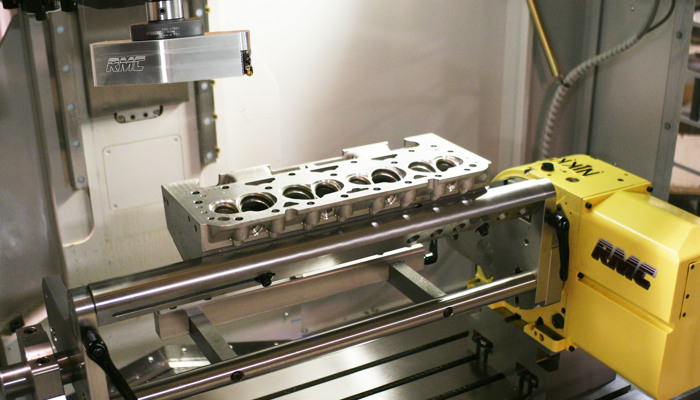

Head and Block Resurfacing Equipment

Regardless of what type of engine work you do in your shop (stock, performance, diesel, marine or anything that comes in the door), you need the ability to surface heads and blocks. Deck surfaces on high mileage heads and blocks are often corroded, pitted, scratched and/or out-of-flat – especially if the engine blew a head gasket or overheated.

Aftermarket Diesel Innovations

Diesel technology has come a long way, evolving from smelly, dirty, slow, workhorse engines to clean-burning, high-torque, high-horsepower engines that can give many gasoline engines a run for the money on a drag strip or race track.

Understanding the Evolution of Cylinder Head Seat and Guide Machines

Do you remember the many generations of three-angle seat cutters and what we used to get by with? Grinding seats is still needed, but just 10 years ago we were grinding 80 percent of the seats. Though we still grind when necessary, today we cut 90 percent of the seats in the heads.

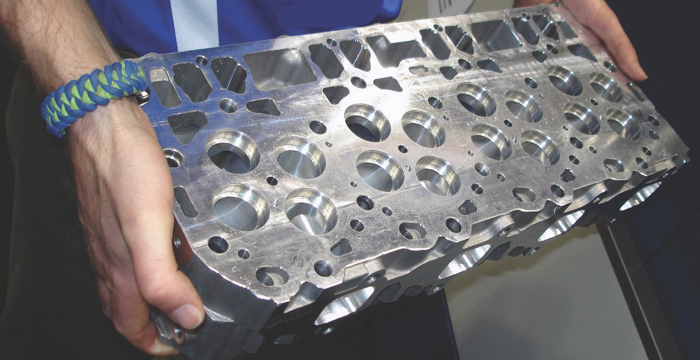

Cylinder Head Design, Selection for Engine Builds

Choosing the “right” cylinder heads for an engine build can make all the difference in an engine that delivers and one that falls short of its potential. Horsepower, torque and throttle response all depend on how well the cylinder heads, camshaft and induction system work together. Choose the right combination and you’ll build a winner.

Shop Solutions – April 2016

To make the glass in our glass-beading machine last longer, we cover the inside with duct tape, leaving a small open port to view the work. When this gets cloudy, we remove another small piece of the tape. Our glass lasts much longer now before it needs replacing.

How to Find and Fix Cracks

Cracks are bad news because they never heal themselves. Once a crack starts, it always gets worse. Checking critical engine parts and castings is time well spent if it heads off a major problem that might result in a major engine issue or a warranty claim.

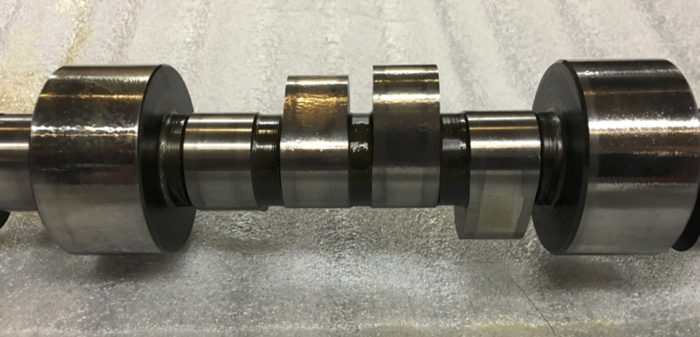

There’s No Simple Formula to Choosing the Perfect Camshaft

The camshaft design affects valve timing, compression and the engine’s ability to breathe. From pistons to manifolds, valve grind, piston pin offset, rod length, etc. Once the camshaft has been tabbed correctly for the application, the rest of the build can focus off that selection.

Riding Into a New Engine Market

It’s no secret that there are engine-building opportunities that lie outside of the automotive industry. One such example is with motorcycle and powersports engines. This is a well-established market with numerous OEMs and styles of vehicles with many similarities to the automotive side, yet not many shops choose to explore this market. But if opportunity knocks and you answer the call, you could very well come out on top.

