Perfecting Ring Seal Soup

Using modern honing machines, surface finishes, crosshatch angles, ring materials, and coatings all combine to create a more efficient engine.

Sunnen’s Newest Honing Equipment Highlights

As Sunnen Products Co. celebrates 100 years in the industry in 2024, Tom Dustman, sales director for Sunnen, and other Sunnen team members were at the 2023 PRI Show to showcase the latest Sunnen equipment, including the SV-35 and SV-15 honing machines to engine builders and machinists.

Horsepower and Head Gasket Technology

Head gaskets have one of the toughest job in an engine, and now we’re pushing them harder than ever, making it easier to expose the slightest weakness.

Total Seal Surface System

The easy to use, all-in-one kit comes complete with numerous components.

Never Use Scotch-Brite on Aluminum Heads

Scotch-Brite may have some usefulness in the engine shop, but one place it should NEVER be used is on aluminum cylinder head deck surfaces. Using Scotch-Brite is the equivalent of strapping a chain to the cylinder head, having a buddy stand on it and dragging it behind a car on the street. Your results will

Ultra-Smooth Surface Finishes

Determining the correct surface finish means you must consider the metallurgy of the head and block castings along with the type of head gasket you use.

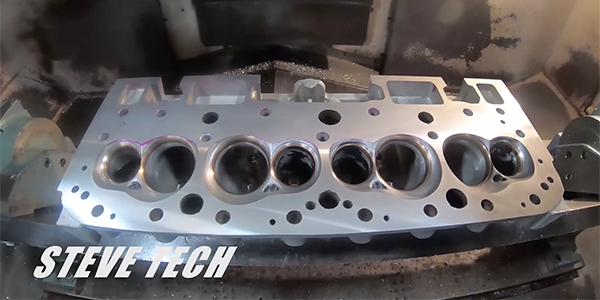

Resurfacing Cylinder Heads

If your cylinder heads don’t have a perfectly flat, shiny surface, they’re not done right and you’ll need to do those again. Steve Morris explains why a correct surface finish is so crucial.

Join PERA for a Webinar on Measuring Tools for Geometry and Surface Finish

In this webinar, Bob Dolder of Sunnen Products will cover: measuring tools for geometry and surface finish, tooling and the variety of different abrasives and how they affect honing engine blocks.

Head & Block RESURFACING EQUIPMENT

Regardless of what type of engine work you do in your shop (stock, performance, diesel, marine or anything that comes in the door), you need the ability to surface heads and blocks. Deck surfaces on high mileage heads and blocks are often corroded, pitted, scratched and/or out-of-flat – especially if the engine blew a head

Surface Finish Testing: Dealing with Dirty Patches

Gauge calibration is a routine process followed by most users of precision gauges. How regular a gauge needs to be checked and its performance documented is usually defined step-by-step in a documentation procedure. Surface finish roughness instruments use a roughness specimen, or “patch,” that is certified for a known wave form to provide a specific