MEYLE Crankshaft Sealing Flanges

Sealing flange modules are important to ensure effective sealing at the engine crankshaft. They are also used to capture the engine speed and crankshaft position, and to determine both the injection and the ignition point controlled by the engine timing unit.

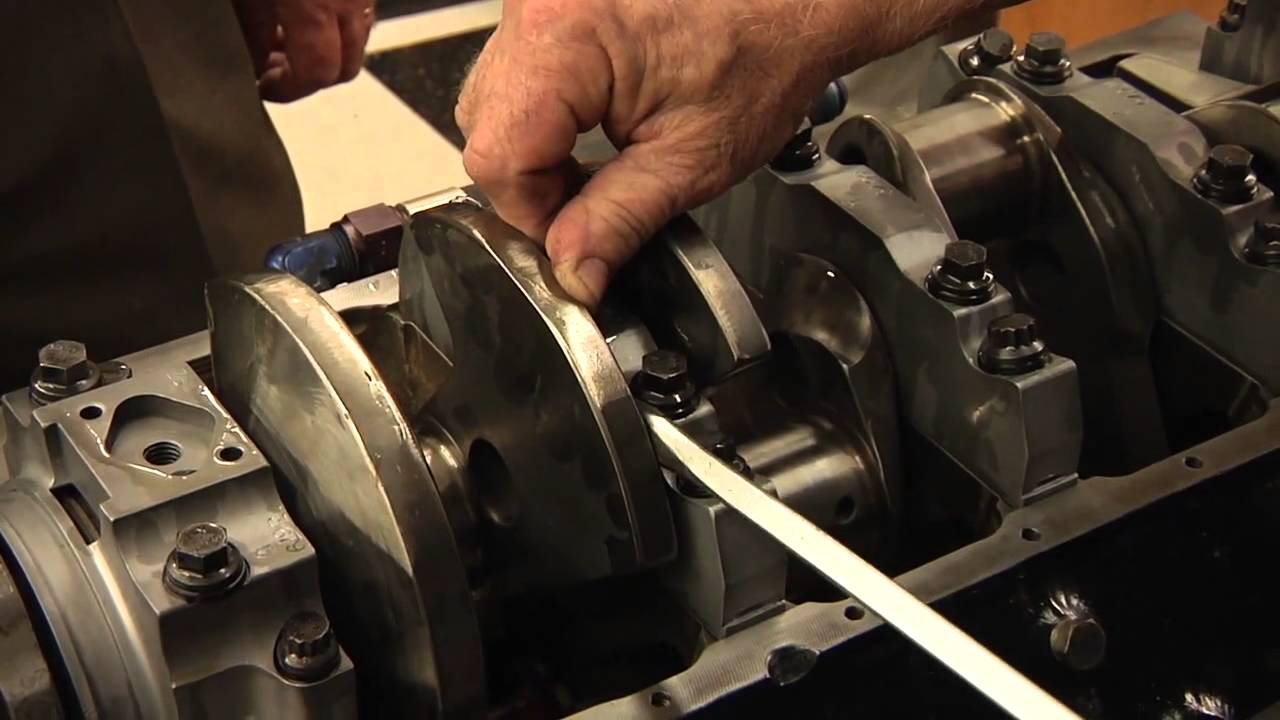

Understanding Today’s Bearing Clearance Recipe

What’s needed to keep the rotating assembly rotating? It’s a recipe that includes three key ingredients: the bearing, the crankshaft and the oil. But understanding the part each plays as part of this recipe is what’s needed to keep your engines’ bearings from failing.

Timing Belt Tips on Accord 2.2L and 2.3L Engines

These tips outline the belt replacement for the popular 2.2- and 2.3-liter Accord engines. The other Honda engines are similar, but don’t require the balance belt. They shouldn’t present any challenge to the experienced tech, but there are some things to keep in mind as you tackle these jobs. The 3.0-liter V6 models use a hydraulic

Maintaining Your Balance: Engine Building Tips to Reduce NVH and Increase Life

A high revving racing engine obviously needs a good balance to minimize these destructive forces, but balancing can be just as beneficial to low revving engines, too. Nobody would argue with the fact that engine balancing is right up there with “blueprinting” an engine. The goal is to equalize the reciprocating and rotating forces inside

Quieting Down Chrysler’s Versatile 3.3L And 3.8L Engines

These engines have a mixed reputation for being high-mileage, dependable powerplants as well as noisy motors that can fail at relatively low mileage. First introduced as a family back in 1990, these engines have been upgraded and improved to provide good torque for the necessary applications, reasonable fuel economy and a reputation for durability and

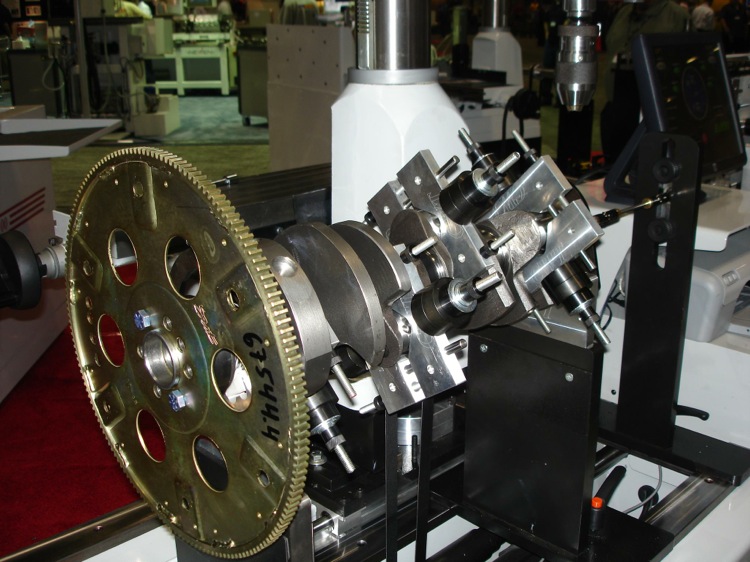

Troubleshooting Common Crank Grinding Problems

Maintaining the crankshaft is one of the most important services that go into a complete engine rebuilding. But before mounting that grinding wheel on a crankshaft grinding machine, inspect it for cracks or damage. This can be done visually or by giving the wheel a “Ring Test.” A good vitrified wheel with no cracks will