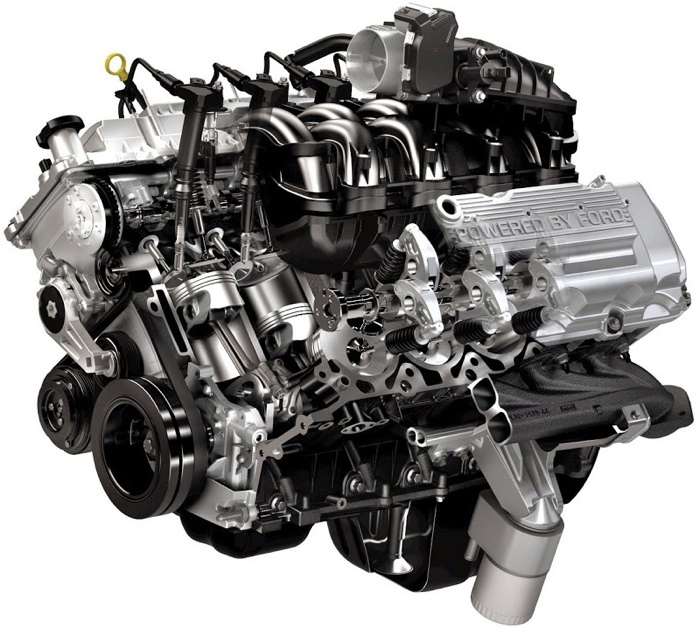

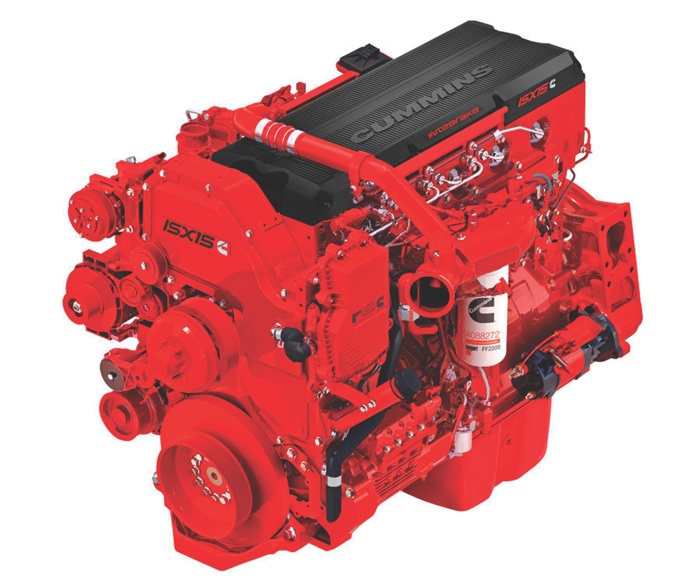

Performance Diesel Upgrades

Why should you offer more when rebuilding a diesel engine? Because any shop can rebuild the OEM block or buy a direct replacement. However, rebuilding a diesel engine with slight power modifications will get you more customers and offer you higher profits because of the modifications made that not everyone can do or has the knowledge to do.

Shop Solutions June 2015

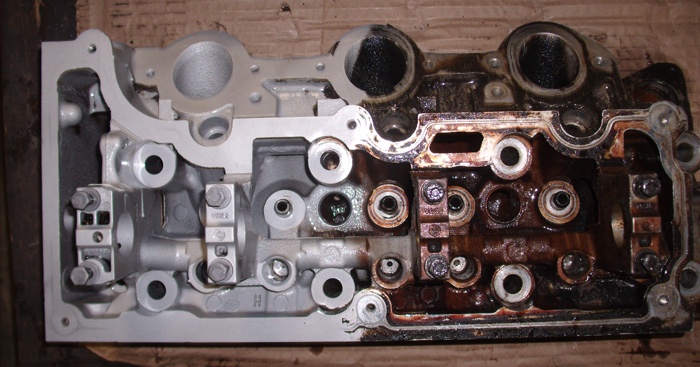

In our shop we do a variety of cylinder heads for late-model diesel trucks. On jobs like 6.0L Fords, 5.9L Cummins or 6.6L Duramax diesels our customers often install ARP studs as an improved fastener. ARP highly suggests that the studs be re-torqued after the engine is run for the first time.

