Picking a Racing Oil

How do racing oils differ from everyday motor oils? You might think all racing oils are synthetics, but they are not. Some use conventional mineral base oils, others use PAO and ester synthetics, and some are a blend of conventional and synthetic oils. It doesn’t really matter which way a racing oil is created as long as it meets the criteria for which it was designed.

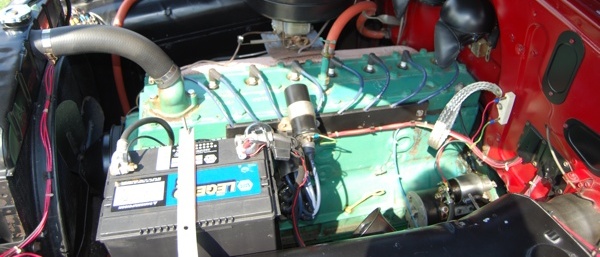

The 392 Magnum V8 Build is a Wrap

The 392 Magnum engine build is a wrap. We’ve done all we can and now it’s going to power someone’s muscle car, hot rod or truck. When all is said-and-done the only things original in this 318 motor are a fully machined block, the cam thrust plate, the fuel pump eccentric and the bolt and washer holding on the harmonic balancer. Everything else is brand new.

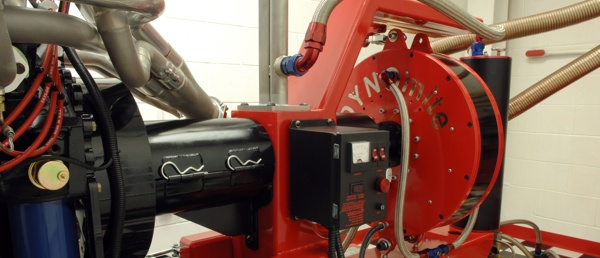

Consider a Dyno/Flow Bench for Your Shop

Any engine builder that is doing performance work or high volume engine building can benefit from owning an engine dynamometer. A dyno is not just a tool for plotting horsepower and torque curves. It’s also a tuning tool for plotting and adjusting fuel mixture and ignition calibration, a quality control tool to assure proper engine break-in, valvetrain adjustments and to verify compression, ring seating and gasket sealing. It can also be used as a performance and/or durability research tool.

Selecting Pushrods, Rockers and Springs for Your Build

Everybody knows you need the right combination of valvetrain components to maximize an engine’s power potential. The trick is figuring out which components are the “right” ones for a given application. A high revving engine with an aggressive cam needs lightweight rocker arms and stiffer valve springs to keep up with the cam.

Shop Solutions – December 2014

In our shop, we don’t have a dyno or engine test stand. We work on a variety of engines from Chevys to Internationals to Continentals, so no engine start stand would suit everything we do. In an effort to find oil leaks, we have started to “smoke” our engines.

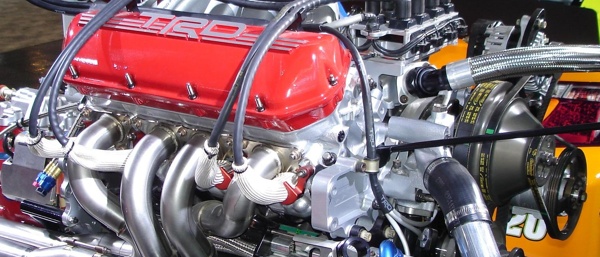

Sticker Shock – The 392 Magnum Gets Ready for Auction

As you can see in the pictures, we’ve reached a point where we can say the engine is built and ready to install. Or in this case ready to dyno and auction off. We certainly would not have been able to produce such a cool piece without the help of our contributors and Grawmondbecks Competition Engines. The 392 V8 Magnum engine is currently being auctioned off on eBay Motors. The auction ends Dec. 21.

Five Points to Ponder Prior to PRI

Being an FE Ford fan, and having raced them, and still owning several, “Animal” Jim enjoyed Engine Builder’s article about FE Fords in the April Issue. Jim has been in love with FE’s since his brand new ’63 R code he had when he was 22. In this article he share’s five points prior to the 2014 PRI show.

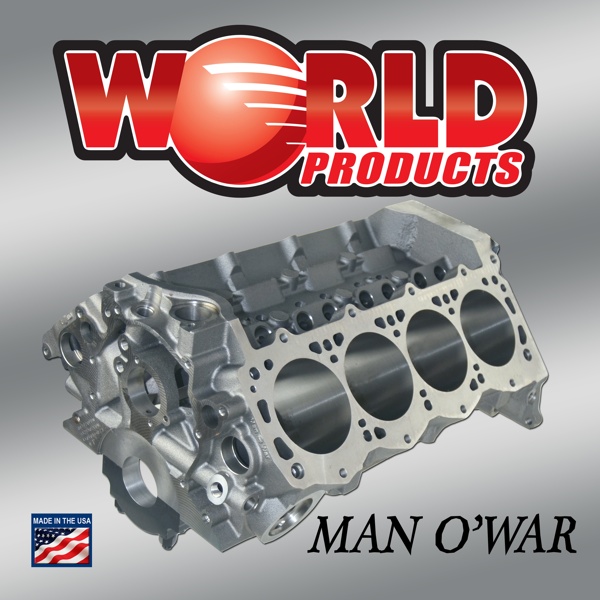

World Products Windsor Style Small Block

World Products has revised its small block Ford castings to make the blocks even stronger and easier to build. Available with a 302 style 8.200″ deck height or a Windsor style 9.500″ deck height, the Man O’War blocks are packed with performance enhancing features such as higher grade iron alloy for even greater strength. See World Products at PRI in booth #1343.

Performance Oiling Systems

The basic purpose of an oiling system is to provide lubrication for the engine. It doesn’t matter if the system is a wet sump with an internal oil pump mounted in the crankcase or front cover, or a dry sump system with an external multi-stage pump. The engine doesn’t know the difference as far as where the oil comes from – as long as the flow keeps coming at all RPMs and under all operating conditions.

Pontiac’s Straight 8s

The Pontiac L-head straight eight was used in production cars for 21 years between 1933 and 1954. This classic engine was advertised as a powerplant that could run 100,000 miles without a major overhaul.

Modified Ford Model Bs

It was known as the Model B engine and was produced for only four years beginning in 1932. Sporting only four cylinders, it was basically an upgrade of the earlier Model A powerplant. The “B” engine sported an impressive 200 cubic inches of displacement. Its compression ratio was a super-low 4.9-1. The paltry 50 horses it produced came at about 2,200 RPMs. The engine certainly didn’t appear likely to be a candidate for upgrading, but that wouldn’t be the case.

Parts Happen

We chose to expand on the idea of taking the engine under the hood of your customer’s car, and modifying it rather than searching out a more desirable muscle car engine. Now, with the money you’d save by not having to purchase another expensive desirable core motor, invest that money into a stroker crankshaft and a set of matching pistons to build a bigger cubic inch engine that would have more power than the old factory muscle car engine and greater dependability from the new upgraded parts.

Company Innovations

While technology in general was the primary answer to what innovations helped grow the industry over the past 50 years, when asked about innovations within their own companies that have helped the industry, the answers were more specific to certain engine parts. “Over the years a number of Sunnen innovations have been standards of the

Melling / Dura-Bond

The Melling story began in 1946 in Jackson, MI, when George Melling Sr. and his son Ben started production of aftermarket oil pumps. In 1952 they introduced the first high-volume oil pump, which revolutionized the automotive aftermarket industry for oil pumps. In 1975, Harry Melling took over the company as the third generation president. Harry’s

Internal Affairs – Diesel Crankshafts and Rods

Despite having similar appearances, a diesel crankshaft has some primary differences from its gasoline counterparts. A gasoline engine uses a spark to ignite the fuel. A diesel engine, operating at a much higher compression ratio, uses the heat produced by compression to ignite the fuel. Diesel engines typically have a longer stroke than the bore diameter, so to handle this load, diesel crankshafts are much larger physically.

The Ford ‘FE’ – Rebuilding An American Iron Icon

Ford produced the FE series engines for almost 20 years and in this time period, this series of engine gained quite a following. After researching the FE, I was intrigued about its internal workings. I had always heard about and seen some of the more popular FE engines such as the 390, 427 and 428 but never had a chance to dive into one – until now.

Must Have Shop Tools & Measuring Equipment

You can’t do quality work in an automotive machine shop if you don’t have the right tools and measuring equipment. “Must have” tools and equipment include those that are necessary for engine disassembly, for inspecting and measuring engine components, and for engine assembly.

Ford’s Power Stroke Powerplants

The biggest question heard from customers is, “Why did Ford replace the 7.3L with the 6.0L?” There are good reasons as to why the 7.3L Power Stroke had to be removed from service and these reasons brought about many changes in the Power Stroke platform.

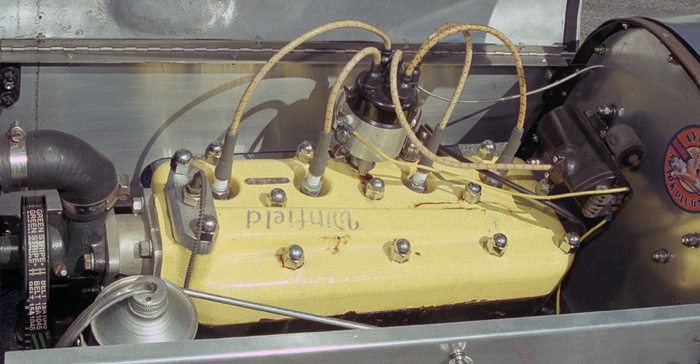

British Invasion – All the King’s Horsepower

Interest in British sports cars grew in the U.S. after World War II, when soldiers returning from England brought MG TCs home with them. Soon other sports cars came from “across the pond.”

September 2014 Shop Solutions

One of the most important factors in engine bearing design is a proper fit between the bearing and housing. Except for thrust washers, nearly all bearings are an interference fit. This means the bearing is slightly larger than the hole it fits into. In bushings, we refer to this as “Press Fit.”