Engine Builder Shop Solutions – January 2014

Replacement Head I.D. for Ford 6.0L Diesel Identifying a Ford 6.0L head by dowel size alone does not necessarily get you the correct replacement cylinder head. Ford/International have two casting numbers for their 6.0L head, the early 1843080C1 through C4 heads which all have 18mm dowel holes and use an 8mm mounting bolt for the rocker

December Issue Shop Solutions for Engine Builders

Piston Ring Gapping Tip Some of you may know this ring end gapping tip, but I have never seen it anywhere. Not even in ring package instructions. This has to do with checking the flimsy oil rail gaps. Most conventional size bores are not much of a problem. The rails on those sizes usually have a lot

November Issue Engine Builder Shop Solutions

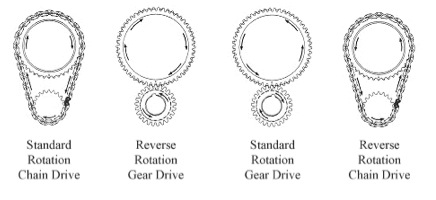

Jeep 3.8L Oil Pressure Problem Many late model 3.8L Jeep engines are losing oil pressure at the oil pump due to failure of the bypass valve. This results in destruction of not only the crankshaft, but the connecting rods. To fix the problem, you need to find the bypass valve inside the plastic timing cover.

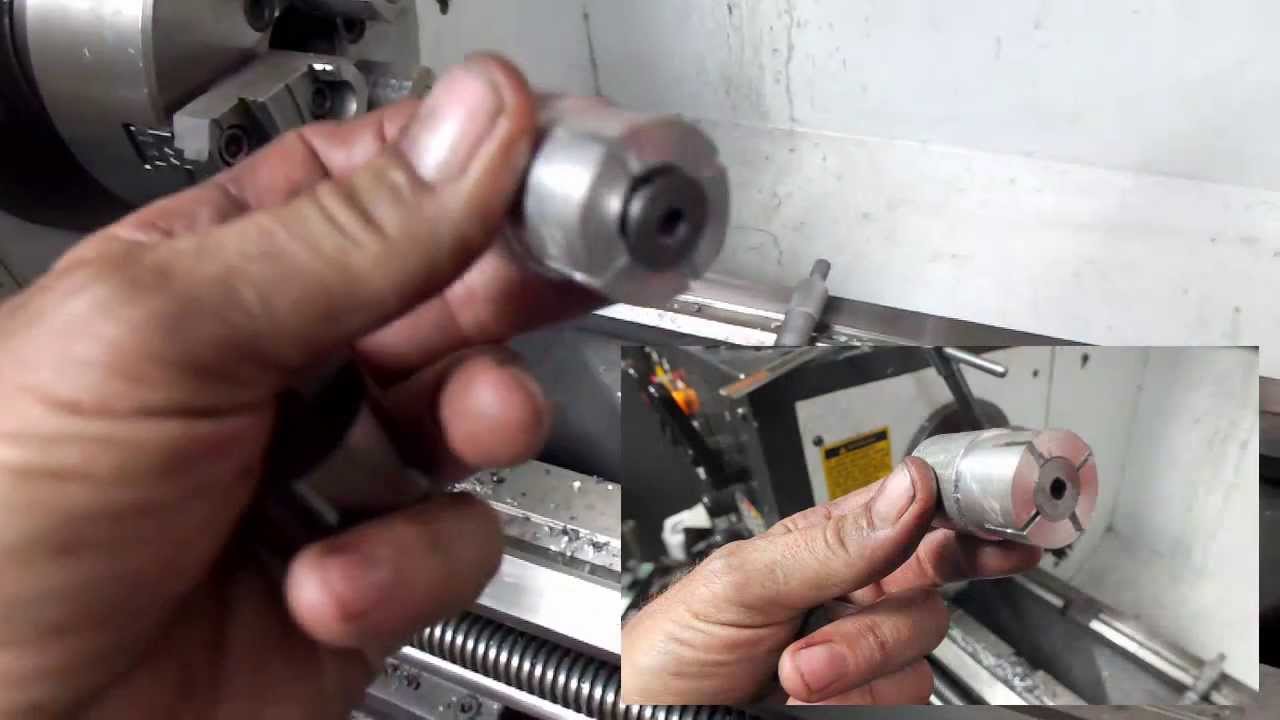

Toyota Oversize Valve Lifter Modification

A Video from John Edwards of Cost Mesa R&D Automotive Machine Shop, Costa Mesa, CA that shows How to Resize OHC Oversize Lifters According to Edwards, occasionally, you will need to buy lifters to make valve adjustments because the one piece tappet is of a specific height and must be changed. This is the case

