Taking the Guesswork out of Rotating Assemblies

Rotating assemblies often turn into a guessing game as enthusiasts struggle to find the right option for their project. No matter who it is buying a rotating assembly, there are a few key factors to consider before making all your selections.

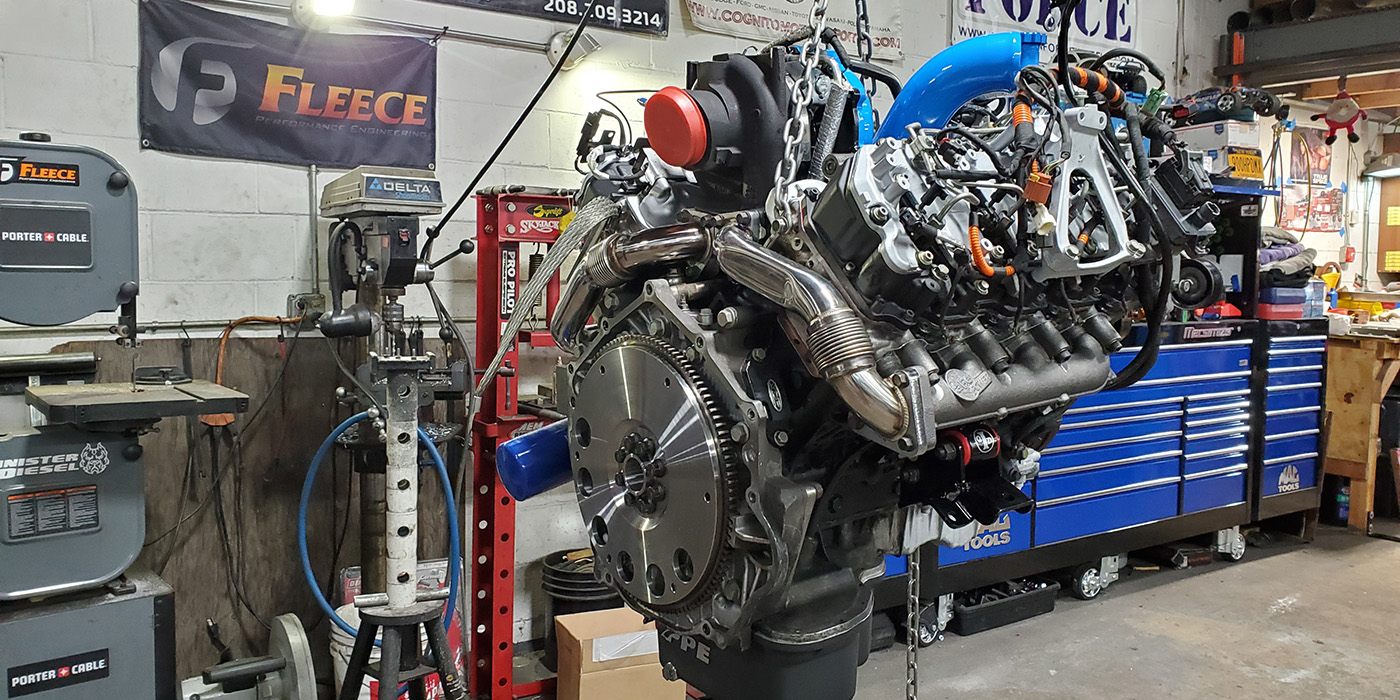

Dissecting 6.6L Duramax Engines

Whether you’re looking for fun or looking to win, the Duramax platform is certainly one to consider. The Duramax engine is can be built up to do just about anything you want. The only obstacle is your wallet.

What is Saenz Performance?

Saenz products have helped win more than 100 championships worldwide, and with over 50 years of experience in manufacturing and 40 in the motorsports market, Saenz stands behind its products.

