Sourcing Engine Blocks

Production engine builders today want engine cores that match a very specific vehicle application. In many cases, they also want the tinware that goes with the engine because the oil pan, valve covers and timing cover are also year, make and model specific. That has changed the way core suppliers have to inventory their stock.

Shop Solutions September 2015

Several types of Honda heads have a rocker panel with a set of three rockers together. These rockers have pins that can easily fall out and be lost once the rocker panel is removed from the cylinder head. Before removing the panel, use a small wire to hold the three rockers together.

Toyota Looks to Overhaul its Engines

After ignoring the internal combustion engine in favor of its hybrid car models, Toyota Motor Corp. is preparing a powertrain makeover. The automaker is designing common parts to spread costs across large numbers of engines. This will allow it to economically customize engines for specific vehicles with fuel injection, turbocharging and more.

Chrysler’s Pentastar V6 Gets Major Revisions

Chrysler’s 3.6-liter Pentastar V6 will basically be a new engine when it gets dropped into the 2016 Jeep Grand Cherokee, its first application in the FCA lineup.

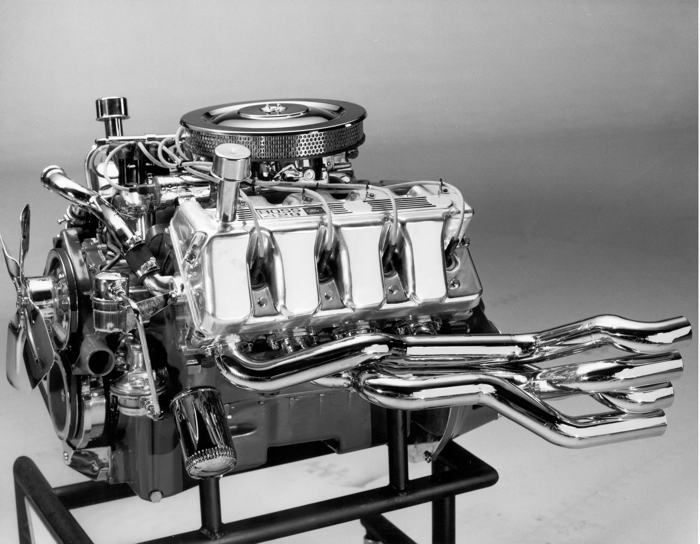

Ford Boss 429 Versus Today’s FR-9

NASCAR’s longtime Labor Day event, the Southern 500, is back home at Darlington (SC) Raceway this year, complete with throwback ‘70s and ‘80s paint jobs to celebrate its rich history. The entire race weekend has become the retro event of the year for NASCAR and Ford Performance talked about race engines with none other than Robert Yates.

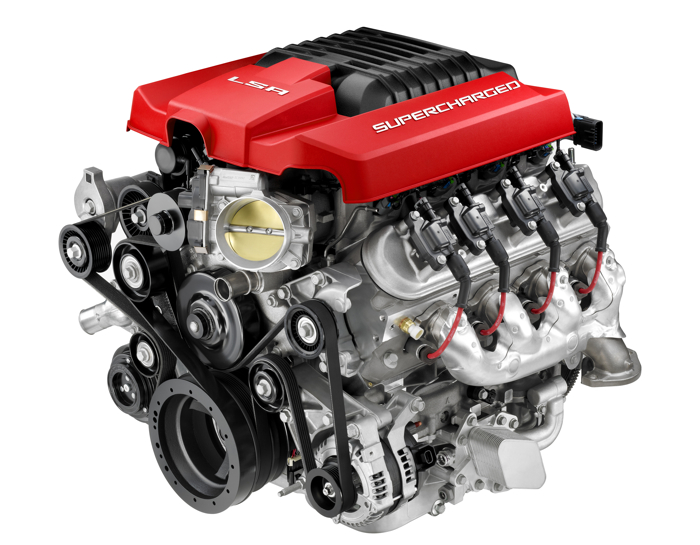

Chevy LS Family of Engines

This new engine family had the same bore spacing as the original small block, but that’s the only thing that stayed the same. The Gen III engine was smaller and lighter, it made more horsepower and torque per cubic inch, created fewer emissions and got better fuel mileage than the Chevy 350 it replaced. It was designed to be built in multiple displacements from day one so it could be used in a wide variety of cars and trucks later on.

Bischoff Racing Engines

Bischoff’s is the largest engine-building facility we have visited. Bischoff started the organization two decades ago with the main emphasis at the time on rebuilding stock engines. Over the years, the attention to performance kept increasing.

Carburetor and EFI Conversions

Carburetors have long served the performance aftermarket and racing industry well. Although they disappeared from new vehicles back in the late 1980s to meet emission requirements, it was only a couple of years ago that NASCAR finally abandoned carburetors in favor of fuel injection.

The Complexities of Modern Timing

Let’s face it: timing used to be relatively easy. These days, however, as with most every other engine component, the technology and innovation that leads to more fuel efficiency and performance also means increased complexity with timing components.

Motor Oil Issues

One of the challenges of building engines for a living is making sure that every engine you build has good oil pressure and suffers no lubrication-related issues once it goes out the door. Good oil pressure requires main and rod bearing clearances that are within your target specs for the application, a good oil pump and the “right” motor oil.

Riding Into a New Engine Market

It’s no secret that there are engine-building opportunities that lie outside of the automotive industry. One such example is with motorcycle and powersports engines. This is a well-established market with numerous OEMs and styles of vehicles with many similarities to the automotive side, yet not many shops choose to explore this market. But if opportunity knocks and you answer the call, you could very well come out on top.

Shop Solutions August 2015

I found myself without a welder to use to remove a check ball staked into the end of an oil passage of a crankshaft. So I applied a different technique to remove it to clean the crank.