Penske Unveil Traveling Stem Center

Penske Truck Leasing has donated a specially equipped 26-foot Freightliner M2 box truck to house and transport the new TechForce Foundation Mobile STEM Career Center. The Center is a traveling, hands-on exhibit designed to engage and help Gen Z discover a rewarding career path as professional technicians in the transportation field. “Although we developed the STEM

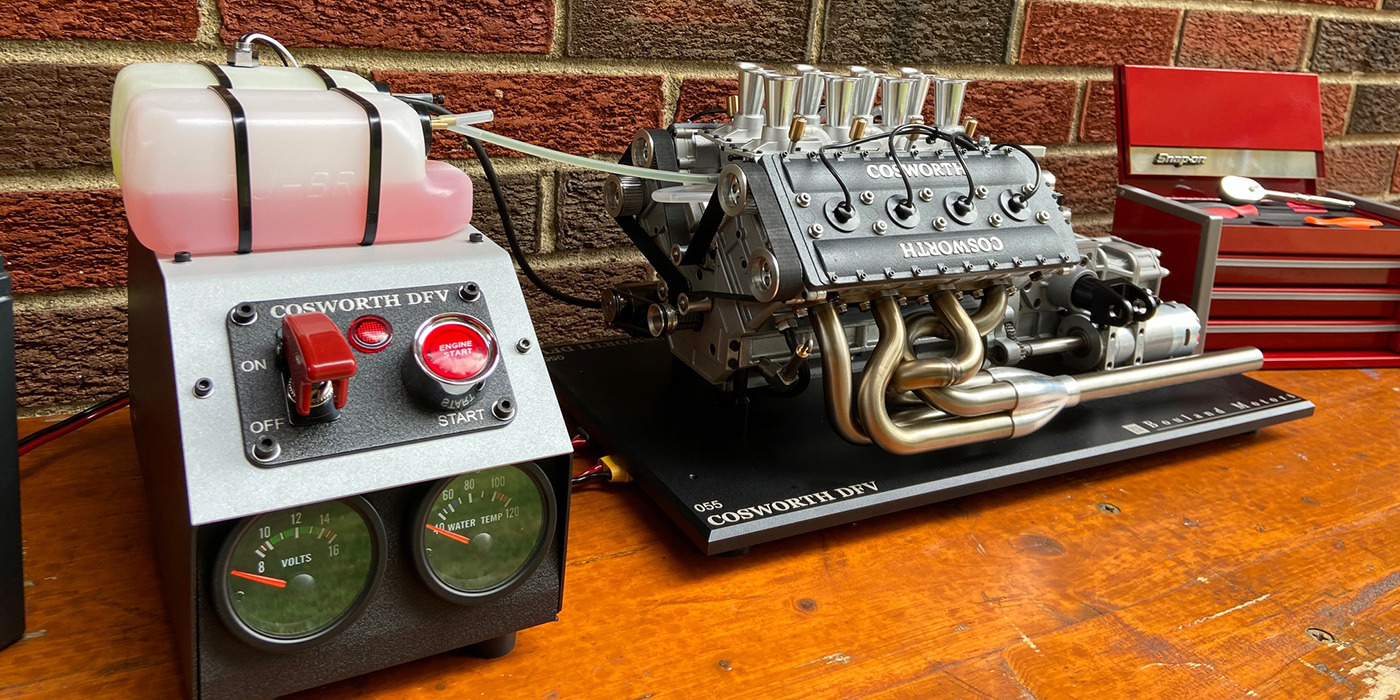

1:3 Scale Cosworth DFV V8 Engine

With its success, the Cosworth DFV V8 engine is considered one of the most legendary F1 engines ever, and has since inspired many in the automotive racing world. One such person is Marcel Bouland, a scale model engine enthusiast and collector from the Netherlands, who decided to develop a fully working 1:3 scale Cosworth DFV engine.

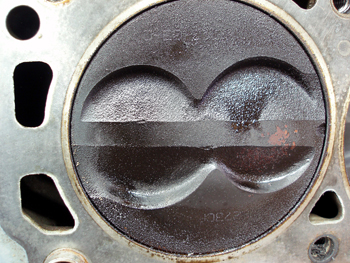

Giving Old Pistons New Attitude

I find great joy in creating the pistons I make, and in the joy they bring others. I believe every piston heading to the scrap heap has a story to tell. I try to leave behind imperfections or damage when possible to help preserve the history of the piece.

G&R Diesel – Engine Builder Profile

G&R Diesel first opened in 2008 working on class 8 trucks, but with a strong market and the growing popularity of diesel pickup trucks, it wasn’t long until they added diesel performance to their list of services.