QualCast, LLC Heavy-Duty, Agricultural and Industrial Catalog

QualCast has updated and extracted all Heavy-Duty, Agricultural and Industrial applications from its master catalog to create the first valve train specific Heavy-Duty catalog in the aftermarket. A total of 34 engine manufacturers, 394 engine lines and 1871 part numbers are included in the catalog.

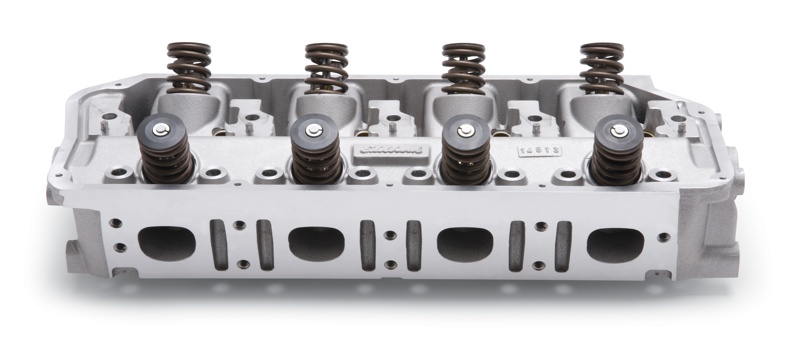

Edelbrock E-CNC Cylinder Heads for Chevy LS3 Engines

Edelbrock has expanded its line of E-CNC cylinder heads to include an application for the Chevrolet LS3 engine. Edelbrock E-CNC LS3 cylinder heads feature altered valve angles and locations, spark plug location and valve sizes along with all-new, high-flow ports and chambers.

Shop Solutions April 2015

Hydraulic valve lifters are probably the most precision-machined part inside any engine. It does not take much to cause one to operate incorrectly. Here are some tips for fixing this problem, as well as some other helpful solutions to commonly seen shop scenarios.

More Power Inside – Muscle Cars

There are many aspects of the famous and desired muscle car engines of the 1960s and ‘70s. They have become the holy grail of factory performance engines, but they are getting more and more scarce as the years go by. For car owners, the engines have evolved in recent years into three different configurations. Read on to learn more.

Choosing the Right Camshaft for a Performance Engine

A camshaft is nothing more than a cast iron or steel shaft with a series of lobes strategically placed along its length. Each lobe opens and closes a valve by moving a lifter, pushrod and rocker arm, or in the case of an overhead cam engine by moving a cam follower or direct valve action. However, choosing the right camshaft is not only the cornerstone of building a performance engine, but also its centerpiece.

Edelbrock Victor Jr. CNC Cylinder Heads for HEMI Engines

Edelbrock’s new Victor Jr. CNC cylinder heads are designed for high output 650+ hp Chrysler 426-572 HEMI engines. They feature fully CNC machined 170cc combustion chambers and seats CNC blended into cast ports for optimal performance. They also feature a 245cc intake runner volume and a revised exhaust valve angle to accommodate larger intake valves.

The 392 Magnum V8 Build is a Wrap

The 392 Magnum engine build is a wrap. We’ve done all we can and now it’s going to power someone’s muscle car, hot rod or truck. When all is said-and-done the only things original in this 318 motor are a fully machined block, the cam thrust plate, the fuel pump eccentric and the bolt and washer holding on the harmonic balancer. Everything else is brand new.

Sticker Shock – The 392 Magnum Gets Ready for Auction

As you can see in the pictures, we’ve reached a point where we can say the engine is built and ready to install. Or in this case ready to dyno and auction off. We certainly would not have been able to produce such a cool piece without the help of our contributors and Grawmondbecks Competition Engines. The 392 V8 Magnum engine is currently being auctioned off on eBay Motors. The auction ends Dec. 21.

Choosing the Correct Camshaft for the Build

Choosing a particular type of camshaft for an engine build is an important decision that has to be made before any other parts are ordered or machined. Choosing a cam requires answering some basic questions, the most important of which is the engine application itself.

Melling / Dura-Bond

The Melling story began in 1946 in Jackson, MI, when George Melling Sr. and his son Ben started production of aftermarket oil pumps. In 1952 they introduced the first high-volume oil pump, which revolutionized the automotive aftermarket industry for oil pumps. In 1975, Harry Melling took over the company as the third generation president. Harry’s

Must Have Shop Tools & Measuring Equipment

You can’t do quality work in an automotive machine shop if you don’t have the right tools and measuring equipment. “Must have” tools and equipment include those that are necessary for engine disassembly, for inspecting and measuring engine components, and for engine assembly.

Kaase Introduces Boss Nine Engine Kits for Common Ford 429-460 Big Blocks

For engine builders, and enthusiasts with ambitions in hot rod engine assembly, Jon Kaase has introduced the Boss Nine in a new kit form. Among the kit’s more prominent components, Kaase includes his noted semi-hemi cylinder heads with accompanying pistons, pins and rings as well as pushrods, shaft-mounted rockers and induction system. Everything to complete