April 2020 Shop Solutions

This saves a lot of time when centering the mandrel on blocks with bed plates.

Shop Solutions – March 2020

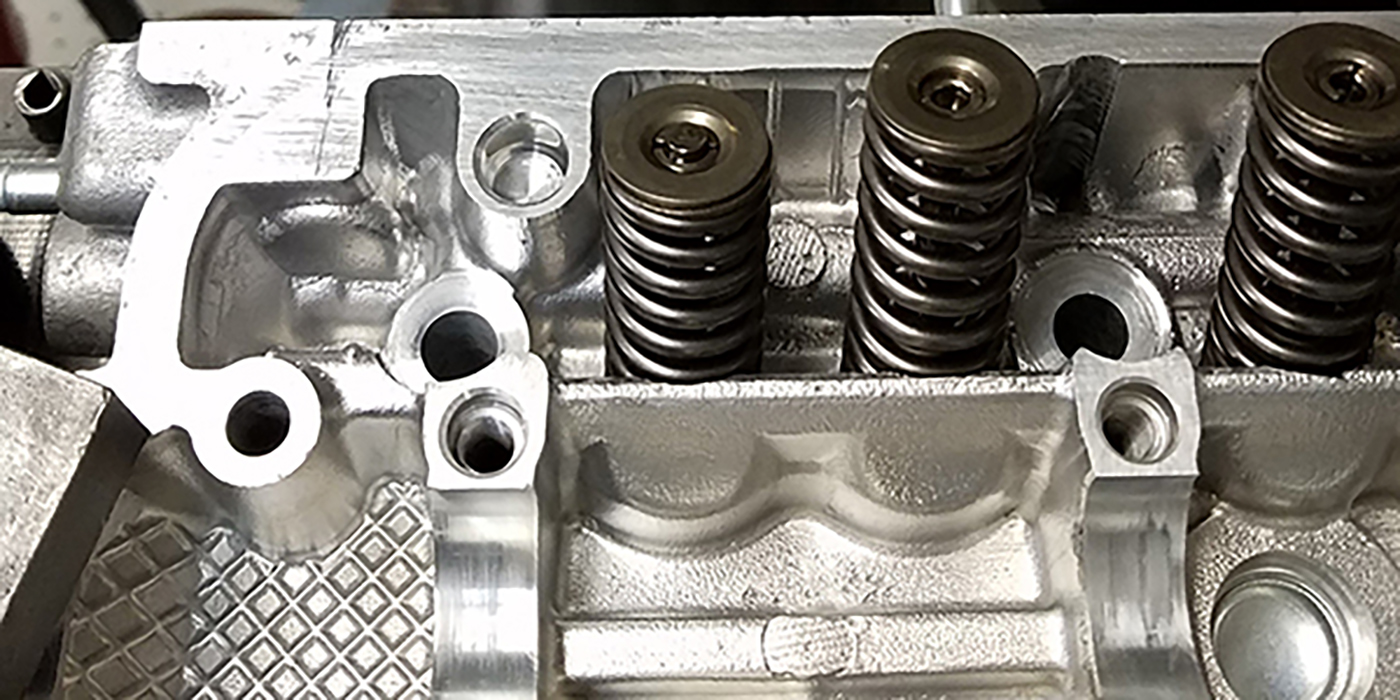

VACUUM TESTING FIXTURES When vacuum testing valves on some heads there may be obstacles in the way. In many cases there will be some exhaust studs in the way like this 3.4L GM. Rather than opening up a can of worms trying to remove the exhaust studs, I look through my pressure testing plates to

Shop Solutions, February 2020

Tips and tricks from the industry’s engine and machine shops.

Shop Solutions – January 2020

Tips and tricks from the industry’s engine and machine shops.

Shop Solutions – December 2019

Tips and tricks from the industry’s engine and machine shops.

Shop Solutions – November 2019

Industry Tips and Tricks

Shop Solutions – October 2019

Industry Tips and Tricks

Shop Solutions – July 2019

Industry tips and tricks.

