Designing a Better LS Engine

After a customer wanted a Steve Morris Engines’ SMX in an LS version, Steve saw the upside and potential in the market, and a challenge to build a better LS.

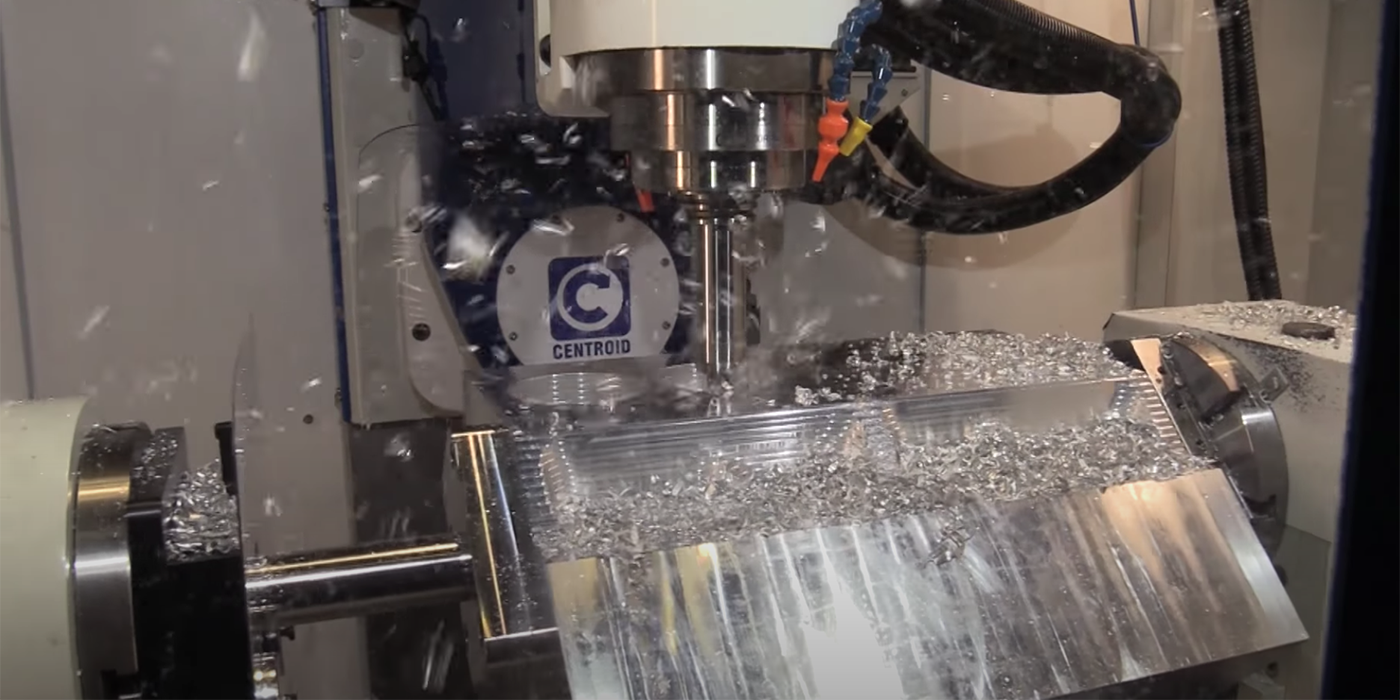

The CNC Landscape Continues to Grow Inside Engine Shops

Several manufacturers named automation as one of the biggest continuing trends surrounding CNC equipment these days, and it’s clearly a key contributor to a CNC machine’s ability to do more without human interference.

