Can Used Race Parts See New Life?

Eatmon Racing Engines Finds Veterans to be Valuable In 1950, the Mexican government sponsored a race to inform the world that Mexico had a new system of roads known as the Pan-American Highway, which stretched across the country from north to south for commerce and tourism. That race was the original Pan-Am. Today, known as

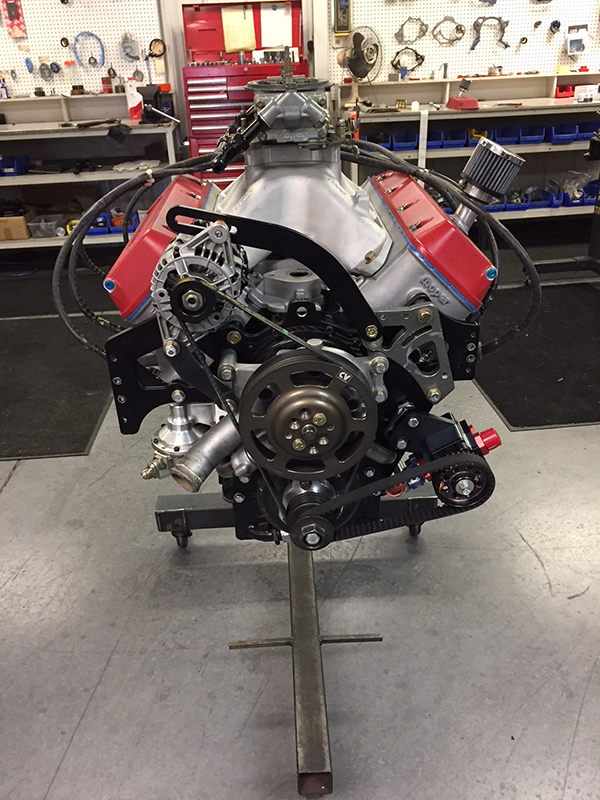

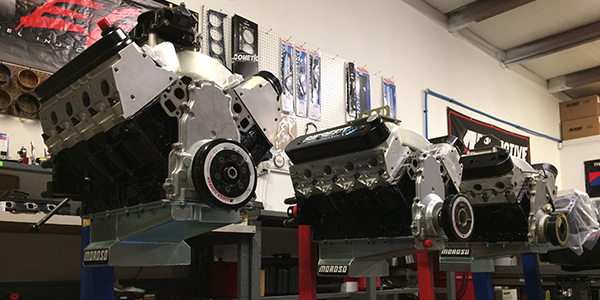

Building Stroker LS Engines

What is so great about these LS engines? First, the LS engine has multiple design features that help it achieve near-big-block levels of horsepower. With a 15-degree valve angle, intake ports that flow 300 cfm and a 55mm camshaft diameter, one can see what the engineers at GM were after when designing these engines – efficiency and performance.

Updating the Ford 8.8 Differential

Conventional wisdom says that if you are going to upgrade any kind of performance engine, your customer will likely need to upgrade other components. Brakes, suspension, transmission – all components that can be impacted by dramatic increases in power. The rear end is no different. In many cases if you’re adding big power (especially for

Vibrant V-Twins

Capitol Speed Shop keeps Harley-Davidson motorcycles running two cylinders at a time At just 23 years old, Marty Smestad became one of the youngest people ever to reach Harley-Davidson’s Master Technician level. He attended Motorcycle Mechanics Institute in Phoenix straight out of high school to focus on Harley and Honda engine work and that background allowed

CNC Machining Equipment

What’s Keeping You From Making the Plunge? I’ve discovered when I talk with Engine Builder readers about CNC equipment the conversation often falls one of two ways: it’s either the best idea in the history of the industry or it’s just too expensive, too complex or just too different. In conversations with equipment suppliers, on

The Market For Commercial/Industrial Diesel is Thriving

Off-highway diesel engines are designed to perform in many different applications across multiple industries. These engines must be able to perform consistently and reliably in extreme conditions where there’s dust, vibration, high altitudes and generally harsh weather conditions. Such engines can be found in excavators, cranes, backhoes, forklifts and others that perform a particular job.

Building Buicks

Under the Hood with Buick Specialist Keith Diabo of Gran Sport Autobody Back in 1970, Keith Diabo’s father came home with a new Buick Riviera GS and sparked what would be Keith’s calling in life – restoring classic muscle cars and engines. Not to be outdone by his dad, it wasn’t long before Keith got

Little Victories – Big Bucks from Small Engines

Finding Performance Potential in 4 and 6 Cylinder Engines Let’s get something on the table right now – I’m a V8 guy. As you’ve read elsewhere in this issue, I tend to also chant the mantra, “There’s no replacement for displacement.” Bigger just seems better and badder. Perhaps you’re like me. But let’s take a

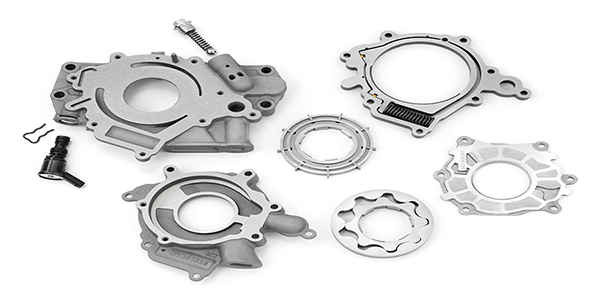

Oil Pumps – Pump Up The Volume to keep Engine in Tune

The Right Oil Pumps and Systems Keep Your Engines In Harmony This month we’re going to take a look at the component that can be considered the heart of your engine, the oil pump. Whether it’s a wet sump, dry sump, crank-driven, shaft-driven, etc. it is responsible for supplying the required oil that no engine

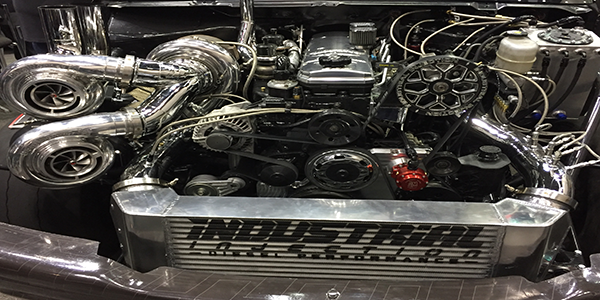

Power Up Those Engines

Selecting the Correct Power Adder for Your Customer There’s no replacement for displacement,” goes the adage. However, this may no longer true considering the kind of horsepower being pumped out of today’s boosted engines. Whether you’re building engines for stock, performance or a diesel application, chances are you’ll be working with an engine that is

Engine Math for Engine Builders

Engine building is a numbers game. Whether you like math or not, you often have to use it when figuring things like engine displacement, airflow, compression ratios and valve lift. Knowing how to calculate these values and how to use the numbers to match pistons, cylinder heads, cams, carburetors and valve train components can help

Cryogenics is Real and It Works – You Just Can’t See It

Cryogenics is a process in which material such as steel and aluminum are exposed to severe cold, down to -320 degrees F to make them more durable and stabilize the metal or aluminum. The closer you get to absolute zero (-459.67 F) the better, but you better not cross that line of -460 F.