Exhaust(ing) Your Options

Here in the pages of Engine Builder magazine we have countless articles about choosing the right set of pistons, putting in the perfect crankshaft, selecting the best connecting rods and the list goes on and on for identifying what parts and products go into your engines. However, there is one item we seldom cover –

High-Tech Tightening – Fasteners take their rightful place of importance

When you build your engines, you put measured thought into every component you use. From the intake system to the exhaust manifold, everything has its place and nothing is installed without careful consideration. But what about the fasteners? Some of the most critical components are held together with relatively low-cost fasteners including screws, nuts and

You Better Think – How to Find Your Niche in a Competitive Market

It was Aretha Franklin who said, ‘You better think…’ many years ago, and while she wasn’t speaking about engine building, the statement still applies to the engine builder’s business. Too often in this industry, and in any business for that matter, the status quo or how things have always been done is the standard. In

Shaking the Rust Off – Preventing and Getting Rid of Rust on Engine Parts

It’s said that water and oil don’t mix. Turns out moisture, air and metal don’t get along real well either. There are many things that can damage engine parts, causing them not to function correctly or be as dependable as they could be, and one of those variables not necessarily top of mind is rust.

Sourcing CNC Solutions – Making the decision for CNC may be scary, profitable

CNC machining equipment can be a double-edged sword to many engine builders that promises flexibility and profitability, yet often requires a significant upfront investment. As with any piece of equipment, there’s no “one size fits all” solution, and three top engine builders explain how they overcame the fear of financing and failure to find success

Avoiding Workplace Accidents

You’re probably not going to cry over a little spilled paint, but will you or someone else in the shop literally take the fall for a co-worker’s carelessness? The list of situations that can cause injuries is long: spilled paint, oil and grease; polished floors; loose matting and uneven walking surfaces; cluttered walkways and large

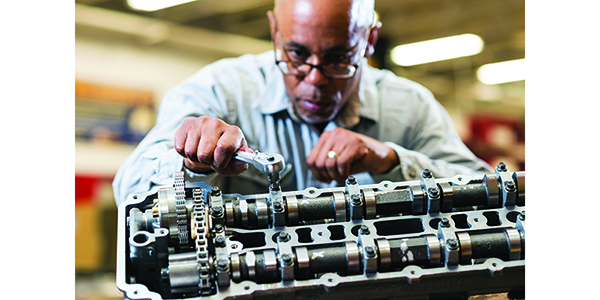

Cylinder Head Design & Selection

Choosing the “right” cylinder heads for an engine build can make all the difference in an engine that delivers and one that falls short of its potential. Horsepower, torque and throttle response all depend on how well the cylinder heads, camshaft and induction system work together. Choose the right combination and you’ll build a winner.

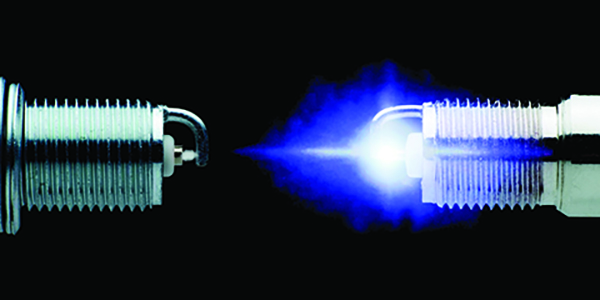

Racing Spark Plugs

Choosing a set of racing spark plugs for a particular application is not as easy as it sounds because the plugs have to be closely matched to the application. Stock plugs are fine for stock applications and ordinary driving conditions. But when an engine is modified to make more power and is run under racing

Crank Grinding – The Myth of the .010”/.010” Crankshaft

Regrinding the crankshaft is an important part of the engine rebuilding process. It was almost an art in the ‘40s, but it’s pretty routine now. However, there are still plenty of myths and misunderstandings that are left over from the past that we still have to deal with today. One of the most common myths

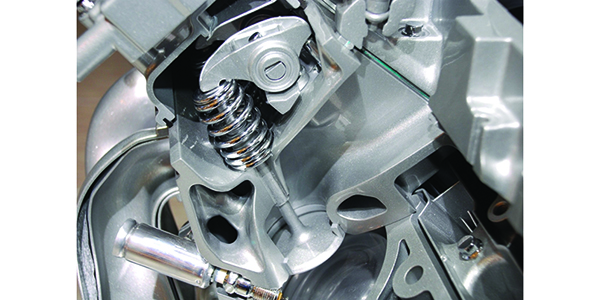

REBUILDING THE 5.7L HEMI

Back in the early ’90s, when Chrysler realized that it would need a new truck motor to replace its 318/360 Magnum engines to meet the coming emissions standards, the company considered two pushrod engines along with one SOHC design and concluded that a pushrod motor with a pair of Hemi heads that really breathed would

Reusing, Reclaiming, Remanufacturing – Whatever you call it, it’s how the industry recycles parts and components

No matter what kind of engine builder or remanufacturer you may be or what applications you build for, at some point in time you’re going to run into a situation where a used engine part or component will come in handy. You’ll reuse, reclaim or remanufacture it for your specific job. Whatever the reason may

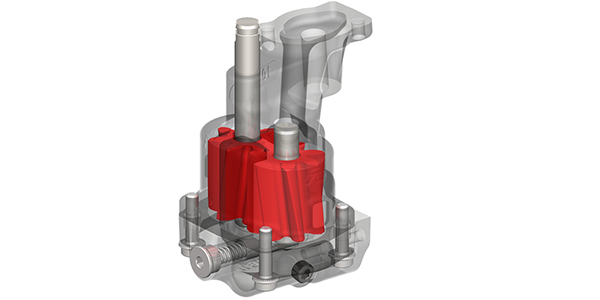

Wet & Dry Sump Oiling Systems – Choosing the Right System for the Right Job

If you are building a customer’s “dream engine” what type of oiling system should you use? The answer to that question will depend on the application (street, drag, circle track, road race, off-road or marine), engine RPM and how much your customer is willing to invest in a lubrication system. Your choices may also be