Venturing Into GM Duramax Diesel Service

There are five generations of the Duramax engine. The best way to identify the generation is by the year, model and the RPO (regular production option) code. Back in the 1990s, GM wasn’t making too many waves in the diesel truck market. The 6.2L and 6.5L engines had been around for sometime, but they were no match

Addressing Ford Power Stroke Injector Misfire/Cackle

The #8 injector on the 7.3L engine is the farthest away from the oil pump, causing a filling problem, which may result in a misfire. Application: 1998-2003 7.3L Diesel E Series 1999-2003 7.3L Diesel Super Duty F Series 2000-’03 7.3L Diesel Excursion Problem: Some vehicles may experience a misfire or “cackle.” Cause: The injectors in the 7.3L diesel run

A Look Into the GM 3.1L Engine

Over the years, GM has saved a bundle on manufacturing the 3.1L engine by using the production line tooling it originally developed for the 2.8L V6. By simply changing the bore diameter, the displacement of the same engine block could now be increased for more power and torque. The General Motors 3.1L V6 engine enjoyed a long

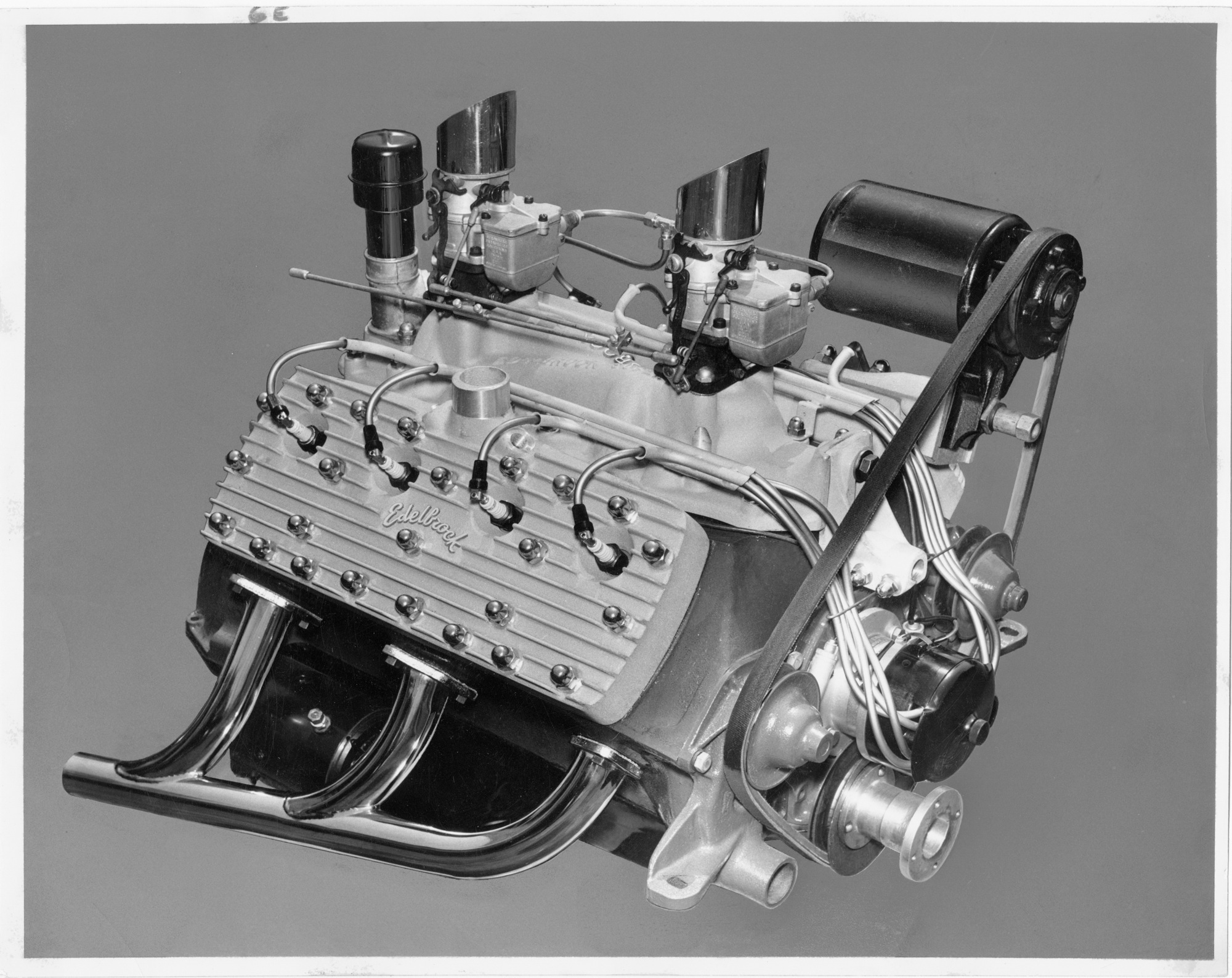

Gems From ’49 Bell Catalog

Long before the Internet, there was a man with a vision – and a catalog When Roy Richter wrote, “Here it is”on the inside cover of his 1949 Bell Auto Parts Catalog, he probably didn’t realize what he started. He said it was, “the most comprehensive and up-to-date catalog of racing equipment.” Bell Auto Parts

