Designing a Better LS Engine

After a customer wanted a Steve Morris Engines’ SMX in an LS version, Steve saw the upside and potential in the market, and a challenge to build a better LS.

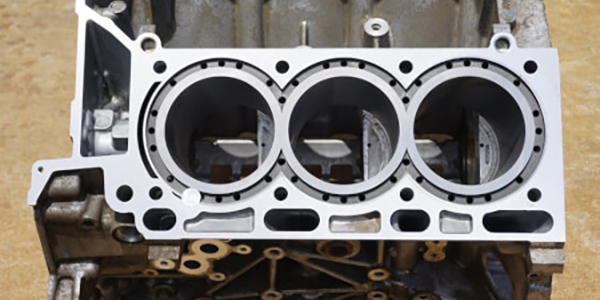

Darton LS Seal Tight Sleeve Kits

These kits allow you to add much more strength to LS blocks even at bigger bore sizes.

Darton Ford Modular Seat Tight Sleeve

This sleeve makes the block much stronger than the stock aluminum using ductile iron sleeves.

Darton Ford 3.5L EcoBoost MID Kit

Easily increase bore size or stay with the stock bore and push 40+ psi of boost.

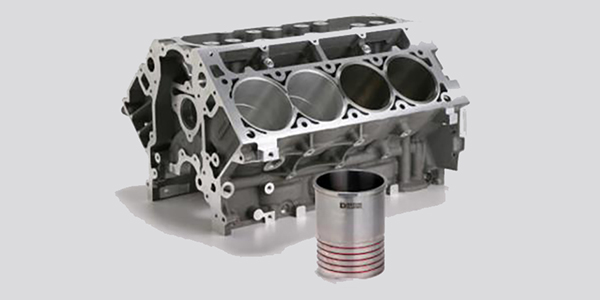

Darton MID Sleeve Kit

Excellent for street or strip applications, Darton’s ductile iron MID sleeve kits offer 130,000 psi of tensile strength.

Darton Sleeves’ Seal Tight Sleeve Kits

Darton’s sleeve kit maximizes fitment and installation ease.

Installing Flanged Sleeves in a Cummins Block

Jeff McCord at LinCo Diesel Performance walks you through the necessary steps for properly sleeving a block. It might sound like a simple process, but any errors can mean catastrophic head failure down the road.

Press Fitting Cylinder Sleeves

There’s something extremely satisfying about a good sleeve job on an engine. There’s also a number of ways sleeves can be installed, so Jeff McCord of LinCo Diesel Performance shows you the way his shop does it and how it helps in high-horsepower diesel applications.

Melling 6.7L Powerstroke Oil Pump Kit and Sleeve Installation

In this video, Melling’s Tech Director Cale talks about the proper procedure for installing the oil pump kit and sleeve for the 6.7L Powerstroke engine. Melling part number K567.

Sleeving an Engine – Part 2

Once you’ve selected your sleeve, you have to make sure it’s properly installed and machined in order to put the engine back together. Steve Morris of Steve Morris Engines explains the sleeving process.

Sleeving an Engine – Part 1

There are a few different sleeve types when it comes to repairing a block or setting up your engine for additional horsepower. Steve Morris of Steve Morris Engines discusses the different options and what he likes to do in his engine builds. This is Part 1 of a two-part video.

Inside PowerBore Cylinder Sleeves

Engine Builder gives you an inside look at PowerBore Cylinder Sleeves’ Salem, OH manufacturing facility. See the process PowerBore uses to manufacture its sleeves and install them into an engine. For more information: PowerBore Cylinder Sleeves