Voodoo Aluminum Roller Rocker Arms

The product of extensive testing, these CAD designed and FEA optimized rockers were engineered specifically for high-performance street engines. Constructed from extruded aircraft quality aluminum and CNC machined to precise tolerances, the superfinished surface increases durability and sheds oil. They are lightweight yet strong enough to handle aggressive spring pressures and higher lift cams while

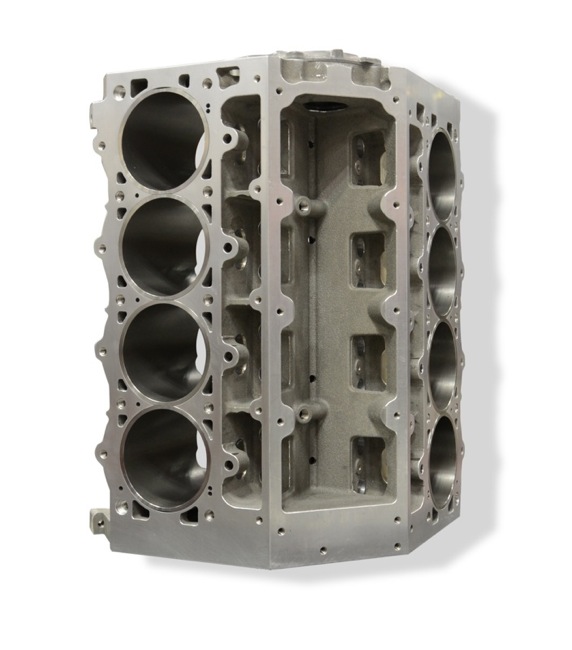

Dart Machinery Introduces Aluminum ‘LS Next’ Block

One year after revealing its remarkable cast iron LS Next engine block, Dart Machinery reduces its mass and announces an aluminum counterpart. Created from the finest casting materials and weighing 107 lbs, the LS Next was the first aftermarket block to comprehensively address high-performance troubles in the original equipment LS power unit. Laden with innovations,

New lightweight, aluminum oil pumps for 429-460 big-block Fords from Jon Kaase Racing Engines

These aluminum pumps are redesigned to eradicate fractures at mounting base and to improve idle and high rpm oil pressure Company: Jon Kaase Racing Engines, Inc. JonKaaseracingengines.com One of the main problems that beset tuners of big-block Ford engines is oil pump failure. The casting develops a fracture at the section change around its mountings, which

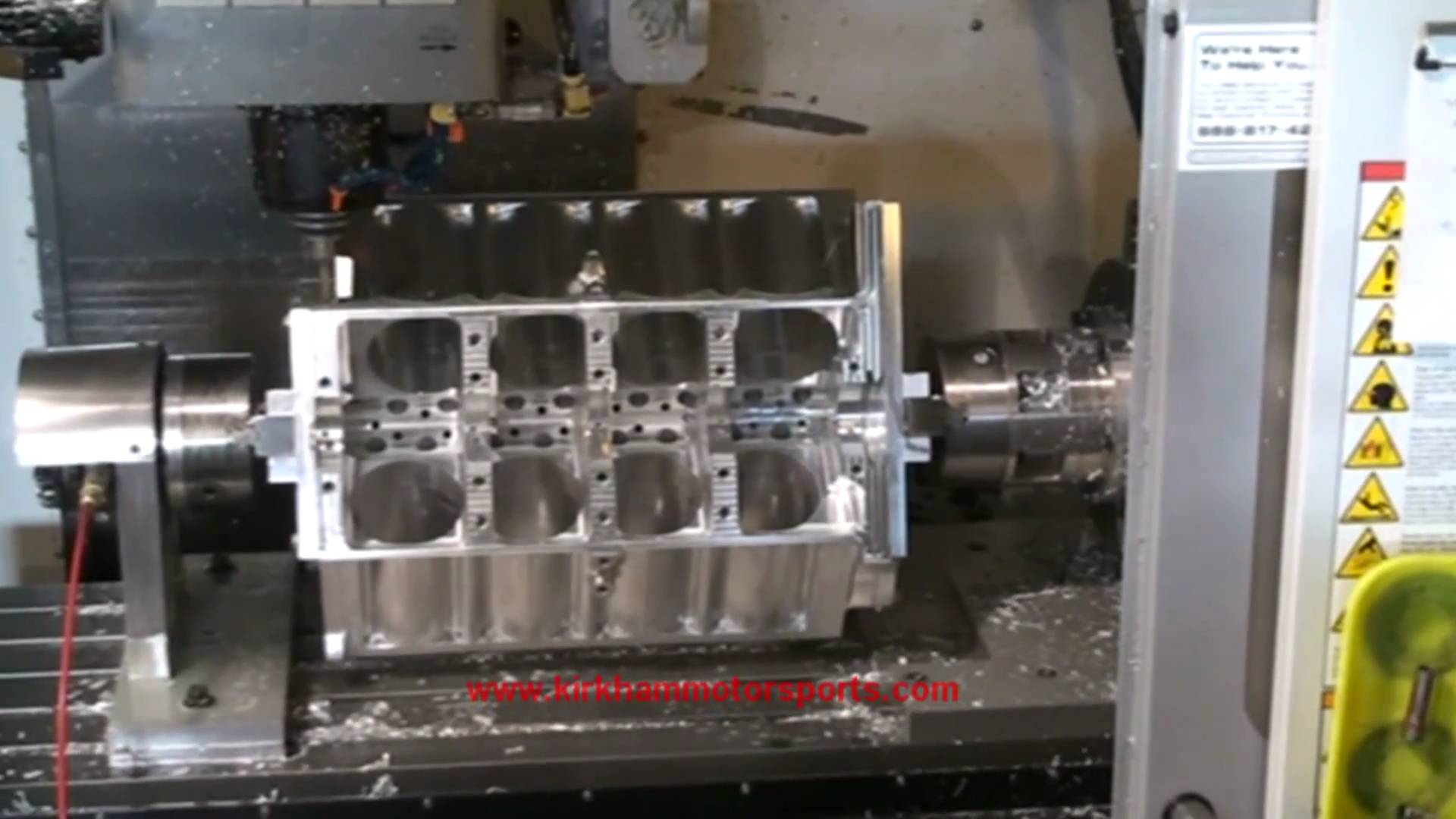

427 FE Engine Block Machining from Solid Aluminum

Kirkham Motorsports shows how it took a solid, 386-lbs. block of aluminum and machined it into a 427 FE engine block. Company: Kirkham Motorsports www.KirkhamMotorsports.com

