Shop Solutions April 2021

Disassembling an old stuck engine can be challenging. When valves are stuck in the valve guides, try welding a nut to the face of the valve.

Shop Solutions March 2021

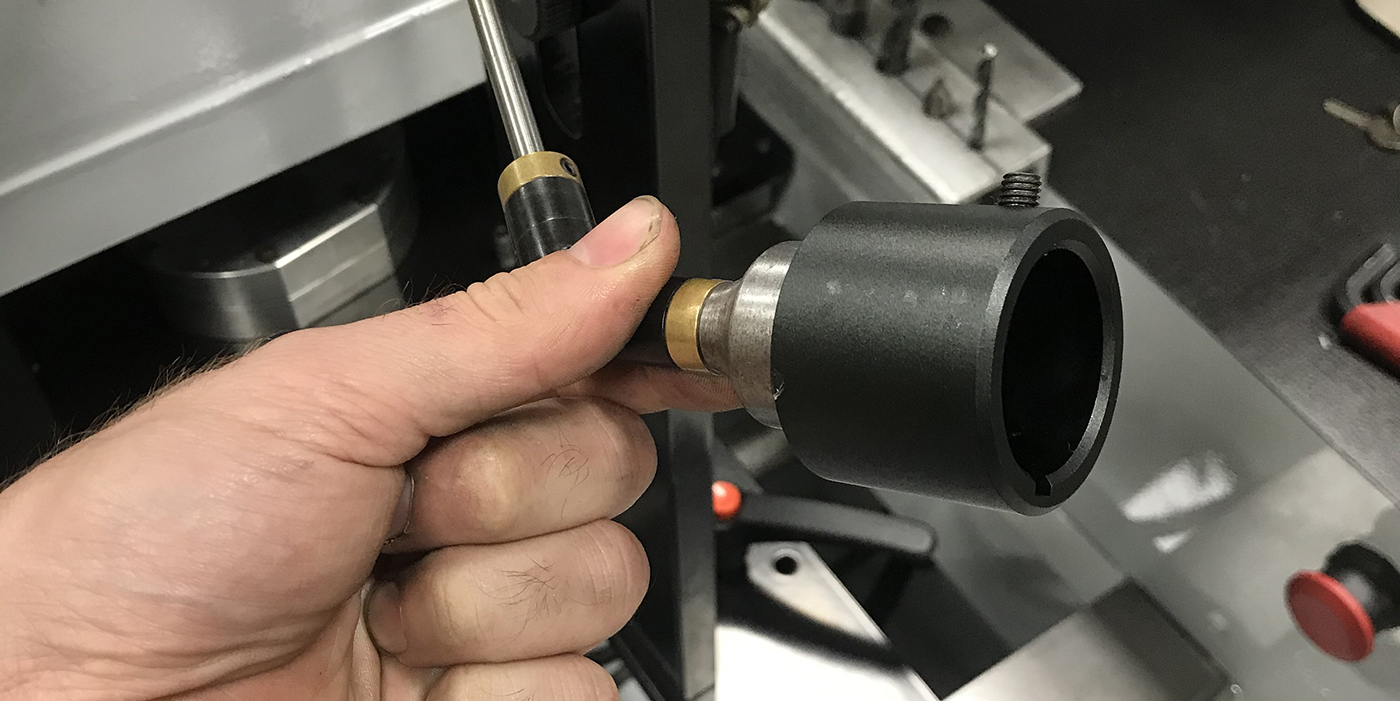

If your shop has a particular crankshaft design you tend to balance on a regular basis, we recommend using a crankshaft snout socket as a locator.

Shop Solutions February 2021

If you work on any high-power adder or high-rpm engines, chances are you will see some fretting on the bottoms of main caps and the backside of the upper rod bearing.

