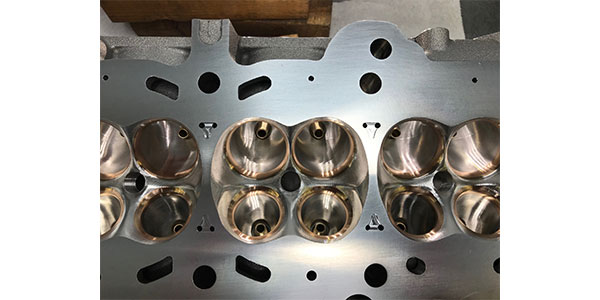

Valve Seats & Guides

Performing valve jobs is one of the most crucial areas of the engine building business. According to our most recent Machine Shop Market Profile, cylinder heads for gas engines account for nearly 16 percent of an engine builder’s production time – and it’s easy to see why.

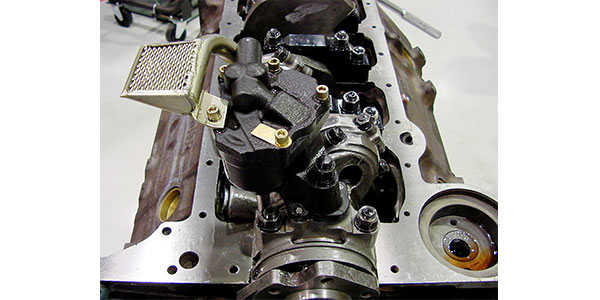

Pumps, Pans & Screens

A stock pump may be just fine for some mild performance, and it may even produce enough pressure for a wilder application, but the limitations are mostly from the housings themselves, which can vibrate and crack at high rpm or under heavy loads.

Harmonic Balancers and Dampers

Although harmonic balancers are not musical instruments, they do control resonance inside the engine, which is music in some circles. There are three types of engine vibration that engine builders try to minimize. And each type of vibration has a different way of controlling it.

Engine Bearing Materials and Selection

One thing every engine builder and even non-engine builder types know is that metal on metal contact is not good. It’s so bad that engine builders will go to great lengths to prevent it from happening. Bearing manufacturers and coating companies also work hard to make sure that their products can withstand extreme abuse without destroying expensive components.

Ultrasonic Cleaning

From cleaning to machining, engine builders are leaving the hands-on approach behind in favor of more automated methods that are also more friendly to the environment. If you’re looking for a system that works as good as some of your methods, ultrasonic cleaning might be a good choice for your shop.

Gaskets and Engine Sealing

What a difference a century makes. Engine sealing technology has come a long way from the days when motors were expected to leak and drip past the gasket and onto the ground or vent out into the atmosphere. In the early 20th century, when most people were switching from horses to cars, other, more natural

Micrometer Madness

I was told a few times that “tenths are for camping” when I was “chasing tenths” in my early machining career.

Pistons & Rings Update

While piston materials and designs have evolved over the years to compensate for higher pressures and heat expansion, selecting a piston that is optimized for combustion chamber conditions can be challenging because there are so many variables to consider.

How and Why Engine Builders Buy Engine Brands

The parts you put into your engines and keep on your shelves for resale are far more than just generic automotive components. You need them to be what you need, where you need, when you need. They’re not just plastic and metal inanimate objects – they’re your reputation. Maintaining that reputation for excellence means you

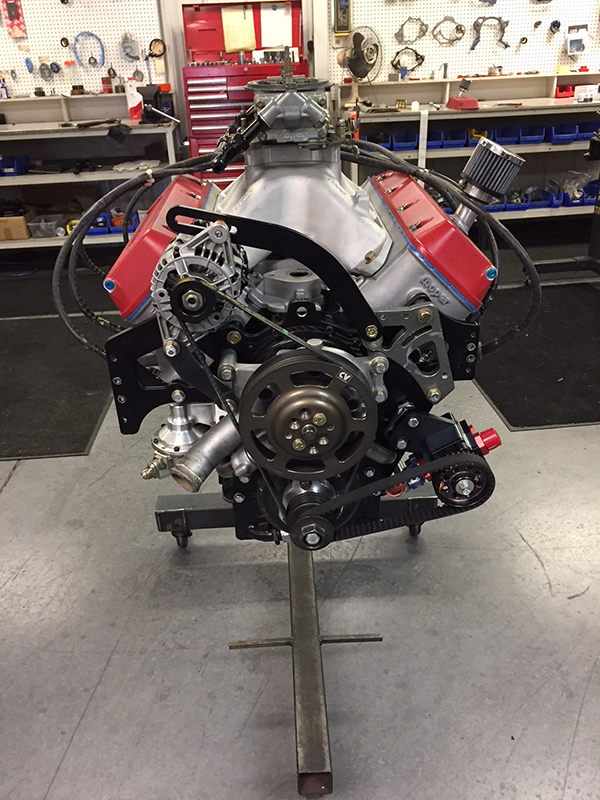

The Heartbeat of Performance

Wet or Dry Sump? The Answer is Science, Not Art You may have heard the analogy that the oil pump is the heart of the engine – as the heart pumps blood to keep us alive, the oil pump moves oil throughout the engine. A failure of either “heart” to pump its fluid properly will

Can Used Race Parts See New Life?

Eatmon Racing Engines Finds Veterans to be Valuable In 1950, the Mexican government sponsored a race to inform the world that Mexico had a new system of roads known as the Pan-American Highway, which stretched across the country from north to south for commerce and tourism. That race was the original Pan-Am. Today, known as

Updating the Ford 8.8 Differential

Conventional wisdom says that if you are going to upgrade any kind of performance engine, your customer will likely need to upgrade other components. Brakes, suspension, transmission – all components that can be impacted by dramatic increases in power. The rear end is no different. In many cases if you’re adding big power (especially for