Inside Pro Motor Engines in Mooresville, NC

During our recent trip to Charlotte and Mooresville, NC, we got the opportunity to tour Pro Motor Engines with owner Dennis Borem. This engine machine shop has a rich 40-year history of building engines for all three top NASCAR Series as well as ARCA, SCCA and NHRA. PME focuses on high performance engine building and

Rottler Report with Chris Straub of Straub Technologies

Chris Straub is the owner of Straub Technologies, an engine machine shop located in Piney Flats, TN. Their relationship with industry legends have produced unique business alliances that allow the business to offer its customers the best products, services, tech support, and prices – from custom-machined parts to volume deals on national brands and closeout

Rottler Report with Steve Morris of Steve Morris Engines

Steve Morris is the owner of Steve Morris Engines, an engine machine shop located in Muskegon, MI. They recently purchased a new Rottler Manufacturing H85AX machining center. With in-house prototype development and CNC machining capabilities, Steve Morris Engines builds close to 100 exclusive, full-custom engines each year. They also have the capability to dyno tune

Rottler’s EM45 CNC Machine

The EM45 features universal CNC technology designed for all engine shops and allows you to probe, surface and bore on the same machine.

CNC Update: Features and Automation

Precision is key when it comes to automotive parts; the complex designs of connecting rods, pistons and rings, blocks, cylinder heads, and other parts require super tight tolerances that are getting more and more difficult to be met by hand or with other machining processes outside of CNC.

Comec ACF200 CNC Boring Mill

Comec’s ACF200 CNC cylinder boring/resurfacing machine introduces highly innovative solutions, making this machine faster and more practical to use.

Industry Veterans Form MEC CNC Machines

Anthony and Elle Usher, veterans of the engine machining industry, have formed MEC CNC Machines based in California. “Our goal is to bring precision engine machining equipment to a broad range of customers servicing internal combustion engines,” says Anthony Usher. “Our clients rely on versatile equipment for manufacturing, modifying and rebuilding engines and related components.