Solutions to Common Cylinder Honing Problems

Cylinder bore quality plays a huge role in reducing friction and blowby for improved engine performance and durability. Better bore geometry also contributes to better sealing and more usable power. Below are some solutions to the most common honing problems. PROBLEM: Hone is not cutting • If stones are loading, you need to apply more

Built for Auction

The criteria for selecting Engine Builder magazine’s inaugural “Performance Engine Builder of the Year” included much more than the ability to put together race-winning engines. Things like community involvement and the support of training and education were part of the mix. To be sure, our 2012 award winner, Ed Pink Racing Engines of Van Nuys,

Engine Builder Shop Solutions: June 2013

Removing Stubborn Dowel Pins Do you ever have solid dowel pins that are worn or tapered, and the slap hammer slips off no matter how tight you make it? Add a dab of valve lapping compound to the dowel pin. It works wonders. Most of the time the pin slaps right out. Jeffrey Myers MAR

Audi/Volkswagen 1.8L DOHC Gasoline Engine Valve Failure Caution

Reviews of these problems, which are leading to breakage of the valves, and in some cases catastrophic failures, are related to problems not with the valves themselves but the method of cylinder head overhaul and re?claimed mating components. Many of the breakages examined are occurring very shortly after a rebuild and appear to mainly be

Ford 7.3L Power Stroke Diesel Injector Removal and Installation

The following special tools are needed for this procedure: Removing the injectors: 1. Remove the valve cover. 2. Drain

A New ‘Finish’ in Honing

For years, engine builders have been honing cylinders with a coarse stone followed by a finishing stone. Then ring materials changed, requiring an additional very fine finishing stone to follow. Now current technology demands an added step to create an even cleaner, burr-free finish. However, even with these conventional honing techniques, peaks of folded and

Performance Gaskets & Surface Finishes

The most critical engine gaskets are the head gaskets since they have to withstand the heat and pressure of combustion. And unless the engine is a drag motor with a solid billet or filled block, the head gaskets also have to keep coolant out of the cylinders. Many performance engines are capable of making

Valve Seats & Guides

Most engine builders worth their salt know that with the components and technology available today, it’s not that difficult of a task to make horsepower. With the availability of so many performance parts – whether it’s from the OEM or the aftermarket – engine builders can pull from vast resources to achieve a balance between

Valvetrain

Selecting the right components to make a rock-solid valvetrain is key to assembling an engine that will last – and win. The pushrods, rockers and valve springs must be able to handle all of the stresses of the camshaft rotating with high spring pressures and with huge lift. Weakness in any part of the system

Green Strategies: Cleaning Techniques & Equipment

It may seem that there’s nothing natural about cleaning an engine. Even after the couple of hours of cleaning time, the engine might be cleaner than the tech working on it – but the engine still needs cleaned (and so does the cleaning crew from time to time). We are long from the days of

Selecting the Correct Filter to Prevent Lean-Out and Pump Failure

Aeromotive recommends the filtration media to be used on the inlet side of a fuelpump be no smaller than 100-micron and must have an element surfacearea of 60 square inches or more. Any filter element not meeting thesecriteria may fail to flow the full volume of the pump being used,resulting in cavitation at the pump

Engine Builder Shop Solutions: March 2013

Safe Valve Spring Break-In Most engine builders are well aware of the fact that high performance valve springs should be compressed to coil bind through several cycles before being installed. The problem with this procedure is that it can be time consuming, costly and even dangerous. It is time consuming if each spring is compressed

Proper Installation of Elastomer Cylinder Head Cover Gaskets

The advantages are clear: weight reduction, a high degree of constructional freedom in design, integratability of additional components such as the "Multitwister" oil separator, decoupling of components and therefore reduction in noise emissions, etc. An adaptable rubber gasket requiring only little line pressure ensures reliable sealing. Regarding warping and bolt spacing, however, physical limits are

Top Reasons and Causes for Camshaft Failure

Of all the damaged cams that Crane Cams has checked over the years, it says more than 99.99 percent have been manufactured correctly. Some people have the misconception that it is common for a cast iron flat tappet cam to occasionally have a soft lobe. Crane says they have yet to see a cast iron

Custom Crankshafts and Connecting Rods

As an engine builder, you get to decide what parts go into the engines you build. If you’re rebuilding a stock engine to stock specifications, you’re probably going to use a reconditioned stock crankshaft and connecting rods to keep costs down. There’s no reason to upgrade these parts because they should be adequate for the

Matching Pistons And Rings

Whether you are rebuilding a high-mileage engine or building a fresh engine from scratch, matching the pistons and rings to each other and the application is essential for a successful outcome. Rings are a wear component that are usually replaced during a rebuild. The pistons may be reused if they are not damaged, cracked or