Engine Bearings Under Pressure

Today’s hi-flow, aftermarket, CNC-ported cylinder heads, high lift killer cams and induction system power adders (blowers, turbos and nitrous) are making more power than ever before, and really hammering the bottom end of the engine. If the bearings can’t take it, the engine won’t last.

The Racing Industry Gears Up for Indianapolis

Featuring roughly 1,200 exhibitors, the PRI Show highlights the latest advances in racing components, shop-machining equipment and engineering solutions, as well as special exhibits and seminars. There’s a lot to see, but it’s more than just the cool new parts, gadgets and equipment that make the trip to Indy worthwhile.

Oiling Systems for Grassroots Racing

Priority one when choosing an oiling system for any type of racing (grassroots or professional) is to establish what the rules allow and prohibit. Somebody has to read the rule book. Whether that’s you or your customer it doesn’t matter. The oiling system has to fit within the framework of the rule book. Period.

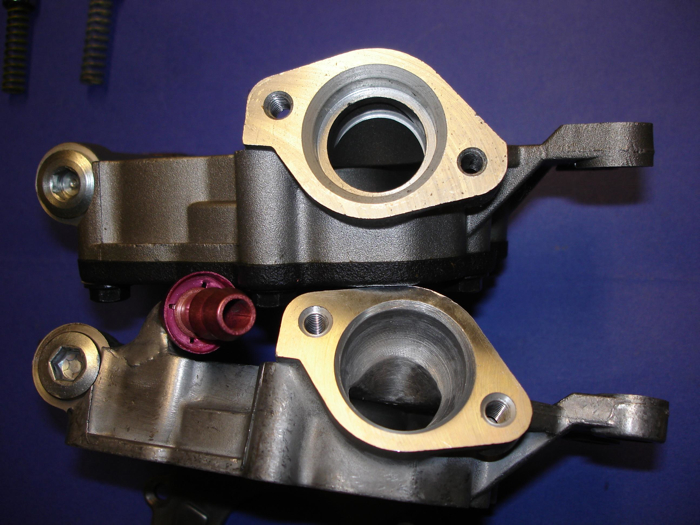

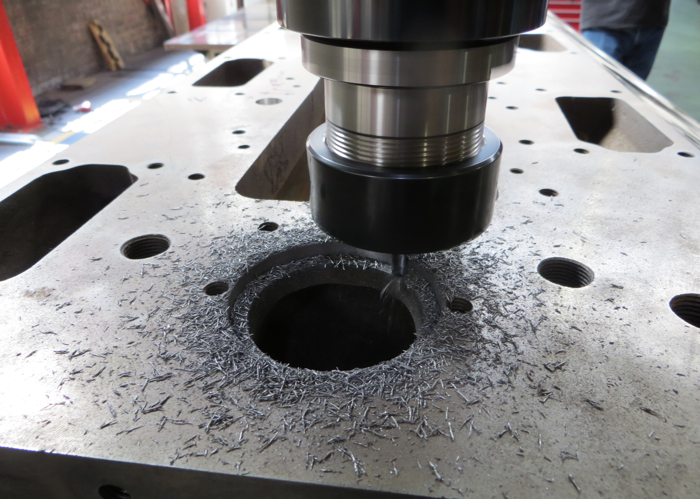

Modern Machining

Advancements in engine machining technology have truly moved this industry firmly into the space age. Highly developed abrasives and computer numeric controlled (CNC) software are found at almost every level of equipment, leaving some to mourn the loss of the “art” of engine machining in favor of the “science” of precision.

Super Class Act: Super Comp Engines and Drivers are a Different Breed

The three Super Classes are the only ones allowed a throttle stop. In the beginning of the Super Class fixed index racing history, racers had to set up the car and physically control their driving in order to run as close to the index as possible. When the throttle stop entered the picture, things changed drastically.

Shop Solutions November 2015

When assembling an engine, one of the most overlooked items is the timing chain sprocket alignment. The upper and lower gears should be installed and alignment checked with a straight edge. I have seen them as far as .020˝ off.