A New Year, A Fresh Start

Hey Engine Builder readers. I hope your 2024 is off to a nice start. What I love about the beginning of a new year is that everything is in front of you. There’s lots to look forward to. Although we’ve worked hard in the months prior to set editorial calendars, make plans for various pieces

Shop Solutions – January 2024

Before installing cam bearings, make sure to chamfer any oil holes and clean up back grooves of any sharp edges.

America’s Best Engine Shops 2023 | Warren Diesel Injection

For 13 years, Jesse and the team at WDI have been putting out stellar fuel system products and compete engines to the diesel community.

America’s Best Engine Shops 2023 | 955 Automotive

Operating out of roughly 3,500 sq.-ft. of space, 955 Automotive can handle anything that comes in the door, but the focus is on automotive restoration jobs and circle track engine work.

America’s Best Engine Shops 2023 | Noonan Race Engineering

Today, Noonan Race Engineering sits on 6.5 acres and has an 18,000 sq.-ft. manufacturing shop and a 16,000 sq.-ft. engine development shop, both of which are absolutely stunning, and the shop employs 13 full-time people.

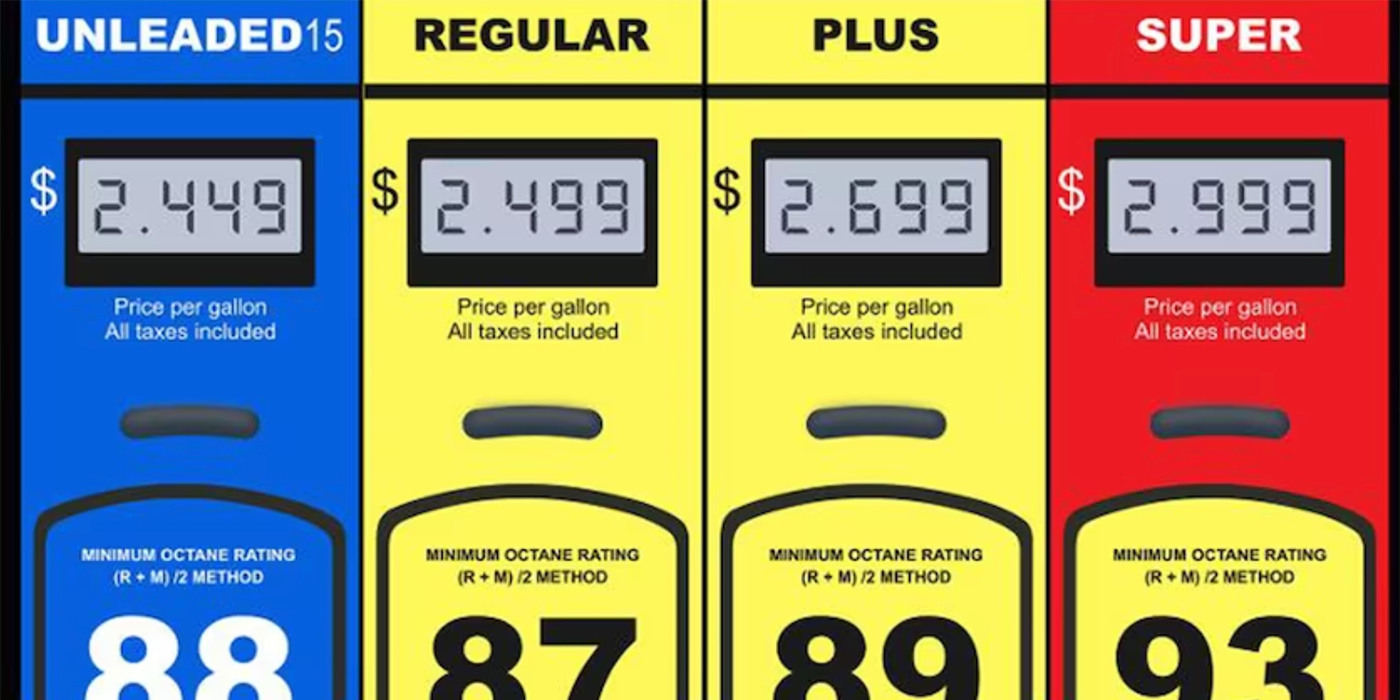

The Impact of Fuel Type on Engine Performance

When it comes to choosing the right fuel for your vehicle, several factors should be taken into consideration. These factors include the vehicle’s engine design, manufacturer recommendations, intended usage, and personal preferences.

Component Cleanliness

It can’t be overstated how important the cleaning machines are in the modern engine shop. Shop owners who prioritize effective and efficient cleaning techniques will find success in a more streamlined process.