PRO-LINK Ultra Cummins Software Features Expanded Engine Coverage

The PRO-LINK line is a heavy-duty diagnostics system that assists technicians in diagnosing heavy-duty vehicles, allowing engine builders to pinpoint the problem, saving valuable shop time.

The Valve Refacer

Let’s talk about the valve refacer. I mean you all have one. Some of you have two. My question today, is what is the program in your shop to maintain that piece of equipment?

The Daily Grind – Grinding valve seats with different abrasives

Grinding valve seats with abrasive stones has been aound about as long as the internal combustion engine. In the early days of grinding seats, there were only two abrasive materials to choose from – General Purpose and Finishing – because seats were mostly made of a single material, cast iron. Today, seats are made of

CRP Automotive Names Cory Martin West Coast Regional Sales Manager

CRP Automotive has announced that Cory Martin has joined CRP Automotive and will serve as the regional sales manager for the western region of the United States. Martin will be based out of the San Francisco Bay area and will be responsible for all sales activities, account management, and product training for West Coast customers.

The Daily Grind

Today, seats are made of a wide variety of materials, different combinations of various alloys, powdered metals and other super hard materials. This seat material is designed to prolong the ability of the valve seat to seal against the pounding of the valve head during engine operation. The variety of materials also means new and different abrasives are required for proper machining.

Old Gold – Vintage Engine Analyzers and Distributor Testers

Engine analyzers and distributor testers are the most common types of equipment seen in the old-car hobby. Of the two, the distributor tester seems to be the more desirable and valuable type of machine.

Bill Hoffpauer Joins CRP Automotive as Regional Sales Manager

CRP Automotive has announced the appointment of Bill Hoffpauer as its Regional Sales Manager for the Southeastern US. Hoffpauer has taken over the responsibilities of CRP Automotive’s former Southeast Manager, Daniel McSwain, who has retired.

Diagnosing Engine Noise Under The Hood Of A Ford F-150

This article is about diagnosing a mysterious engine noise in a 1989 Ford F-150 pickup equipped with the venerable 5.0L or 302 cubic-inch V8 engine following a rebuild. Most of us working in the automotive service trades are very familiar with Murphy’s Law and how it affects our shop’s cost of doing business. Murphy’s Law

Torque Wrench Maintenance and Usage Tips

Guidelines are typically provided noting acceptable torque ranges, theorder in which specific fasteners are tightened and the number of timesa fastener must be tightened and loosened to ensure uniform torqueapplication. Failure to properly torque fasteners can lead toequipment damage, personal injury or worse. It is important to follow acceptable maintenance and use practices, such as:

COMP Cams Engine Builder Duel Returns To NSRA Street Rod Nationals Aug. 2-5

The 2012 NSRA Street Rod National participants will get a chance to showoff their engine building skills in the COMP Cams Engine Builder Duel this weekend, Aug. 2-5, at the Kentucky Exposition Center in Louisville,KY. The event annually features over 11,000 street rods and more than 30,000 visitors. The Engine Builder Duel, presented by Snap-On

Proper Torque Wrench Use and Maintenance

A torque wrench is a precision instrument designed to apply a specific amount of force to a fastener. Whether tightening head bolts on an automobile engine, lugs for tire and rim installation or inspecting fastener tolerances on high-performance equipment, it is extremely important that proper care is used. Guidelines are typically provided noting acceptable torque

Tech Notes

Engine Builders: What does SAE 10W-30 actually mean? We all know to check the owner’s manual to find out which weight oil should be used in the engine of a vehicle, and also generally know to only use motor oils with American Petroleum Institute Certification, designated by the starburst displayed clearly on the container, in

Coretalk: Cummins, Scania Joint Venture To Produce Next-Generation Fuel Systems

Cummins-Scania XPI Manufacturing LLP is a 50/50 joint venture, which builds on Cummins-Scania partnerships in fuel systems development and manufacturing that date to January 1992. The two companies currently produce the HPI fuel system, which eventually will be replaced by the XPI (Xtra-High Pressure Injection) system. The XPI common rail fuel system is expected to

Ford’s 4G Alternator: IAR Series & The New 4G

When one considers the Ford IAR series of alternators,then examines the new 4G alternator, it seems that Ford went overboardto correct all the problems with the IAR series. The IAR series was designed for rapid assemblyand disassembly with plenty of snap-on connectors and mountinghardware. With this design approach came problems, particularlywith the burnt out B-S-S