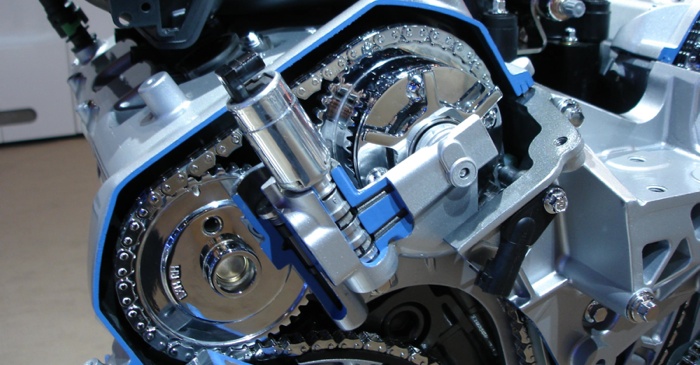

Timing Components

For metal parts to rotate, move, lift, bend, sway and – hopefully – not touch multiple times per second, every minute of every hour the engine is running takes more than just good enough – it takes precision that Swiss railroad conductors would envy. While everything in the engine has to precisely fit and accuracy is key, nowhere is precision more critical than in the timing.

Engine Block and Head Repair

A cracked cylinder head or engine block may or may not be bad news depending on the size and location of the crack(s), the value of the casting and what it will take to fix the crack(s) versus what it would cost you to replace the casting. Read what your options are in this Larry Carley feature.

Wisconsin Winners

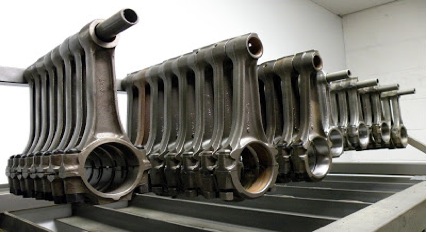

NVR is a race-oriented engine shop that builds mostly circle track and drag vehicle engines. With more than 40 years in the industry, Tom Nickerson works with his wife Cindy handling mostly Chevrolet builds, as well as other nameplate engines. NVR was named the 2014 Performance Engine Builder of the Year and we took a look at its operation.

Turning Over Industrial Engine Business

Engine builders today are diversifying their businesses in order to maintain a healthy, steady stream of business and cash flow. One such area of opportunity lies within the industrial engine market. Industrial engines are a broad category that essentially covers any off road engine. Read how your shop can get in on the action.

Who Do You Want To Work For?

Most of us that are shop owners get up, go to work, deal with customers and employees, answer the telephone, schedule jobs, order parts, and by the time we get that done in a day, it is past time to go home. But have you ever stopped to consider how a customer sees your shop? Why did he choose your shop over the one down the street?

Shop Solutions March 2015

Here’s a simple time saver for assembling high performance V8/V6 engines. When intake gasket port alignment is critical, use masking tape to hold the gasket in place on the head. You can then flip the gasket up to apply your sealer.