Dry Sleeving Engines

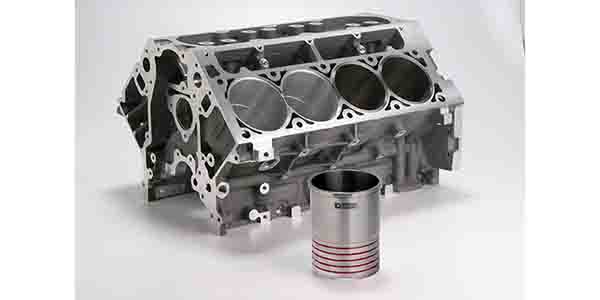

As aluminum continues to be a preferred material for newer engine blocks, and as existing cast iron blocks continue to be driven for more and more miles and under tougher and tougher operating conditions, sleeves continue to be the saving grace.

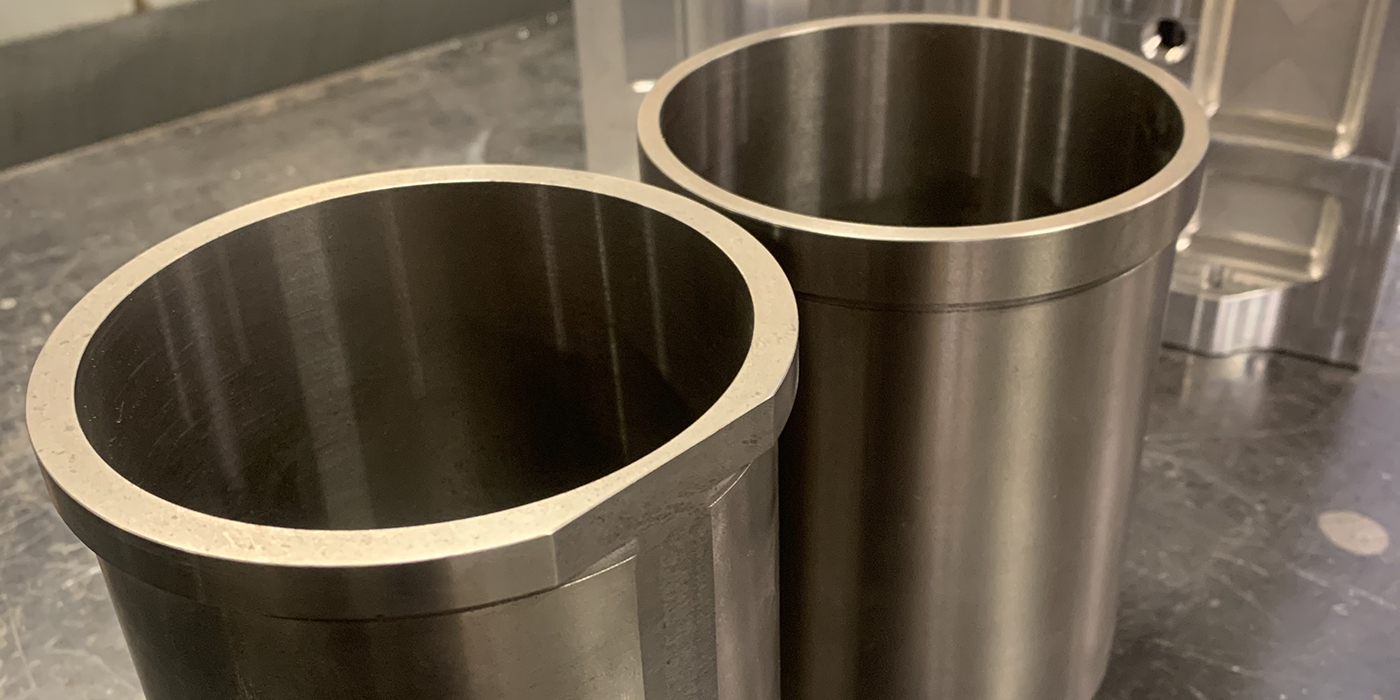

Sleeves and Liners – Metallurgic Magic

Dry sleeves and wet liners have long been used to repair and restore cracked or worn engine cylinders, but they are also used to reinforce aluminum blocks that are being built for serious performance applications.

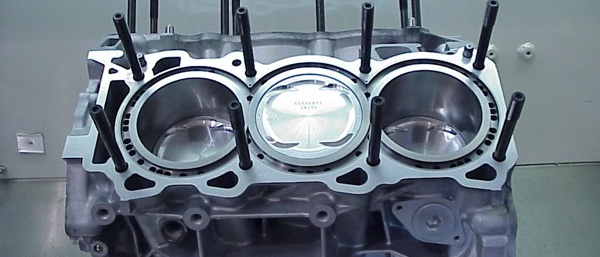

Honing Aluminum Blocks

Manufacturers who produce “linerless” hypereutectic aluminum blocks today include Audi, BMW, Honda, Mercedes, Porsche, Volkswagen, Volvo, and Yamaha. Most late-model engines have aluminum blocks to save weight, including most of the familiar domestic V8s such as Chevy LS, Ford 4.6L modular and 5.0L Coyote, and Chrysler 5.7L and 6.1L Hemi. Yet these have iron sleeves.

Liners and Sleeves

Sleeves are certainly not new technology and experts say that, for the most part, engine builders and machine shops understand the use and functionality well. But is a liner and a sleeve the same thing? Is a hole just a hole? Publisher/Editor Doug Kaufman takes a deeper dive.

Piston and Sleeve Finishing and Break-In Tips

When finishing diesel cylinder bores or sleeves, a two or three step process that results in a plateau finish is usually best to reduce ring break-in and seating time. The type of honing stones, feed and pressure used to finish the cylinders will vary depending on what kind of finish you want to achieve.

Lining Up Sleeve and Liner Work

Whether their purpose is going to be repairing an OE application or to go all out in the restructuring of the engine block, liners and sleeves have to be able to perform a number of tasks. Here are some tips to help you with their installation:

The Demands on Diesel Pistons and Sleeves

The pistons are some of the hardest working components inside a diesel engine. Diesel engines are high compression, high heat engines that demand a lot from their pistons. Compression ratios are typically in the 16:1 to 20:1 range, which improves thermal efficiency and fuel economy, but also creates more pressure. Cylinder pressures in many production