Building the Ford GT 500 5.8L Engine

During an engine seminar at the 2017 PRI Show, we were introduced to Michael Rauscher, owner of L&M Engines in Hatboro, PA, who was on the panel of engine builders discussing engine oil and bearing performance. We were impressed with Rauscher’s responses and his philosophies on engine building, so we gave him a call to

Learning Engine Self Defense

All engines that are upgraded in horsepower, whether accomplished mechanically, with power adders or both, need to have the proper defensive steps in place or your now more powerful engine could suffer serious failures.

Race Engines Roar in Charlotte

Inaugural Challenge Brings Out The Best in Competitors and Combinations It may have been unseasonably warm in Charlotte, but engines (and builders) from around the country stayed cool under pressure as they were pushed to their limits in the inaugural Race Engine Challenge presented by VP Racing Fuels and Lubricants. After multiple days of pulls,

The Heartbeat of Performance

Wet or Dry Sump? The Answer is Science, Not Art You may have heard the analogy that the oil pump is the heart of the engine – as the heart pumps blood to keep us alive, the oil pump moves oil throughout the engine. A failure of either “heart” to pump its fluid properly will

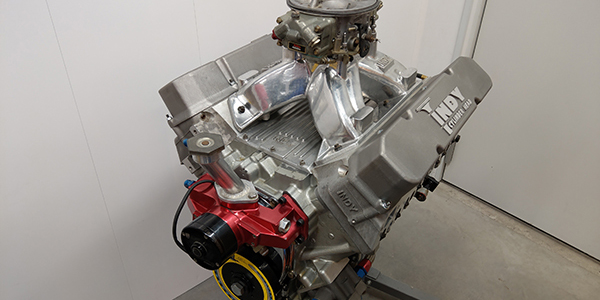

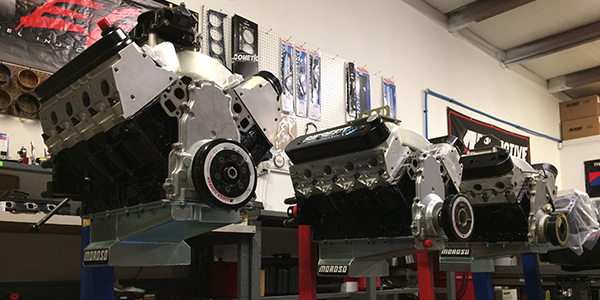

Building Stroker LS Engines

What is so great about these LS engines? First, the LS engine has multiple design features that help it achieve near-big-block levels of horsepower. With a 15-degree valve angle, intake ports that flow 300 cfm and a 55mm camshaft diameter, one can see what the engineers at GM were after when designing these engines – efficiency and performance.

Patterson Elite Builds LS Factory Showdown Champions

NHRA Factory Showdown pits 2008 and newer Camaros, Mustangs and Challengers that meet the COPO, Cobra Jet and Drag Pak designations against each other. Patterson Elite builds some of the best.

Engine Pro Shop Solutions – October 2018

PAPER CLAMP PIN CLIP Some piston pin clips can be a bear to install. If not supported right, the first one will push in too far or can be hard to seat. My solution uses office supplies to solve a shop problem. I lube and install the piston pin and then use the arm or

Engine Pro Shop Solutions – September 2018

DON’T SKIP THE DETAILS Sometimes it is just the little details that add up – and cleaning is key! Taking the time to use a little ATF to wipe your new piston rings down before assembly can help keep dirt and debris out of your new engine. Multiply this by the number of parts that

Engine Pro Shop Solutions – August 2018

LIFTER BORE CHAMFERING TOOL I purchased a 1˝ chamfering cone and welded a 6˝ extension to it. This is for chamfering the top and bottom of lifter bores in blocks. This saves time and leaves a better finish than doing them with a stone and grinder. Kevin Elam Liberty Machine Liberty, MO A QUICK TIP

Engine Pro Shop Solutions – July 2018

VALVE GRINDING TIP If you use a Sioux valve grinder or any valve grinder that centers on the chamfer of the end of the stem of the valve, it is very important that the chamfer is concentric with the valve. I have found the stem chamfer on some new valves are not concentric as I

Engine Pro Shop Solutions – June 2018

MAGNETIC CLEANER I attach a large speaker magnet in my valve grinder oil tank. This draws any metal particulate matter to this area and keeps the oil clean. Gary Sloat Auto Supply of Stuart Stuart, FL REAR END SETUP MADE EASIER After I read the article about the 12-bolt rear ends in an earlier issue of

Engine Pro Shop Solutions – May 2018

PISTON CLAMP Eliminating the movement of parts when installing or removing Spirolox-type retaining rings in piston and rod assemblies will make the job easier and save time and cursing. Instead of clamping a connecting rod in a vise and then trying to steady the piston, we make a simple device to stabilize the entire piston