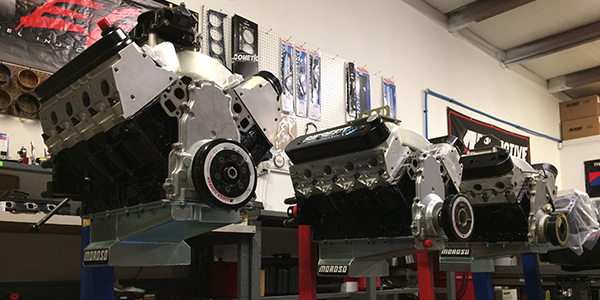

LS Engine Parts Selection

People in the aftermarket thought that the SBC could never be replaced, but in the eyes of many hot rodders and engine builders, the heir to the throne is the LS platform.

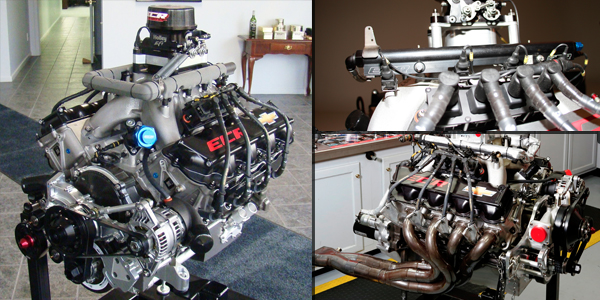

Endurance Racing = Engine Punishment

Ten years ago, building an offshore powerboat engine was considered the most demanding job ever; Hands down. The combination of weight and size and the boat bouncing over waves causing the props to lunge in and out of the ocean, made for one tough customer. Until now.

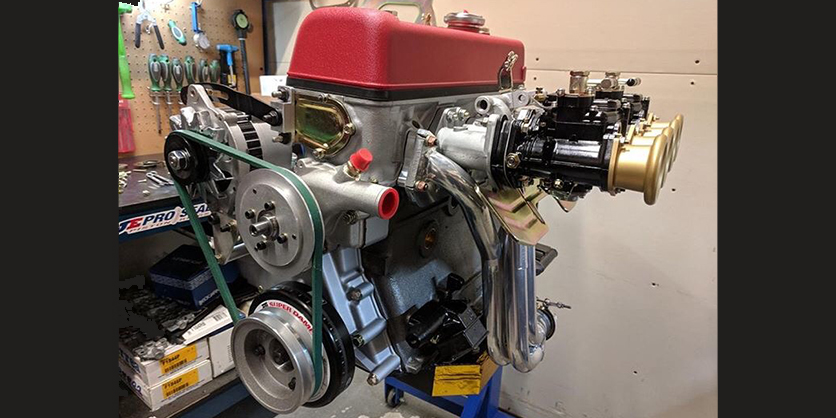

1960s Nissan/Datsun U20 Engine

Mitchell Wilson recently had a first time customer get referred to his shop, Engineered Performance, to do the engine work on a 1960s Nissan/Datsun U20 engine. The build presented a unique challenge and Wilson jumped at the opportunity. Find out what it took to turn this vintage engine into a modern-day performance motor.

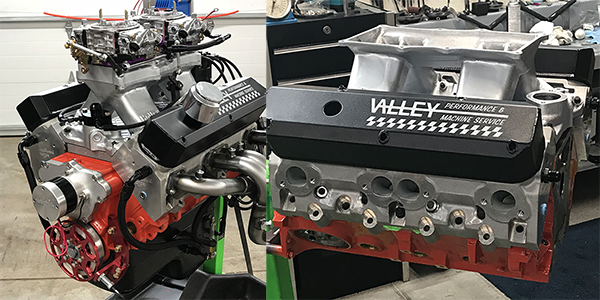

376 cid Mopar Engine

Building engines for customers is what pays the bills, but its not very often that engine builders get to go head-to-head for bragging rights outside of the racetrack. So when Jack Barna of Valley Performance and Machine Service heard about the Race Engine Challenge, he wasted no time putting together this 376 cid Mopar engine. Find out what went into the build and how he faired on the dyno!

