Shop Solutions June 2016

We live in a time where aluminum blocks with cast-in sleeves are common and we still need to remember to account for how different metals behave. We build several dozen Gen III and Gen IV GM LS type motors per year. We finish our cylinders .001” tighter on the aluminum block engines to compensate for the additional growth when the block gets up to operating temperature.

Numbers Don’t Tell The Whole Story

Thankfully, many of YOU took time to give us an inside look at your businesses.

I Object!

Much can be learned consulting and comparing notes with colleagues and even clients. But carefully consider their comments and perhaps double check with another source to be sure their view is valid.

Reusing, Reclaiming, Remanufacturing

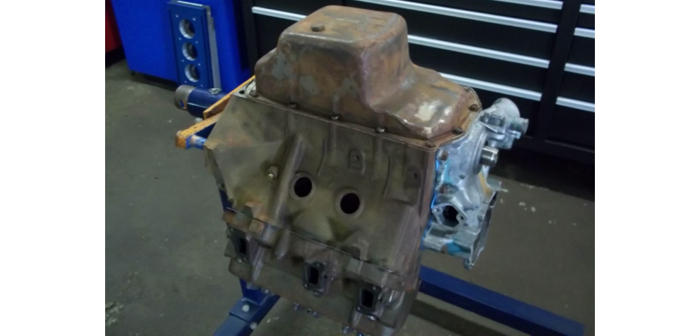

No matter what kind of engine builder or remanufacturer you may be or what applications you build for, at some point in time you’re going to run into a situation where a used engine part or component will come in handy.

Wet & Dry Sump Oiling Systems

Choosing the Right System for the Right Job

Industry Still Strong, Say Readers

Engine Builder readers tell us business has changed, but opportunity still remains.

Midget Engines

Midget open-wheel racecars and the Stock (S Class) and Modified (A Class) inboard hydroplanes have provided thrills and chills for racing fans since the 1930s. And as the speed and performance of these radically-different racing machines has improved, so have the engines that power them.

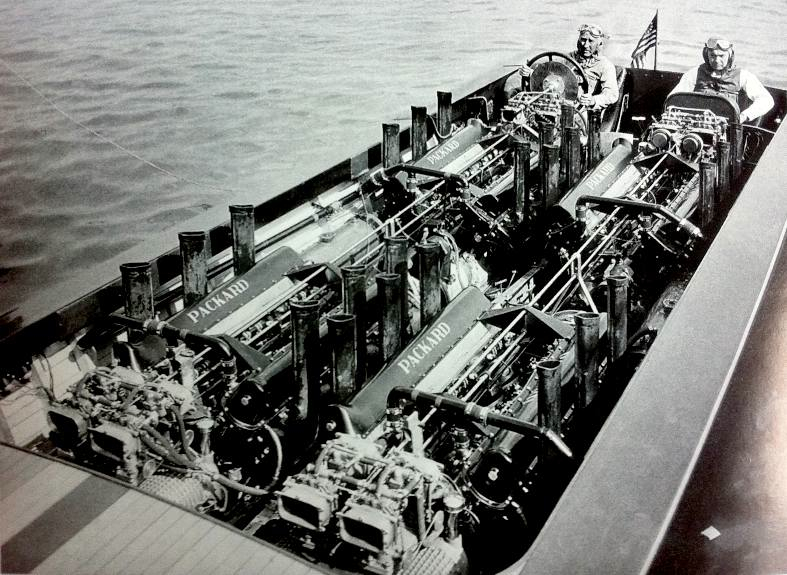

From a Dump Truck Dynasty Came a Speedboat King

Garfield Wood never intended to go into the boat building business. His goal in life was to personally set every speed record on water and be recognized as the world’s speedboat king.

A Job Well Done

If Timm Jurincie stopped accepting engine work today at his Avondale, AZ shop, Tuf-Enuf Auto & Marine Performance, he would still have enough work to last until September. Tuf-Enuf, which focuses on performance marine engines and street strip motors, is a sought-after engine shop in the Avondale and Phoenix area despite not advertising.

Understanding the Evolution of Cylinder Head Seat and Guide Machines

Do you remember the many generations of three-angle seat cutters and what we used to get by with? Grinding seats is still needed, but just 10 years ago we were grinding 80 percent of the seats. Though we still grind when necessary, today we cut 90 percent of the seats in the heads.