Shop Solutions – May 2019

There’s nothing worse than having to fit a camshaft after installing new cam bearings, because they are too tight. I dial-bore gauge check all cam bores of the “known offenders.”

Shop Solutions – April 2019

Industry tips and tricks

Shop Solutions February 2019

Instead of having my blocks all over the floor and having to use a two-wheeler all the time to move them around, I use small square moving dollies. Every block goes onto a dolley and effort goes way down.

Engine Pro January Shop Solutions

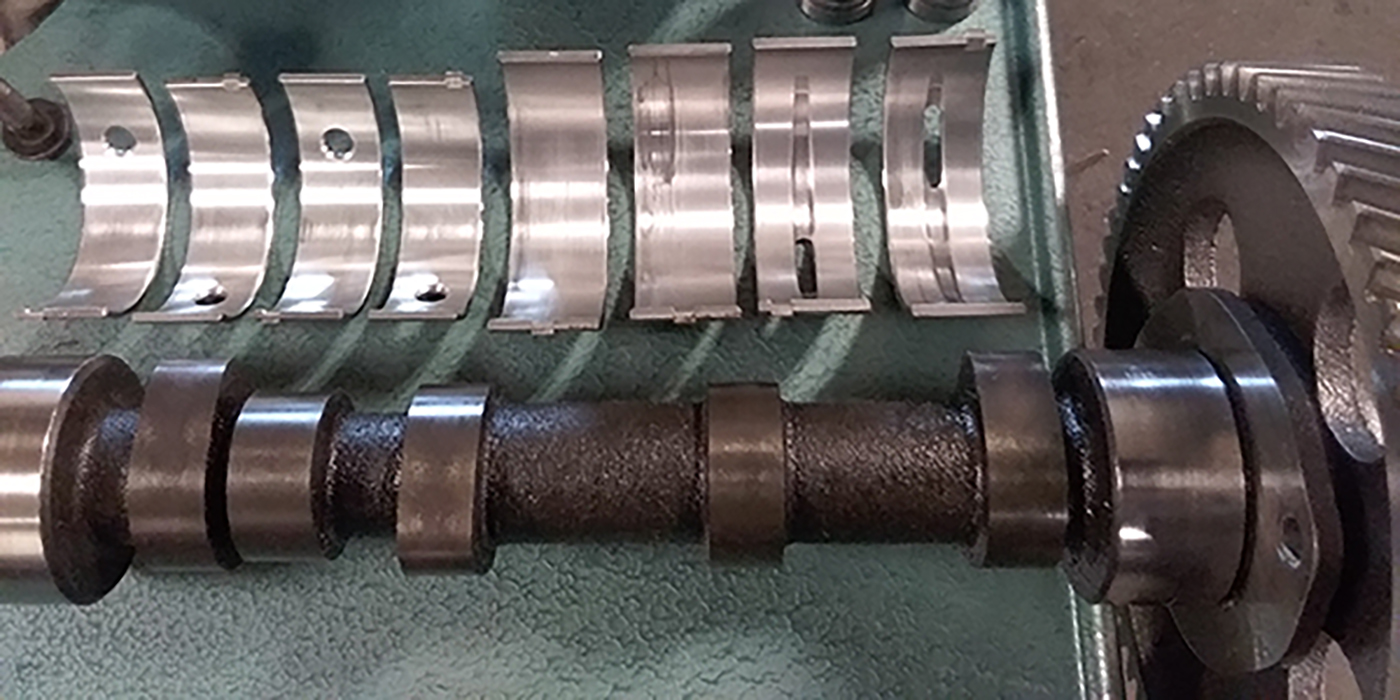

CAM BEARING ISSUES LIKELY TIED TO BURRS We’ve found that almost all issues related to camshafts being too tight in the bearings are caused by burrs in the cam tunnel, which were caused by the original bearing installation at the factory. This is especially true with split cam bearings found in an LS or late