Building Stroker LS Engines

What is so great about these LS engines? First, the LS engine has multiple design features that help it achieve near-big-block levels of horsepower. With a 15-degree valve angle, intake ports that flow 300 cfm and a 55mm camshaft diameter, one can see what the engineers at GM were after when designing these engines – efficiency and performance.

Patterson Elite Builds LS Factory Showdown Champions

NHRA Factory Showdown pits 2008 and newer Camaros, Mustangs and Challengers that meet the COPO, Cobra Jet and Drag Pak designations against each other. Patterson Elite builds some of the best.

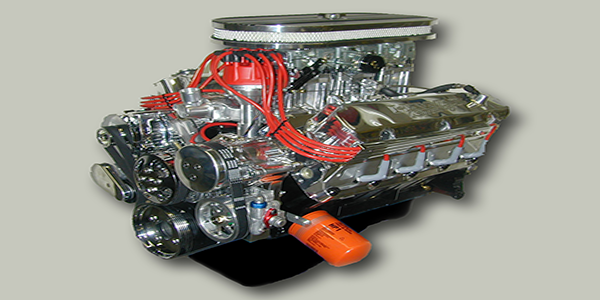

The Art of the Engine

It’s sometimes called the “Second Great Minnesota Get Together.” It’s not as large a gathering, nor is it as long as the State Fair, but for three days people come from many states around to attend the MSRA Back-to-the-‘50s car show. The Minnesota Street Rod Association hosts this annual car freak extravaganza, open to cars