Billet Blocks and Heads vs. Cast Iron

Billet aluminum has a lower yield strength or higher modulus of elasticity, meaning it will flex, or absorb energy easier under tension or stress than cast aluminum, without incurring permanent damage.

Shop Solutions November 2023

Many times, the flange diameter of the rod nuts will contact the radius around the nut seat on some rods. Some jobs may not warrant the expense of spot facing the nut seat on the connecting rods. In that case, it can be quicker and more effective to just machine a chamfer on the ARP rod nuts.

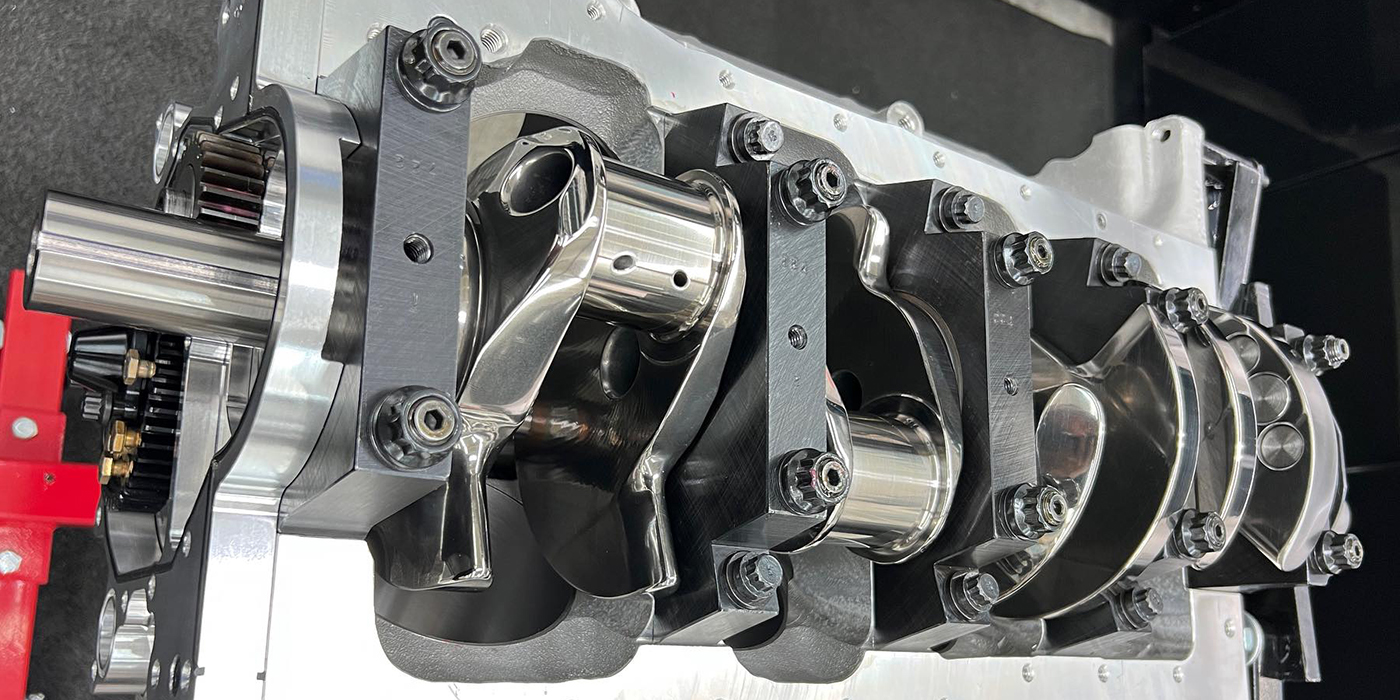

Crankshaft Counterweights

Most engines are internally balanced, meaning all weight adjustment is done on the crankshaft counterweights. However, some stock and modified engines require external balancing due to an increased stroke or larger pistons, and the crankshaft counterweights that would be required to offset the increased inertia simply don’t fit inside the crankcase.

Valve Springs

High-frequency fatigue, also known as harmonics, are a ubiquitous challenge in racing engines and can potentially wreak havoc on the valvetrain if left unchecked. Well-designed valve springs play a pivotal role in managing this, ensuring essential stability, and minimizing wear on valvetrain components.

The Latest on Lifters

For racing, a common trend to eliminate the problems associated with hydraulic lifters are the use of limited or short-travel hydraulic lifters. A reduction in plunger travel, which is usually about half that of a traditional full-travel lifter, reduces the amount of oil required to fill the lifter, which in turn reduces the compression of aerated oil.