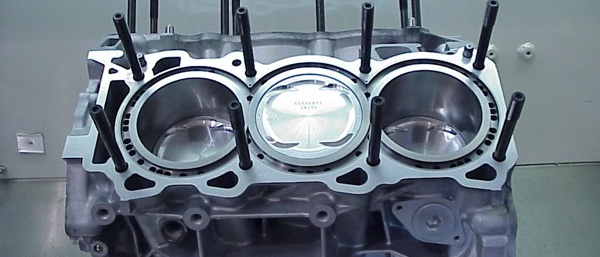

Darton Ford Modular Seat Tight Sleeve

This sleeve makes the block much stronger than the stock aluminum using ductile iron sleeves.

Darton MID Sleeve Kit

Excellent for street or strip applications, Darton’s ductile iron MID sleeve kits offer 130,000 psi of tensile strength.

Sleeving an Engine – Part 2

Once you’ve selected your sleeve, you have to make sure it’s properly installed and machined in order to put the engine back together. Steve Morris of Steve Morris Engines explains the sleeving process.

Sleeving an Engine – Part 1

There are a few different sleeve types when it comes to repairing a block or setting up your engine for additional horsepower. Steve Morris of Steve Morris Engines discusses the different options and what he likes to do in his engine builds. This is Part 1 of a two-part video.

Circling the Potential of Cylinder Sleeves and Liners

What do cylinder sleeves and a certain rodentary rock band from the ‘80s have in common? You guessed it, the shape. But we’re going to leave the rockin’ to the hair guys and the talkin’ to the car guys, so for the sake of this article, we’ll just be covering the first one.

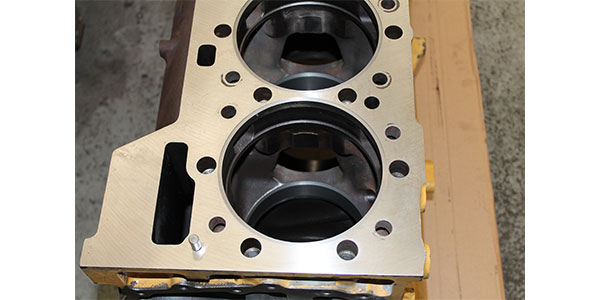

Sleeves & Liners – Selection and Installation

Engine sleeves have long been used to repair worn or cracked cylinders that can’t be bored to oversize. Installing a sleeve can save a block that would otherwise be unrebuildable. But sleeves can also be used to strengthen cylinders, especially in performance engines that are being pushed way beyond their original design tolerances. A prime

Lining Up Sleeve and Liner Work

Whether their purpose is going to be repairing an OE application or to go all out in the restructuring of the engine block, liners and sleeves have to be able to perform a number of tasks. Here are some tips to help you with their installation: