Choosing the Correct Camshaft for the Build

Choosing a particular type of camshaft for an engine build is an important decision that has to be made before any other parts are ordered or machined. Choosing a cam requires answering some basic questions, the most important of which is the engine application itself.

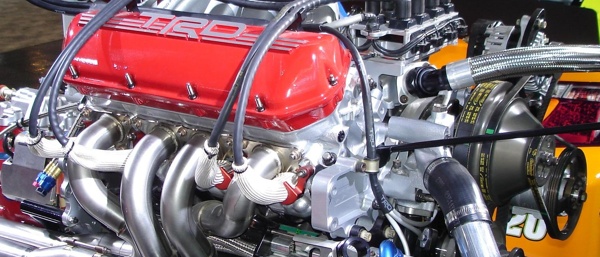

Performance Oiling Systems

The basic purpose of an oiling system is to provide lubrication for the engine. It doesn’t matter if the system is a wet sump with an internal oil pump mounted in the crankcase or front cover, or a dry sump system with an external multi-stage pump. The engine doesn’t know the difference as far as where the oil comes from – as long as the flow keeps coming at all RPMs and under all operating conditions.

Upgrading Valve and Seat Equipment

If high quality head work is a cornerstone of your business, you should review your current situation to see if an equipment upgrade could improve not only the quality but also the quantity of your work.

Holley EFI Digital Dash

The Holley EFI Digital Dash features plug-and-play compatibility with all Holley EFI systems via a CANbus connection. The compact unit features a 7″ low glare, high brightness, high contrast, full color touch screen for easy viewing, even in full sunlight. The screen provides nearly limitless customization.

Going Hohl School

During the 1950s and ‘60s, building and tuning a performance race engine was a different world from today. It was definitely more of a hands-on situation where the feel, sound and smell of an engine were important tools of early engine builders.

Pontiac’s Straight 8s

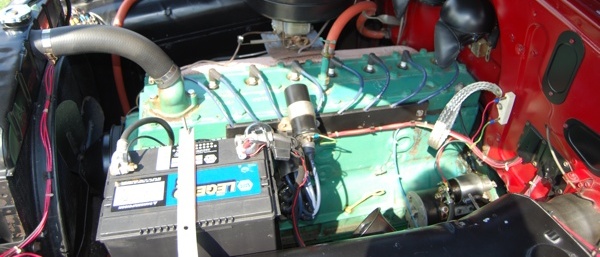

The Pontiac L-head straight eight was used in production cars for 21 years between 1933 and 1954. This classic engine was advertised as a powerplant that could run 100,000 miles without a major overhaul.

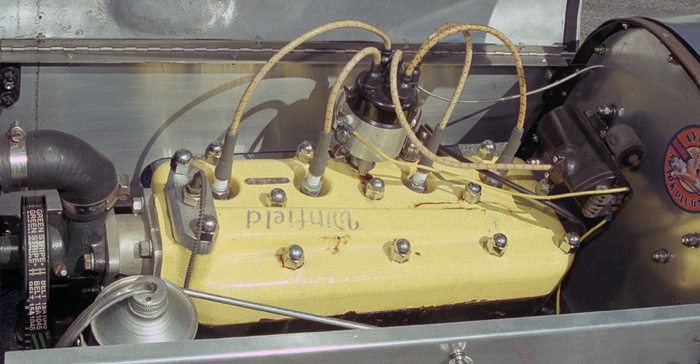

Modified Ford Model Bs

It was known as the Model B engine and was produced for only four years beginning in 1932. Sporting only four cylinders, it was basically an upgrade of the earlier Model A powerplant. The “B” engine sported an impressive 200 cubic inches of displacement. Its compression ratio was a super-low 4.9-1. The paltry 50 horses it produced came at about 2,200 RPMs. The engine certainly didn’t appear likely to be a candidate for upgrading, but that wouldn’t be the case.

Greetings From Bonneville

This year an opportunity came to go to a gathering of speed freaks drawn together from around the world. An event that I’ve now learned is on most “Motorhead’s” bucket lists, and was put forth as the background for a great movie that hit limited screens in 2005 and is recorded on DVD in many of our video libraries. The movie was “The World’s Fastest Indian,” and the event is simply called “Bonneville.”

