Engine Builder Shop Solutions: April 2013

Making Your Own Piston Ring Compressor Some customers have been asking me for piston ring compressors in sizes we do not carry. My suggestion to them is to do what I do. Look in a cylinder sleeve catalog and find one that is close to the ID of the job you’re working on. Place the

Ready for a Diesel Resurgence?

Diesel engine building will soon see an increase in numbers – very soon! Why do I say that? In an effort to eliminate smoking engines and reduce emissions, the EPA came down hard on tuner manufacturers just a few months ago, issuing warning/cease notices on diesel particulate filters (DPF) and EGR delete tunes/kits.

Performance Gaskets & Surface Finishes

The most critical engine gaskets are the head gaskets since they have to withstand the heat and pressure of combustion. And unless the engine is a drag motor with a solid billet or filled block, the head gaskets also have to keep coolant out of the cylinders. Many performance engines are capable of making

Valve Seats & Guides

Most engine builders worth their salt know that with the components and technology available today, it’s not that difficult of a task to make horsepower. With the availability of so many performance parts – whether it’s from the OEM or the aftermarket – engine builders can pull from vast resources to achieve a balance between

‘Heads Up’ On Today’s Cylinder Heads & Bolts

Some say the air cleaner of an engine is like the front door of a house. That is, it’s what you see first and foremost. And the home owner can use that door to make a statement about the house without anyone seeing what’s inside. Much like what an air cleaner says about an engine

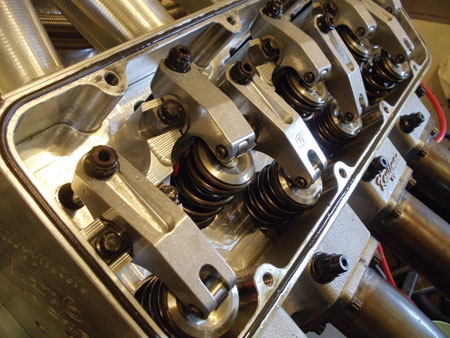

Valvetrain

Selecting the right components to make a rock-solid valvetrain is key to assembling an engine that will last – and win. The pushrods, rockers and valve springs must be able to handle all of the stresses of the camshaft rotating with high spring pressures and with huge lift. Weakness in any part of the system

Going Green Not Just for Irish

Did you know that as engine builders, we were green long before green became the IN thing? We were green even before Kermit said it wasn’t easy. How are we green, you ask? We are green because we rebuild, which means we recycle. Green is defined as: • Relating to or being an environmentalist

Not Quite a Full Pull

In tractor pulling parlance, a “hook” is when you attempt a pull. A “full pull” is one in which you go the maximum distance of 300 feet. At Engine Builder, we’re mourning one of our own, who made the hook, but didn’t quite get the full pull. Jim Walbolt, who had been a contributor to

Green Strategies: Cleaning Techniques & Equipment

It may seem that there’s nothing natural about cleaning an engine. Even after the couple of hours of cleaning time, the engine might be cleaner than the tech working on it – but the engine still needs cleaned (and so does the cleaning crew from time to time). We are long from the days of

Green Strategies: Recycling Scrap and Precious Metals

Engine rebuilding, arguably the truest form of recycling, restores core durability and is part of the 3 Rs: Reduce, Reuse and Recycle. In fact, the very definition of the word “recycle” could be interchanged with “engine rebuilding.” Recycling means to reuse or make (a substance) available for reuse for biological activities through natural processes of

Green Strategies: Efficient Shop Operations

If you really think about it, the engine building/remanufacturing industry is the true essence of going green. After all, you’re recycling: 1. A used product for further performance; 2. The solvents for other use; and 3. Your shop’s revenue as you have to make more profit from fewer rebuilds. “Most motors don’t run

Green Strategies: Handling Shop Waste

The amount of used oil and other hazardous solvents can pile up in a hurry when you’re hustling through the day’s engine work. Then you realize the space at the back of your shop is getting cluttered and your waste tank is filling up. It’s time to take care of the waste. From the early