or fluttering and damaging it. If you’re careful, you can grind the two for that cylinder together to save time on a powered grinder. On my ABS grinder, I’ll also grind three-to-four oil rails at a time, which stabilizes them. The top oil rail should have a gap the same as the second ring. This allows any pressure spikes to evacuate to the oil returns in the third ring groove. Constant, controlled blow-by makes for a stable ring pack, more horsepower from better sealing and longer life.

Ron Flood

Cedar Machine

North Branch, MN