Engine Sealing Using Hoops and Receiver Grooves

When building engines beyond 2,000 horsepower, cylinder pressures can get intense, making the head gasket’s job of sealing the engine a tough one. To create better engine seal in these high-horsepower applications, engine builders such as Steve Morris of Steve Morris Engines, use hoops. In this Steve Tech, Steve walks you through how today’s hoops

Buying Machining Equipment

With the cost of some of these pieces of equipment equaling that of a house, it is crucial that engine builders and machine shop owners understand what options are available to them when looking to purchase new or used equipment.

Hone in on Honing

The key to honing is to get the rings to seal against the cylinder wall by making just enough valley depth.

CNC Machines Keep the $pindle Moving

CNC block machining centers and CNC cylinder hones are some of the most popular machines today. These machines can increase productivity in the shop significantly.

Romi GL Series Turning Center

The new machines are available in four models with maximum cutting diameters.

CNC Machine Centers

One curious fact that caught our eye in the latest Machine Shop Market Profile, published in June, was that 41% of readers – engine builders – don’t use a computer to run their shop. This begs the question: if you don’t use a computer for basic bookkeeping, are you using one for machining?

Black Friday Provides Machine Shops and Manufacturers Opportunity

During the Black Friday sales week, a Florida-based used CNC machine dealer is making sure that American machine shop owners and smaller manufacturers benefit as well. From 8 a.m. Tuesday, Nov. 20 through 8 p.m. Friday, Nov. 23, CNCMachines.net will host a unique virtual sale on select used CNC machines from Haas, Mazak, Samsung, Tsugami and more.

Sourcing CNC Solutions – Making the decision for CNC may be scary, profitable

CNC machining equipment can be a double-edged sword to many engine builders that promises flexibility and profitability, yet often requires a significant upfront investment. As with any piece of equipment, there’s no “one size fits all” solution, and three top engine builders explain how they overcame the fear of financing and failure to find success

Making the Plunge into CNC

Computer Numeric Controlled (CNC) machines are changing the way many machine shops build engines. CNC provides a level of automation, sophistication and accuracy that manually operated machines can’t match. CNC also has the potential to dramatically increase productivity and profitability.