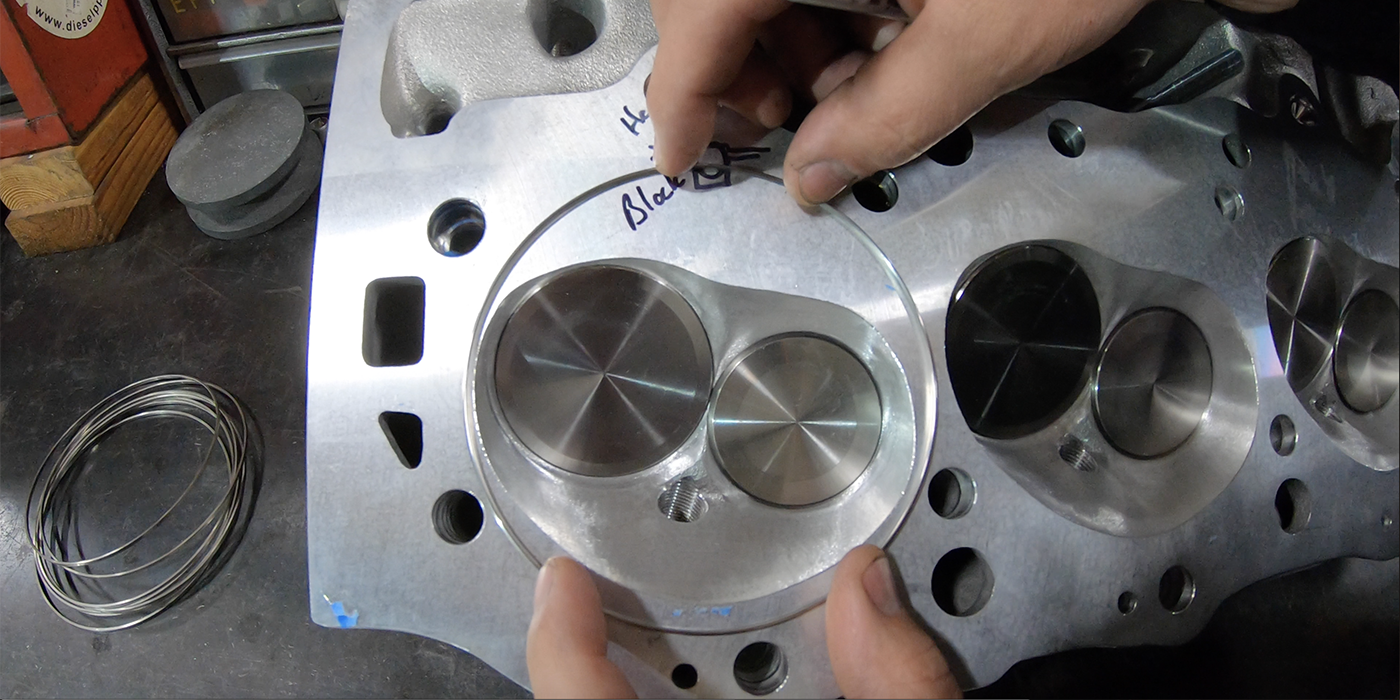

Hoops for High Horsepower

The hoop offers better sealing against exhaust gases because rather than the pressure trying to escape from a flat-on-flat surface, the hoop creates a lock between the head and the block to better seal the engine.

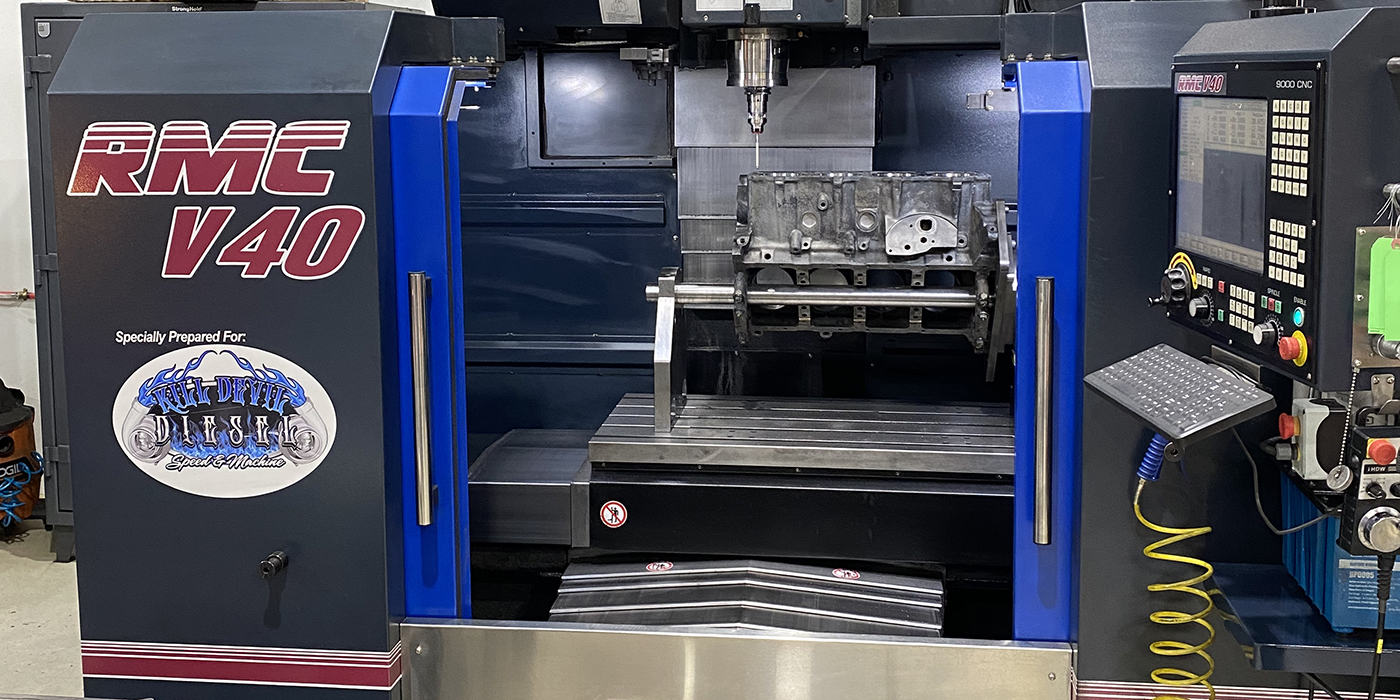

CNC Machines Keep the $pindle Moving

CNC block machining centers and CNC cylinder hones are some of the most popular machines today. These machines can increase productivity in the shop significantly.

Cylinder Head Porting; Turning Air Into Power

In general, the most critical areas when porting a cylinder head are those which pass the most air at the highest speed and for the longest duration.