Reusing, Reclaiming, Remanufacturing – Whatever you call it, it’s how the industry recycles parts and components

No matter what kind of engine builder or remanufacturer you may be or what applications you build for, at some point in time you’re going to run into a situation where a used engine part or component will come in handy. You’ll reuse, reclaim or remanufacture it for your specific job. Whatever the reason may

Top Fuel Racing Engines – Containing the Explosions

It’s been over 60 years since Vic Edelbrock starting experimenting with nitromethane as a racing fuel in the early 1950s. In the 60 years of hands-on education since, along with the help of modern technology, there have been some amazing results. Earlier this year, I wrote a Memory Lane column titled “Going Faster in 1954”

Chemical Cleaning – Solvents and Aqueous Products Are Still Popular Choices: Here’s Why They Work

Cleaning is a process that no engine builder can avoid, whether you are rebuilding high mileage engines caked with gunk and full of gunk, or you are working with all brand new components and castings.

Revved Up – Why the Import Engine Market is on the Rise

For numerous reasons in recent years people have been fixing engine issues rather than replacing engines altogether, making for a strong outlook in the import engine market. There are several ways you can break into this market or improve your stance here if you’re already an import engine builder.

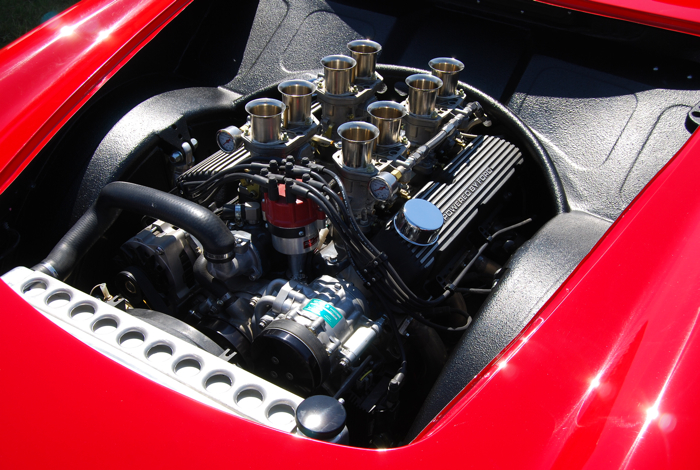

Hot Engines for Hot Wheels – the Reality of Building Engines for TV

If one of the most recognizable hosts of one of the most popular automotive-based reality TV shows came calling and asked you to build a blown big block to squeeze into a vintage collector car to help celebrate the history of an iconic toy, would you blink? For Jammie Wells, it’s just another day in the shop.

Hot Engines for Hot Wheels

If one of the most recognizable hosts of one of the most popular automotive-based reality TV shows came calling and asked you to build a blown big block to squeeze into a vintage collector car to help celebrate the history of an iconic toy, would you blink? For Jammie Wells, it’s just another day in

Foreign Exchange – Profiting From Import Engine Rebuilds

Today, vintage European cars are once again becoming popular, and often for the very same reasons that made them take off almost 60 years ago. Happily, along with increasing interest in such cars comes a rise in demand for engine rebuilding services.

Is Non-Destructive Cleaning Critical? ARMEX is the Only Choice

When part specifications and surface tolerances cannot change, the only blasting abrasive to use is ARMEX. The gentle physical propriety of baking soda, yet aggressive cleaning ability is what makes ARMEX the only choice.

Engine Shops Are Cleaning Up

We’re engine builders and we live to get a little grease on our hands, right? While this is true, there is no harm in keeping your shop clean. In fact, there are numerous benefits to keeping your shop organized and clean. It makes a direct impact on efficiency, morale, the environment and most importantly, the customer.

Being Green Takes Some ‘Engine’uity

You might not have even realized, but by being an engine builder/rebuilder alone, you’re already contributing to making the environment a greener place. That’s right, it takes less energy and less material to rebuild an engine than it does to build a brand new one. So since you’re already being ‘green,’ why not go a few steps further?

Engine Break-In Oil and Assembly Lube Needs

Engine building is a process that should go well when everything is done correctly. A lot of things can go wrong during those first few minutes following the initial start-up of a freshly built engine. The engine has to build oil pressure quickly so all of the critical wear surfaces will receive lubrication.