Advantages of Using an Aluminum Flywheel

By Sam Logan Using aluminum sheds 10-15 lbs. from the rotating assembly of a conventional steel flywheel, but it is the effect the weight loss has on the moment of inertia – the measure of an object’s resistance to changes to its rotation – that contributes the real gains. The lower moment of inertia in

HPBG: Burnt Aluminum and Motor Oil

It’s a late-August Sunday in 1988 and I am staging up my Outlaw Pro Stocker for the final at the World Series of Drag Racing at Cordova, IL. I am driving my legendary ’79 Mercury Zephyr (Zeke) powered by the NOS assisted 1,600 hp “Monolith,” a 672-inch Kaase Boss Hemi Ford engine. I need

Caution When Press Fitting Aluminum Timing Gears

When timing gears are subjected to extreme temperatures, the aluminum gears do not return to their original dimensions after cooling. The result is a loose fit between the gears and camshaft. Under no circumstances should aluminum gears be heated with a torch. –Tech Tip courtesy of Hastings Manufacturing

Procedures for Checking Straightness on 1992-2003 Ford Aluminum Cylinder Heads

The surface quality (finish) of the cylinder head gasket surface ismachined to close tolerances that enable an effective sealing joint forthe MLS (multi-layered steel) gasket. To ensure all head gaskets sealproperly, be sure surfaces are clear of any gasket debris, RTV, oil,and coolant using Motorcraft Silicone Gasket Remover (ZC-30) andMotorcraft Metal Surface Prep (ZC-31). Use

AFR Adds Lifetime Warranty To Its Aluminum Cylinder Head Castings

Additionally, AFR announced, valves, guides, valve seats, valve springs, valve job, retainers, locks, studs, guide plates and valve seals will be covered under warranty for two years. AFR will repair at no charge and reimburse UPS ground freight and return UPS ground freight all warrantable defects in workmanship, materials or an undetermined cause (mystery failure).

TIG Welding Aluminum Heads

To survive in the current economic climate, you must look for opportunities to become more profitable and still maintain control of your profits. You must always look for ways to keep more of what you do “in-house” and keep as much of the revenue you generate in the business. Whenever you can control what goes

Manufacturer Tech Tip: How Do You Clean Your Aluminum Intake Manifold?

Edelbrock intake manifolds are manufactured from a sand cast process utilizing 808 aluminum alloy and have an as-cast wheel-a-brated finish. As-cast is defined as a raw aluminum finish without any protective coating. As-cast aluminum is porous and can absorb under-hood chemicals such as dirt, grease and fuel, resulting in discoloration, rust, or staining. All Edelbrock

Aluminum Cleaning & Machining

Steel may still be the big dog when it comes to the content of the world’s motor vehicles, but aluminum usage in cars and trucks continues to increase. Fueled by the desire to save weight, time and energy, aluminum is gaining ground with manufacturers of parts and components. How does the use of aluminum in

Cleaning Aluminum Engine Components

Engine rebuilding may be your career, but component cleaning may be one of your biggest jobs. Ever since the earliest days when engine builders had only a hot tank and a solvent sink to clean their parts they have been looking for better methods to get parts clean. Back then, most parts were cast iron

Getting Aluminum Clean: There’s More Than One Way

Cleaning aluminum creates special challenges for engine builders because of its corrosiveness and soft metal properties. There are several effective ways to clean this non-ferrous metal but there is no magic solution. You will more than likely have to combine several processes to get the kind of clean that you demand. The methods that will

Welding: Why weld aluminum?

As we are all aware, many of the components of the engines our industry remanufactures utilize this "mystery" metal. It first started with manifolds, then cylinder heads, timing covers, oil pans, lower main bearing girdles and finally blocks and all accessory mounting brackets. Don

Era Of Aluminum: Late-Model OHC Head Rebuilds

Over the last few years, manufacturers have abandoned cast iron heads in passenger cars and light trucks. Cast iron is heavy and the more radical, lighter, aluminum overhead cam (OHC) designs are the challenges and opportunities facing today

V-Process Aluminum

By using a new aluminum casting on the air intake manifold of our Roush Performance Products

Aluminum Cleaning: A Small Shop’s Perspective

By David and Jerry McLain Contributing Editors [email protected] Engine Builder magazine asked a specialist in rebuilding aluminum cylinder heads to detail his approach to cleaning. Many rebuilders today still struggle with cleaning aluminum properly, i.e., cleaned effectively with no damage to the head. Chemical, aqueous and heat cleaning are all methods used by engine builders

The Challenges of Rebuilding Late Model OHC Aluminum Heads

Take it apart. Put it together. Take it apart. Put it together. If taking apart and reassembling cylinder heads is eating up too much of your valuable shop time, keep reading. We have some tips on how to slash your disassembly/assembly labor costs, as well as other ways to streamline your OHC aluminum head rebuilding

TIG Welding Aluminum

The last thing you want to find when rebuilding a cylinder head is a crack. Yet cracks are common in many of today