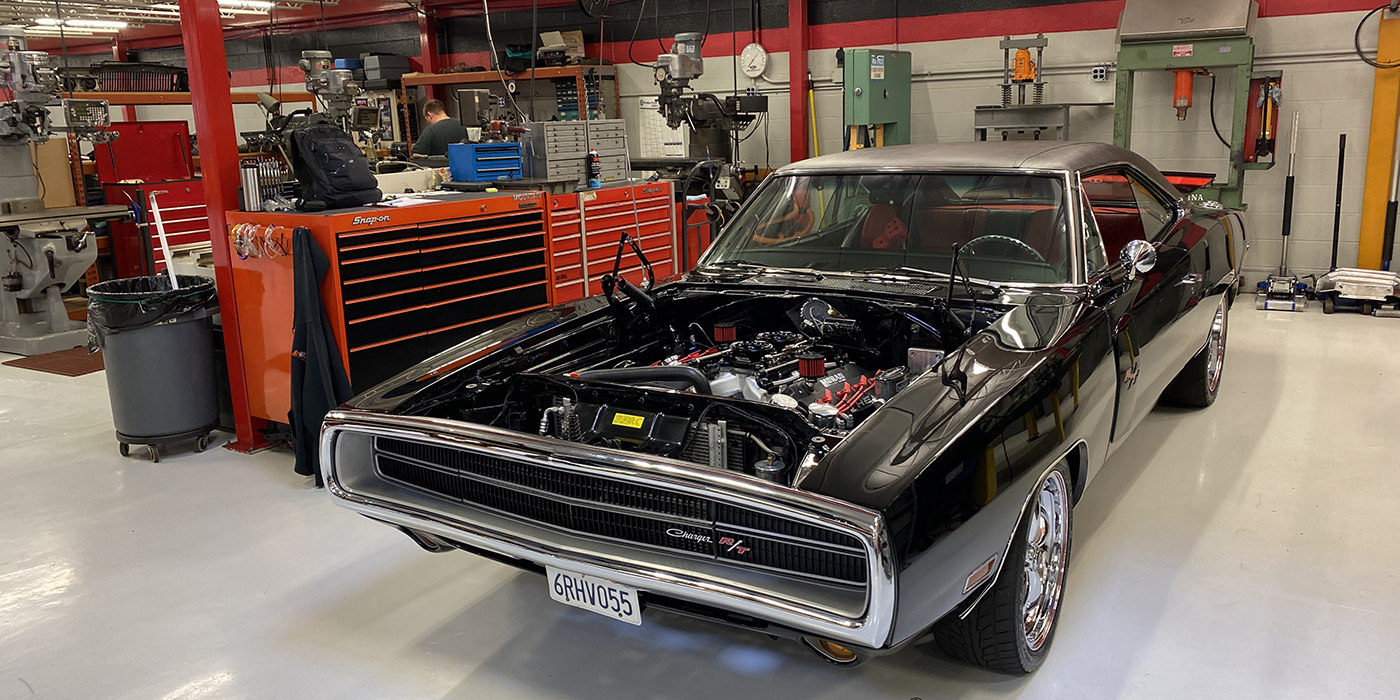

Adding Additional Shop Capabilities

Many engine shops are opting to control their projects and builds from point A to point B, leaving the customer with a ready-to-run package. In order to do this, shops have to add capabilities such as installation work, fabrication work, transmission work, and even suspension and chassis work, in some cases.

Engine Pro Shop Solutions – March 2018

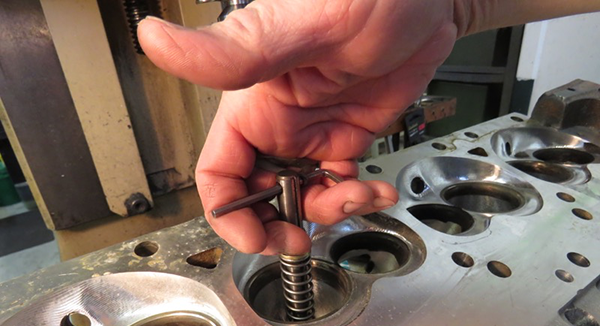

I use an 1/8-inch allen wrench to insert and extract the pilot while doing valve jobs on cylinder heads. I would frequently misplace this little tool between seats, so I started using a rubber band to keep it attached to the palm of my hand.

Engine Pro Shop Solutions – February 2018

ROD TO CAM CLEARANCE GAUGE Using a plastic banding strap as a feeler gauge works great to check for clearance. The straps are generally .035˝-.045˝ thick, so you might want to double them up to check for the minimal .050˝-.060˝ clearance recommended. These work great as they easily bend to any curvature you need. If

Shop Solutions – May 2017 Edition

I call this my “Easy Riser” for Harley cylinders. It is a 2.5L GM block that I have bored to two different sizes to accommodate different cylinder bottom sizes. I use bolts installed into head bolt locations to prevent rotation of the cylinders. I only hone cylinders on this, boring is still done on parallels. This is way easier than horizontal honing on a Sunnen rod hone with a cylinder hone adapter.