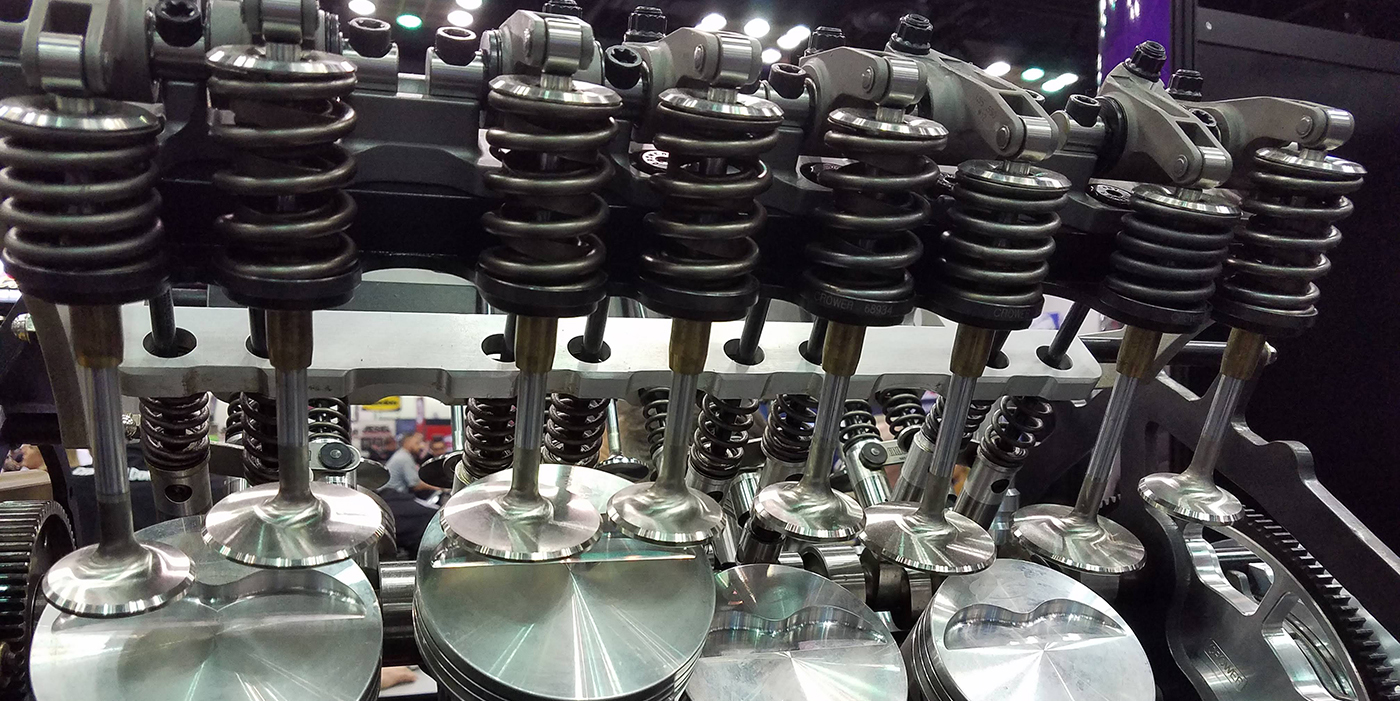

Rotating Assemblies

Sourcing Rotating Assemblies for Stroker Applications Stroker engines are a popular choice for performance enthusiasts – whether the vehicle will run on the street, strip or a little of both, there’s something for everyone to love about a stroked engine. First of all, it sounds cool. Customers love telling their friends that they have something

Sprint and Stock Car Engine Market

Building engines for sprint cars and late-model stock cars is a good niche to be in if your local tracks have a strong racing program that is attracting significant numbers of racers and fans. It takes both to maintain a healthy market and a steady demand for engine work.

An In-Depth Look at Crankshafts

In every aspect of an engine, strength is a very critical factor in the life span and performance level that it can achieve. One place in particular where strength is the most important consideration is the crankshaft.

Buying Behavior – Who Buys What and How

With more vehicles on the road, more engine configurations under hoods and more parts on the shelves, the process of getting engine parts from manufacturer to end user has never been more complicated.

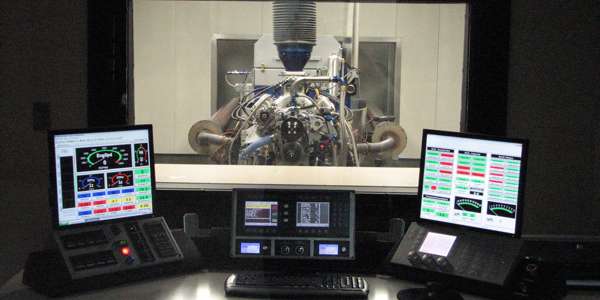

A Day in the Life of a NASCAR Engine

At the Monster Energy NASCAR Cup level, it’s no secret that the competition is fierce. Every little thing matters from the driver to pit stops to one of the most important aspects – the engine. Engine Builder recently got an inside look at engine development at Earnhardt Childress Racing (ECR) from Andrew Randolph, ECR’s technical director.

NASCAR Cup Series Chevrolet 5.8L V8 Engine

At the NASCAR Cup Series level, teams are trying to get any extra horsepower they can. Earnhardt Childress Racing uses its engine development philosophy to find half, one and two-horsepower gains for its Chevrolet R07.2 5.8L V8 engine.

Racing Rods – Engine Builders Have Options

Choosing a set of connecting rods is one of the critical steps in a performance engine build. The rods have to be strong enough to handle the anticipated speeds and loads, but also affordable for customers who have a limited budget. Most stock rods in late model engines can safely handle 400 to 500 horsepower.

Preventing Connecting Rod Failures

Connecting rods are some of the hardest working parts inside an engine. Fortunately, rod failures from severe overloading don’t happen that often. However, they can occur in racing or extreme street performance applications. So here’s what you need to know.

Racing Rod Options

Choosing a set of connecting rods is one of the critical steps in a performance engine build. The rods have to be strong enough to handle the anticipated speeds and loads, but also affordable for customers who have a limited budget.

Connecting Rods

They say an engine is only as reliable as its weakest link. The connecting rods that join the pistons with the crank can be a strong link or a weak link depending on the rods that are used.