COMP Cams HRT Turbo & Supercharger Camshafts for Dodge Gen III HEMI Engines

The Gen III HEMI market is rapidly expanding and the HRT Camshaft Series uses the newest and most advanced lobe designs from COMP Cams in order to produce some of the highest average power and torque increases available.

COMP Cams LST & HRT Performance Camshaft Packages

LST & HRT Performance Camshaft Packages take the guesswork out of choosing the best valvetrain upgrade for your specific engine and desired performance. The Low Shock Technology behind these performance packages features lobe profiles designed to maximize horsepower, while improving stability at higher rpm. These profiles are also easier on the valve springs, enhancing durability and reducing load

Engine Pro Diesel Performance Engine Parts

Engine Pro has introduced its first line of diesel performance engine parts with the introduction of its camshafts and valves for Ford Powerstroke, GM Duramax and Dodge Cummins Engines.

Camshaft Selection

“What camshaft should I use?” How many times have you been asked or heard that question uttered? Why is it so difficult to choose the “correct” camshaft for an engine build? What separates one camshaft design from the other? After all, isn’t it true that a camshaft opens and closes valves? Simple, right? Well let’s

Round and Round – Valve Timing Events and the Order of Importance

If you’ll recall, in the January issue, we got into the nitty gritty details of what makes a camshaft the “right” camshaft. In this issue, we’ll continue the education. Cam class is back in session! Remember the camshaft makes one complete revolution (360°) while the crankshaft rotates twice (720°) for a complete engine cycle. Camshaft

Camshaft Class is Back in Session

A theory prevails in which a cam lobe that opens to maximum lift and closes instantaneously is quintessential for maximum power and torque operation. Two problems exist with this premise. First, it’s highly impractical due to current technology. Second, this theory discounts a fundamental dilemma that air has momentum, and this must be utilized to achieve

Choosing the Correct Camshaft – Bangin’ on the Bumpstick

There are numerous aspects involved in designing an engine combination. Displacement, compression, airflow, etc., and it is the camshaft’s job to ensure that all of these work together properly to achieve optimum performance. That’s why the cam is often referred to as the “brain” of the engine.

Camshaft Selection and Design

Choosing the right cam from all of the possibilities that are out there can make a significant difference in how well an engine performs. It’s all about balance and correctly matching the cam with the cylinder heads, compression ratio, intake and exhaust systems, and RPM range where you want the engine to produce the most torque and horsepower.

Choosing the Right Camshaft for a Performance Engine

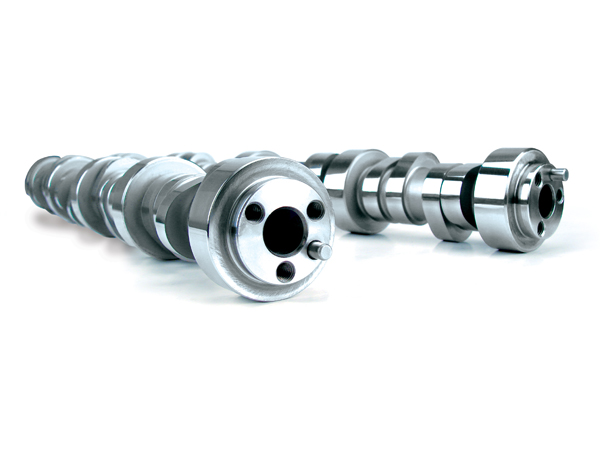

A camshaft is nothing more than a cast iron or steel shaft with a series of lobes strategically placed along its length. Each lobe opens and closes a valve by moving a lifter, pushrod and rocker arm, or in the case of an overhead cam engine by moving a cam follower or direct valve action. However, choosing the right camshaft is not only the cornerstone of building a performance engine, but also its centerpiece.

Blake’s Remanufacturing’s 40-Year History and Future

In today’s volatile business environment, many companies don’t last long enough to see many milestone anniversaries, let alone make it long enough to see the third generation of leadership. However, despite the odds of the business world being against them, Blake’s Remanufacturing in Denver reached its 40th anniversary milestone in 2013. The company remanufactures crankshafts,

3M Cubitron II Vitrified Wheels

With the new addition of 3M Cubitron II Vitrified Wheels, 3M Abrasive Systems can give engine manufacturers up to three times the wheel life of other conventional wheels for applications including gear grinding, camshaft and crankshaft grinding, cylindrical grinding and centerless grinding. The key to the strength and performance of Cubitron II products is in 3M’s patented

COMP Cam LSR Series Hydraulic Roller Camshafts

The LSR Series is a lineup of hydraulic roller camshafts featuring COMP Cams’ most modern lobe designs for popular GM LS engines. Designed specifically for radical street performance and all-out race applications, these aggressive-profile cams take advantage of today’s newer, better-flowing aftermarket cylinder heads. The LSR Camshafts feature higher exhaust duration and overall lift, making them