Shop Solutions January 2021

QUICK DRILL CLAMP A very handy drill press clamp set can be made in about 15 minutes from 1˝ angle iron, two carriage head bolts (they fit the t-slots), a couple valve guides for spacers, and two wing nuts. It has a wide operating range and is very quick and easy to adjust or remove

Shop Solutions – December 2020

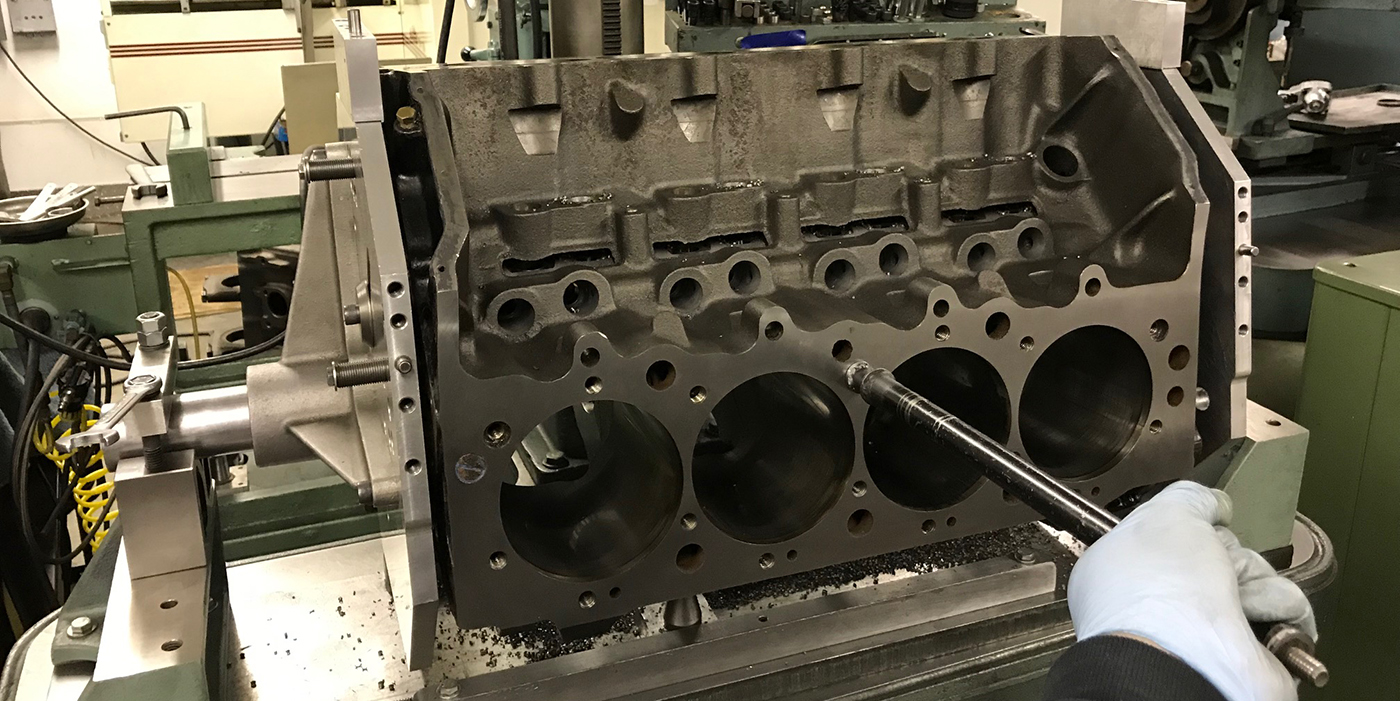

Before machining, remember “Proper Planning Prevents Piss Poor Performance,” and Murphy’s Law will have less of a chance to get you.