MSD Atomic AirForce Intake Manifold for LT1 and LS Platform

If you’re looking to bolt-on power and torque, the new Atomic AirForce intake manifold from MSD is the answer! This all-new polymer intake will increase the performance of stock and modified GM LS engine platforms and the new LT1 engine. MSD started designing the AirForce by addressing the performance shortcomings of the OE manifolds.

BMW Picks Shell as Global Oil Supplier of Choice

Shell has announced that it has been chosen by BMW AG as the only recommended supplier for aftermarket engine oils for the nearly all of BMW’s brands including MINI and BMW Motorrad. Shell premium engine and motorcycle oils will be supplied for BMW service-fills around the world.

The Equipment and Tool Institute Names Greg Potter Executive Manager

The Equipment and Tool Institute has announced that its Board of Directors named Greg Potter as the organization’s next Executive Manager effective November 1, 2014. Potter has been actively involved in ETI since 1985, holding many positions within the organization including three terms on the Board of Directors, President of the ETI Board of Directors from 2004 – 2006, Technical Manager from 1994 -1997, Scan Tool Group Chairman from 2010 to present, as well as serving on various Committees including the Marketing and Program Committees.

The Best-Kept Secret to Generating More Referrals

The reality is that regardless of how well you treat customers, and no matter how pleased they are with your service, when your customers walk out of your shop they’ll step back into their busy lives, and they will forget about you. They will think of you again only when they have a need for your services, or when a friend engages them in a conversation about auto repair. Here’s an easy-to-use procedure that will turn your customers into salespeople, and fill up your engine shop with customers who are presold on you.

Mercedes Formula 1 Turbocharger Technology

After a long stay in the naturally aspirated arena, Formula 1 has returned to turbocharged power, and the units used on the 1.6 liter six cylinder engine are among the most advanced in the world. Despite the fact that this year’s formula only employs one turbo, rather than the conventional two for six cylinder engines, the difference is made up in innovation. Formula 1 has concocted their own novel way to combat turbo lag, using their Energy Recovery System.

Parts Happen

We chose to expand on the idea of taking the engine under the hood of your customer’s car, and modifying it rather than searching out a more desirable muscle car engine. Now, with the money you’d save by not having to purchase another expensive desirable core motor, invest that money into a stroker crankshaft and a set of matching pistons to build a bigger cubic inch engine that would have more power than the old factory muscle car engine and greater dependability from the new upgraded parts.

When to Upgrade a Performance Head Gasket

A rule of thumb for performance engine building is that if you are doubling an engine’s power output, or are going much over 550 to 600 hp, you should upgrade to some type of aftermarket performance gaskets. Upgrades usually require no additional modifications. You just swap a performance MLS gasket for the stock head gasket.

Company Innovations

While technology in general was the primary answer to what innovations helped grow the industry over the past 50 years, when asked about innovations within their own companies that have helped the industry, the answers were more specific to certain engine parts. “Over the years a number of Sunnen innovations have been standards of the

The Rebuilding Industry’s Key Innovations

When asked about what innovations in the past five decades that have been key to the industry’s growth and success, there was a trend in favor of an all-encompassing answer – technology. While technology is the umbrella answer, there are numerous aspects of technology and its advancements that have made the industry what it is

Packard Industries

Packard Industries was built in 1978 on the idea of covering the day-to-day costs of business with wholesale division. Our main objective was to supply the various specialist retailers in the industry. At first we did not actually provide engine parts. We started out with a small suspension line, water pumps and fuel pumps. As

RMC

Rogers Machine Company (RMC) was founded in 1957 by Al Rogers. Mr. Rogers was operating a successful group of machine shops in Michigan and saw the need for a source of quality and affordable engine rebuilding machinery. He started in Denmark with AMC crankshaft grinding, align boring and resurfacing machines and then moved on to

Elgin Industries

Elgin Industries is celebrating its 95th anniversary this year, and from our founding in 1919 through today we have been dedicated to manufacturing world-class products for the engine rebuilding industry. Our founder, Martin Skok, was an automotive technician at an Elgin, Illinois-based vehicle dealership when he became frustrated with a serious shortage of high-quality replacement