Shop Solutions: October 2013 Issue

Balloons Belong at Birthday Parties Not in Transmissions I rebuilt a 454 GM engine that went into a motorhome application. It ran well, and no problems immediately appeared. But later on, it was towed in with a main bearing failure in the thrust area. I gave the customer another engine, and a month later it

Engine Longevity: Jaguar’s XK Inline Six-Cylinder

The Jaguar XK inline six-cylinder engine had one of the longest production runs of any engine. Years Produced: 1949-1992 Displacement: 2.5-4.2 Liters Visually, the most recognizable aspects of the XK engine are the dual cam covers atop the engine. The cylinder head’s design was dictated by the desire to make room for two generously sized

Engine Builder Shop Solutions: September 2013

Authors of Shop Solutions published in each issue of Engine Builder Magazine are awarded a prepaid $100 Visa gift card. Shop Solutions may also be submitted to [email protected]. Cylinder Sleeve Flange Failures May Go Unnoticed Cylinder sleeve flange failures may go unnoticed if the sleeve body stays in position, but if it is pulled down

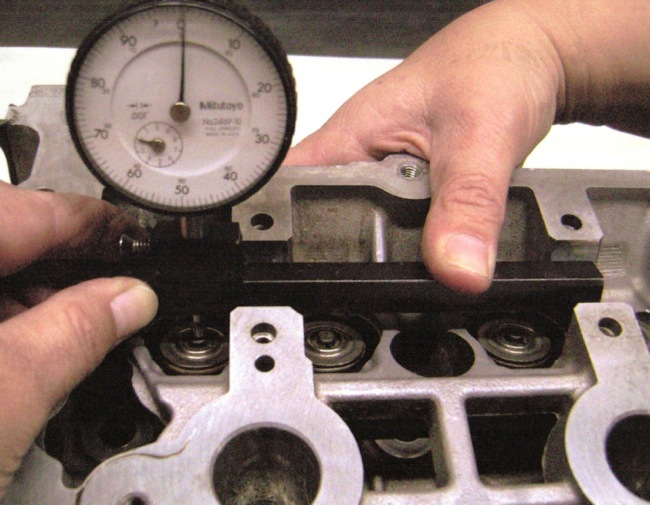

Surface Finish Testing: Dealing with Dirty Patches

Surface finish roughness instruments use a roughness specimen, or "patch," that is certified for a known wave form to provide a specific surface parameter result. With this certified specimen in hand, it is easy to verify that the surface finish measuring instrument is reading properly. Because of the nature of their sensitive probes, and because

Engine Builder Shop Solutions: July 2013

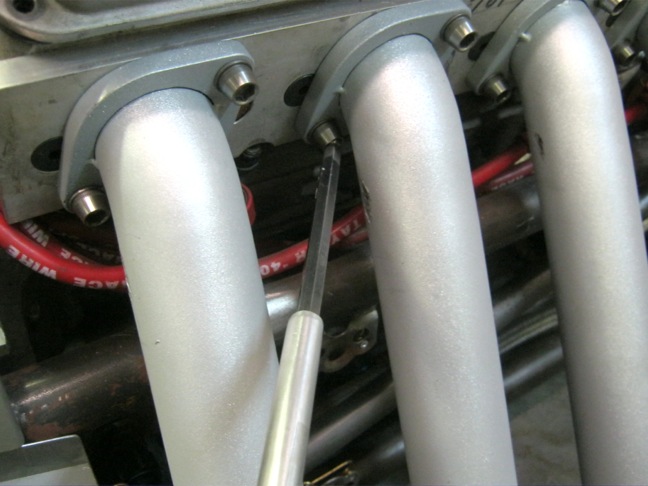

How to See Through Pistons for Clearance With the advent of longer stroke crankshafts, one inch plus lift camshafts, raised camshaft locations, lifter angles, bore spacing, etc., exact camshaft lobe and connecting rod clearance may not be able to be determined from looking up from the crankcase area of the block. To see through the

Engine Builder Shop Solutions: June 2013

Removing Stubborn Dowel Pins Do you ever have solid dowel pins that are worn or tapered, and the slap hammer slips off no matter how tight you make it? Add a dab of valve lapping compound to the dowel pin. It works wonders. Most of the time the pin slaps right out. Jeffrey Myers MAR

Engine Builder Shop Solutions: May 2013

Using Multi-Layer Steel (MLS) Head Gaskets As the name implies, MLS gaskets are constructed from 2 to 5 layers (depending upon the application) of heat treated stainless steel. Each layer is separated by a thin layer of a nitrile rubber coating. They have also been embossed in key areas to aid the sealing process, and to

Engine Builder Shop Solutions: April 2013

Making Your Own Piston Ring Compressor Some customers have been asking me for piston ring compressors in sizes we do not carry. My suggestion to them is to do what I do. Look in a cylinder sleeve catalog and find one that is close to the ID of the job you’re working on. Place the