Shop Solutions November 2020

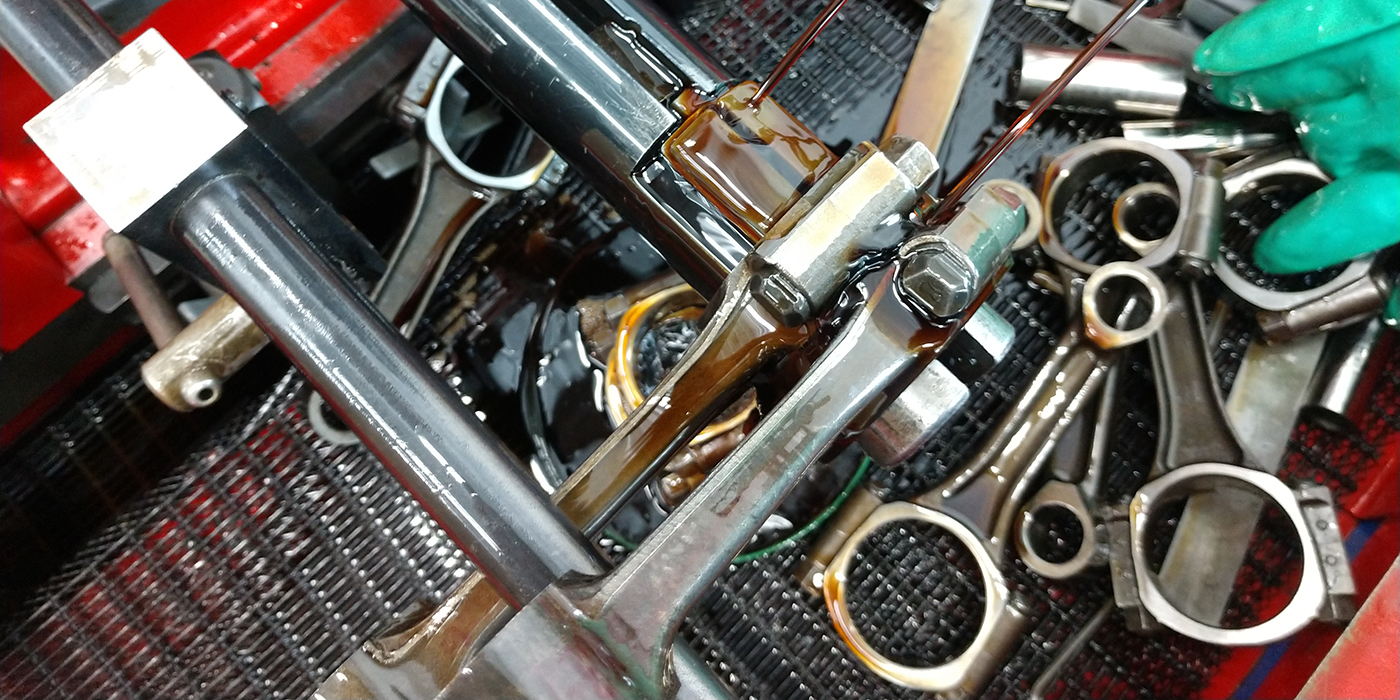

Most of us know that magnetism on parts such as connecting rods is a very bad thing. Heat and friction can cause used rods to become magnetized.

Shop Solutions – October 2020

When resizing connecting rods, I set the oil stream to where I want the stroke to end. That makes it simple and is an easy visual reference.

Shop Solutions September 2020

A simple way to chuck pistons into the lathe is to make a draw rod assembly that goes through the head stock of the lathe.

Shop Solutions August 2020

When I build my bobweights, a simple piece of PVC for a stand makes it easier. Just zero out the scale and add the weight.

July 2020 Shop Solutions

Balancing a crankshaft by drilling large holes in counterweights can leave an appearance of the counterweight that is not pretty. To improve the appearance…

Shop Solutions June 2020

When checking rod-to-cam clearance on stroker engines, you will often find interference.

Shop Solutions May 2020

We do a lot of crankshaft snout rebuilding. To make the process easier, we keep some homespun mandrels that screw into the snout of the crankshaft so it is held secure for welding and machining.