Green Strategies: Recycled Engine Parts Save Profits

The list of reclaimed bare engine blocks on the Kenmonth Engine Company website (www.danamotorssac.com) is enough to warm the heart of any vintage vehicle collector. There’s an AMC 401-cid big-block for $800, five 1959 thru 1966 Buick “Nailheads” for $450 each, a 390 for a tail-finned ‘59 Caddy for $450, a 216-cid Chevy “Stovebolt 6”

Green Strategies: Recycling Options for the Engine Shop

Recycle or dispose. What’s the difference? It’s just trash, right? Not really. The old adage of “one man’s trash is another man’s treasure” profoundly rings true in automotive aftermarket’s own recycling niché: engine building. We know you set aside your metals from a wide range of vehicle repairs and modifications, but when it comes to

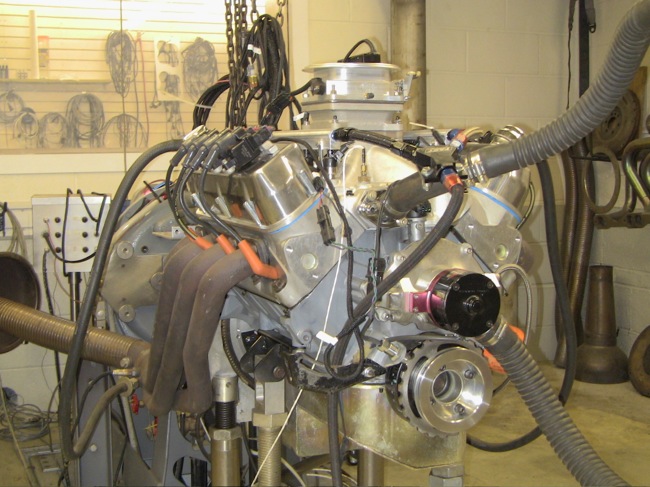

Dyno-Might: Utilizing a Dynamometer to ‘Boost’ Engine Builds

Some would say that one of the criteria for being a “real” performance engine builder is having your own engine dyno. A dynamometer is not just a tool for measuring horsepower and torque (though some people think that’s all a dyno is used for). It’s a quality control tool that allows you to make sure

Scratching the Surface: Coatings and Treatments for Engine Components

When it comes to preserving performance parts, it’s the ‘Icing on the Cake’ Various kinds of coatings and surface treatments can be applied to engine parts like icing on the cake to improve durability, enhance scuff resistance and lubrication, control heat, boost thermal efficiency and reduce friction. No single coating or surface treatment can

Engine Builder Shop Solutions: August 2013

Authors of Shop Solutions published in each issue of Engine Builder Magazine are awarded a prepaid $100 Visa gift card. Shop Solutions may also be submitted to [email protected]. A Better Way to Clean Oil Galleries I’ve always used the standard long handled nylon bristle brushes dipped in solvent to scrub the oil galleries in blocks,

3 Practical Tips for Assembling a Race Engine

Keeping clean, high quality oil in the engine is insurance against lubrication related problems – because what you can’t see, can hurt you. A human hair is about 80 microns wide, and the smallest particle size you can see with a naked eye is about 40 microns. That seems pretty small. Can something so small

Engine Builder Shop Solutions: July 2013

How to See Through Pistons for Clearance With the advent of longer stroke crankshafts, one inch plus lift camshafts, raised camshaft locations, lifter angles, bore spacing, etc., exact camshaft lobe and connecting rod clearance may not be able to be determined from looking up from the crankcase area of the block. To see through the

Cleaning Engine Blocks & Engine Cylinder Heads

Cleaning engine blocks and cylinder heads is just as important as the machining operations you will perform on the castings. You can’t do a thorough job of inspecting these parts if they are dirty, greasy or covered with paint or corrosion. Checking for cracks in cast iron heads and blocks requires a clean surface for

Engine Builder Shop Solutions: May 2013

Using Multi-Layer Steel (MLS) Head Gaskets As the name implies, MLS gaskets are constructed from 2 to 5 layers (depending upon the application) of heat treated stainless steel. Each layer is separated by a thin layer of a nitrile rubber coating. They have also been embossed in key areas to aid the sealing process, and to