My Cheating Heart

Like most racers, I was not keen on tech officials and some of the rules they enforced during my drag racing career. But in 2004, as my racing career was winding down, a friend named Chris McMahan, Operations Manager of RT. 66 Drag Strip in Joliet, IL, talked about having me come work for him on his tech official staff. That bizarre idea intrigued me – so I did it.

Connecting Rods

They say an engine is only as reliable as its weakest link. The connecting rods that join the pistons with the crank can be a strong link or a weak link depending on the rods that are used.

Foreign Exchange – Profiting From Import Engine Rebuilds

Today, vintage European cars are once again becoming popular, and often for the very same reasons that made them take off almost 60 years ago. Happily, along with increasing interest in such cars comes a rise in demand for engine rebuilding services.

Liners and Sleeves

Sleeves are certainly not new technology and experts say that, for the most part, engine builders and machine shops understand the use and functionality well. But is a liner and a sleeve the same thing? Is a hole just a hole? Publisher/Editor Doug Kaufman takes a deeper dive.

Sourcing Engine Blocks

Production engine builders today want engine cores that match a very specific vehicle application. In many cases, they also want the tinware that goes with the engine because the oil pan, valve covers and timing cover are also year, make and model specific. That has changed the way core suppliers have to inventory their stock.

Shop Solutions September 2015

Several types of Honda heads have a rocker panel with a set of three rockers together. These rockers have pins that can easily fall out and be lost once the rocker panel is removed from the cylinder head. Before removing the panel, use a small wire to hold the three rockers together.

Taking On the Internet

According to Engine Builder’s latest Machine Shop Market Profile, 56 percent of our readers don’t use a website for marketing and sales of their services. That needs to change. Here are some helpful tips to get your business into the 21st century.

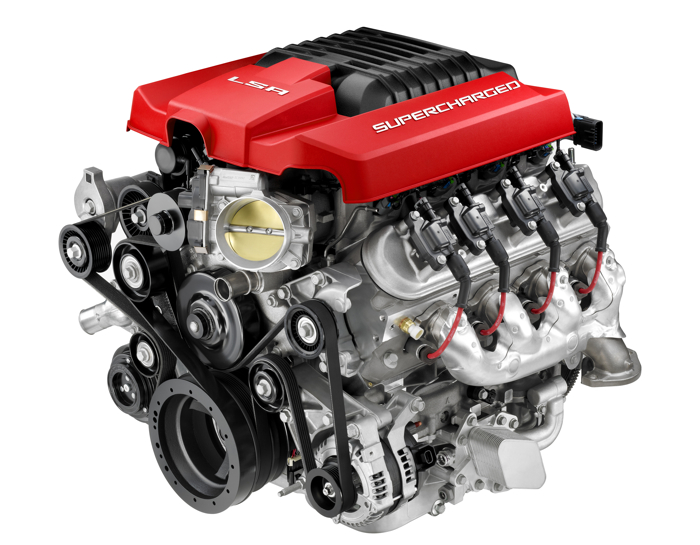

Chevy LS Family of Engines

This new engine family had the same bore spacing as the original small block, but that’s the only thing that stayed the same. The Gen III engine was smaller and lighter, it made more horsepower and torque per cubic inch, created fewer emissions and got better fuel mileage than the Chevy 350 it replaced. It was designed to be built in multiple displacements from day one so it could be used in a wide variety of cars and trucks later on.

Bischoff Racing Engines

Bischoff’s is the largest engine-building facility we have visited. Bischoff started the organization two decades ago with the main emphasis at the time on rebuilding stock engines. Over the years, the attention to performance kept increasing.

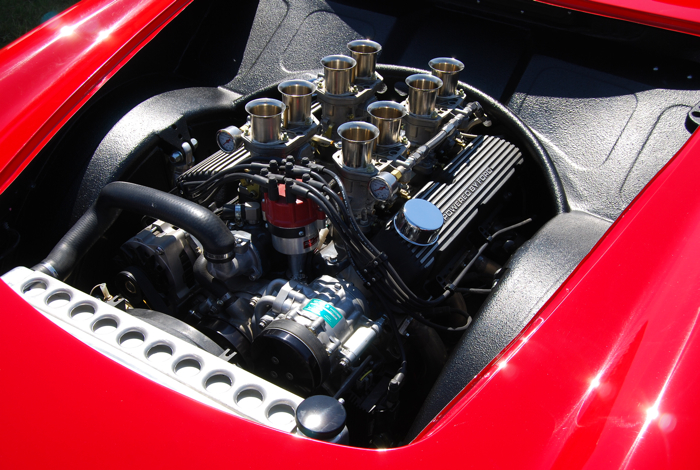

Carburetor and EFI Conversions

Carburetors have long served the performance aftermarket and racing industry well. Although they disappeared from new vehicles back in the late 1980s to meet emission requirements, it was only a couple of years ago that NASCAR finally abandoned carburetors in favor of fuel injection.

The Complexities of Modern Timing

Let’s face it: timing used to be relatively easy. These days, however, as with most every other engine component, the technology and innovation that leads to more fuel efficiency and performance also means increased complexity with timing components.

Motor Oil Issues

One of the challenges of building engines for a living is making sure that every engine you build has good oil pressure and suffers no lubrication-related issues once it goes out the door. Good oil pressure requires main and rod bearing clearances that are within your target specs for the application, a good oil pump and the “right” motor oil.