How to Hot Rod a Fairmont

Once you’ve taken the time to wrap your brain around the terms “Fairmont” and “Hot Rod” in the same headline, you should read a little further. You’ll discover this story is not about a Ford Fairmont sedan, but rather a Fairmont Railroad Motorcar – the one built in Fairmont, MN.

CNG and Propane Engine Builds

Building engines for a living means building whatever a customer wants. With a growing market for alternative fuels you might find yourself building an engine for a customer who wants his engine to run on compressed natural gas (CNG), liquefied natural gas (LNG) or propane (liquefied petroleum gas or LP).

Engine Shops Are Cleaning Up

We’re engine builders and we live to get a little grease on our hands, right? While this is true, there is no harm in keeping your shop clean. In fact, there are numerous benefits to keeping your shop organized and clean. It makes a direct impact on efficiency, morale, the environment and most importantly, the customer.

Parts Coatings

Whether it’s more horsepower, better throttle response, or better durability, everybody is looking for an edge when it comes to building a performance engine. Any of these can win races. So what kinds of tricks are winning engine builders using to get an edge over their competitors? Many are using highly specialized coatings.

Being Green Takes Some ‘Engine’uity

You might not have even realized, but by being an engine builder/rebuilder alone, you’re already contributing to making the environment a greener place. That’s right, it takes less energy and less material to rebuild an engine than it does to build a brand new one. So since you’re already being ‘green,’ why not go a few steps further?

Building Stocks and Sprints

To be successful in the performance market, you need to deliver a product or service that a competitor not only needs, but will help make him a winner. To find that product or service, you need to spend time with them to understand the needs of the racers.

Cleaning Engine Parts

Cleaning is a time consuming, expensive process for most rebuilders. According to Engine Builder’s most recent Machine Shop Market Profile, rebuilders say they spend more than 15 percent of their total production time in cleaning. Safer, less toxic methods continue to gain a foothold in today’s professional shops.

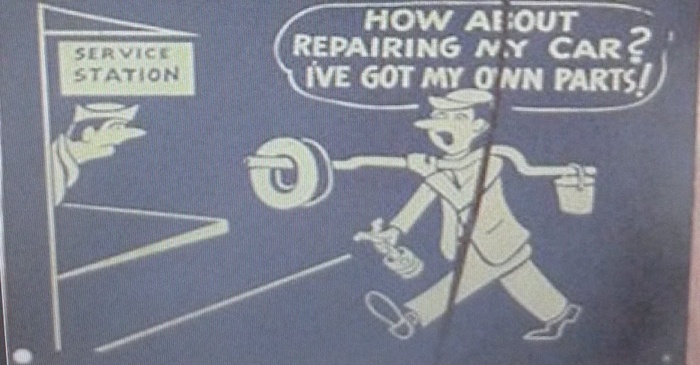

How Not to Lose the Race to the Bottom

You know how it feels when you explain something over and over and the person just doesn’t seem to get it? Some seven years ago I broke into the pages of Engine Builder with an article about dealing with what I called walk-in parts. Off and on again I’ve gotten back on that bandwagon because the topic just keeps getting more and more relevant.

Why Diesels Have Become ‘Greener’ and How You Can Benefit

For several years now, clean air and better fuel economy have been the primary focus of the transportation industry. Back in the 1970s, the clean air agenda came into full swing and it literally crippled performance as well as reliability. At that time, the diesel industry wasn’t being regulated by any of these emissions standards, but changes were on the horizon.

Shop Solutions April 2015

Hydraulic valve lifters are probably the most precision-machined part inside any engine. It does not take much to cause one to operate incorrectly. Here are some tips for fixing this problem, as well as some other helpful solutions to commonly seen shop scenarios.