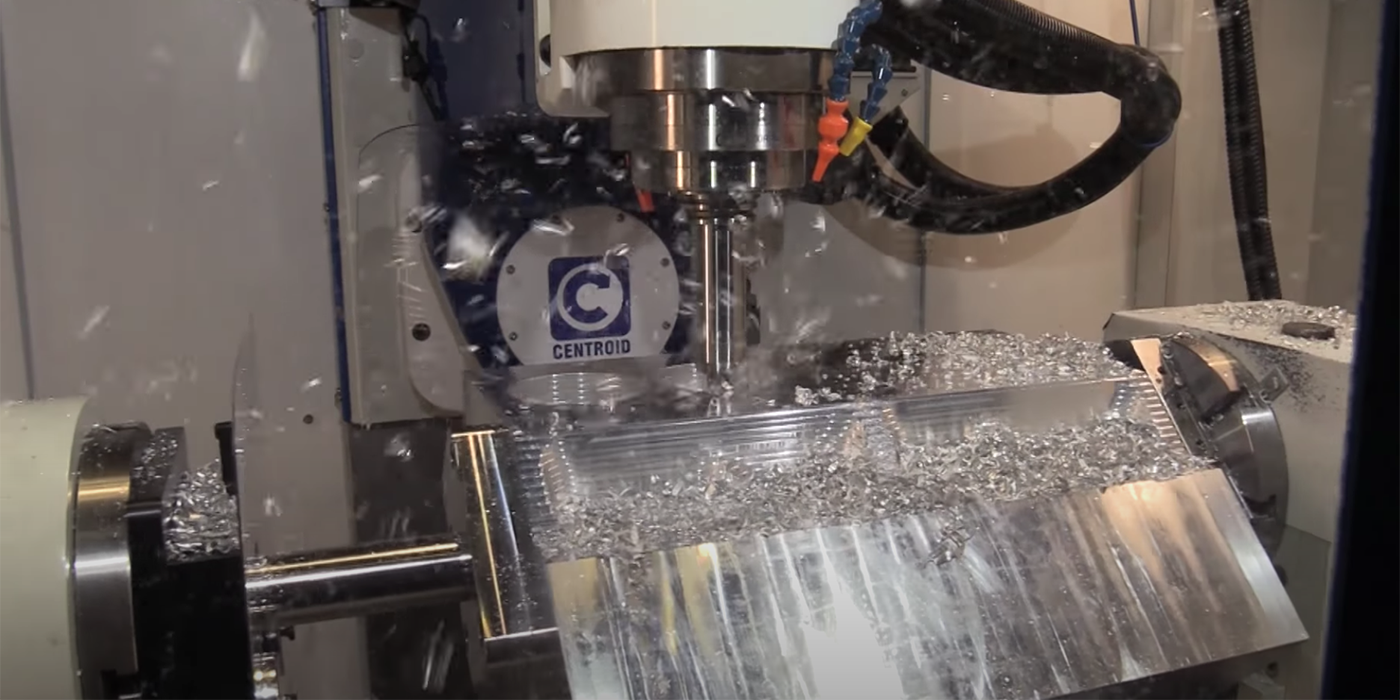

Centroid CNC Machine Tools at PRI

Centroid demonstrates its CNC machine line at the 2014 PRI Show in Indianapolis.

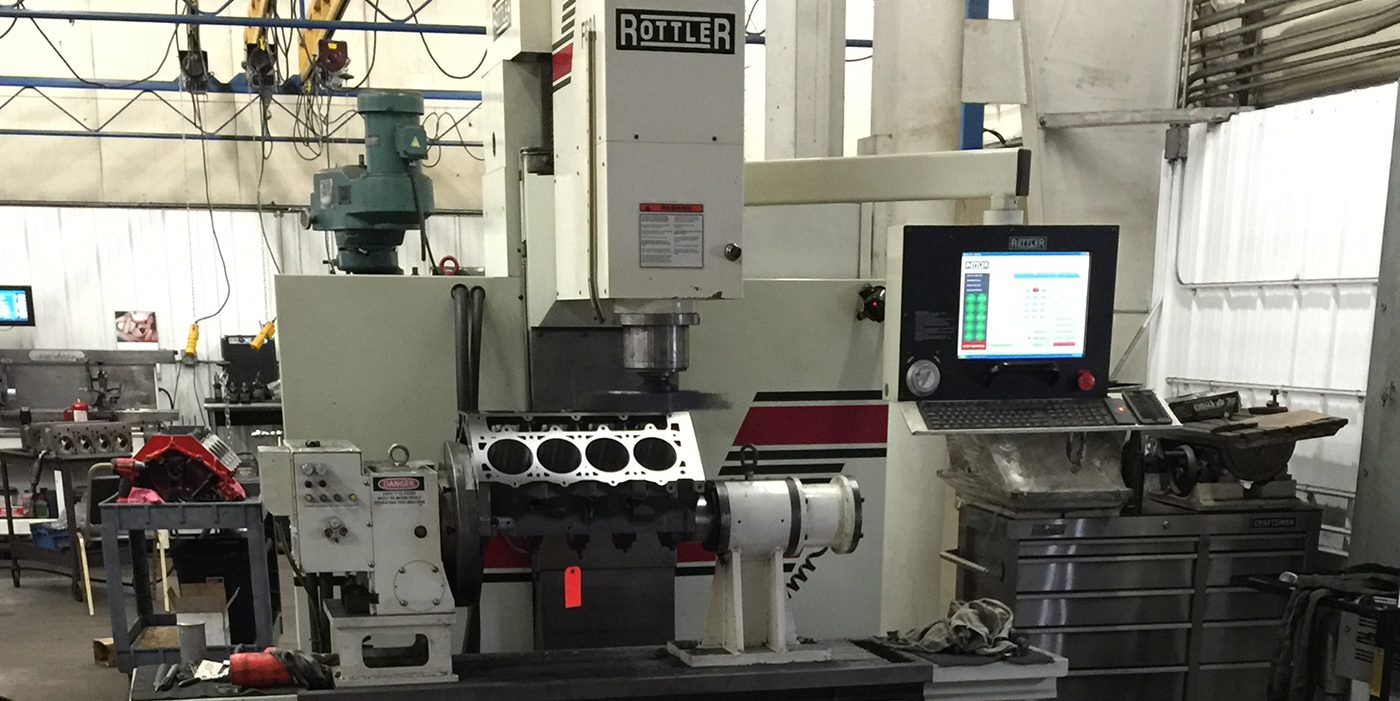

Roush Yates Engines Installs its Third Rottler CNC Machine

Roush Yates continues to push the boundaries of innovation in its manufacturing process by partnering with Rottler Manufacturing. Roush Yates is now partnering with Rottler and utilizing two H75A honing machines for block honing and a F69A for block machining.