Engine of the Week is presented by

Over the summer, our Engine Builder team spent a full week in and around the Mooresville, NC area with the purpose of visiting various engine shops. One of those shops was Pro Motor Engines owned by Dennis Borem. The engine machine shop has a rich history in all kinds of racing and is still a major shop today, so we were excited to get a tour and check out all that they had going on.

Dennis gave us some history of the shop and told us that the business goes all the way back to the late-1960s and mid-1970s when it was known as Motorsports Research. The company changed hands in the ‘70s and became Pro Motor Engines. Back then, the shop was located in the Chicago area. In 1989, Pro Motor Engines began doing more NASCAR work and the company relocated to Mooresville, NC to the very location it is in today.

Through the ‘90s and early 2000s, Pro Motor Engines primarily built Cup engines for NASCAR. At the time, Dennis worked for a race team by the name of Tri-Star Motorsports.

“We were engine builders who were part of a race team, and our goal was the Winston Cup back then,” Borem says. “We came from the West Coast in the late-‘80s and came to North Carolina and ran NASCAR through the ‘90s and early 2000s. In 2003, the owner of Pro Motor at the time (Pete) wanted to retire, and Mark Smith and our group at Tri-Star Motorsports was growing and needed more room. We merged the two companies in 2004.

“From then until now, NASCAR has been consolidating the number of engine builders involved and we were probably one of the last independents that leased engines in the sport until just a couple years ago. In the last 10 years, we’ve diversified into building engines and doing machine work for other forms of racing such as road racing, endurance racing, drag racing, and more.”

Today, Pro Motor Engines (PME) has over 21,000 sq.-ft. of space, 15 employees, a number of engines at the ready, and a full machine shop filled with lathes, mills, balancers, surfacers, line bores, hones, seat and guides machines, and CNCs.

“We have nearly a dozen machines in one room, and then several CNCs in another room,” Borem notes. “We also have a welder, so if there’s something we can’t fix here, you need a new engine.”

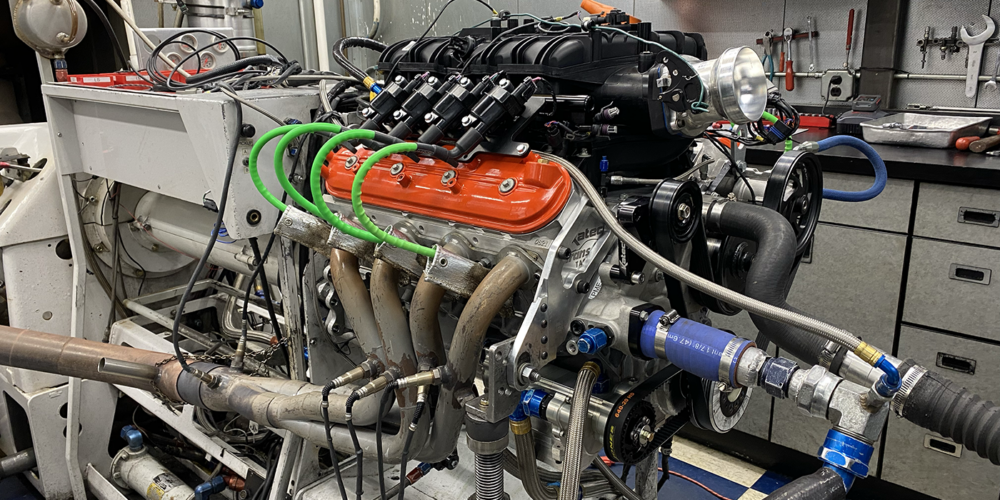

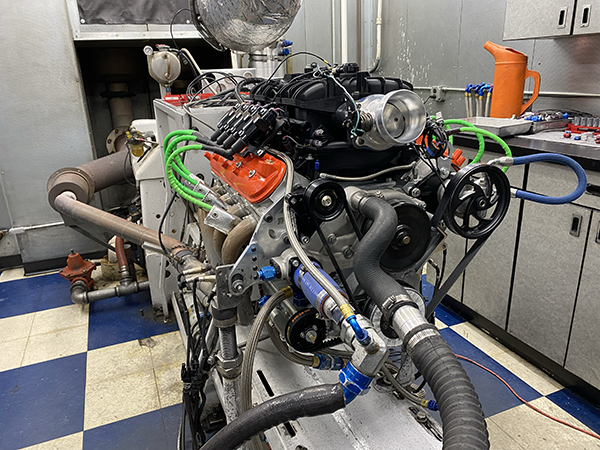

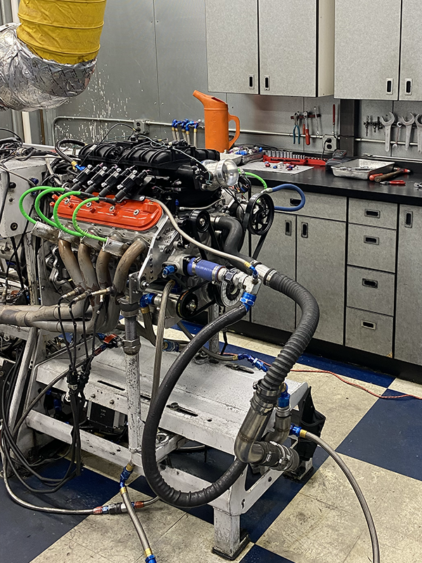

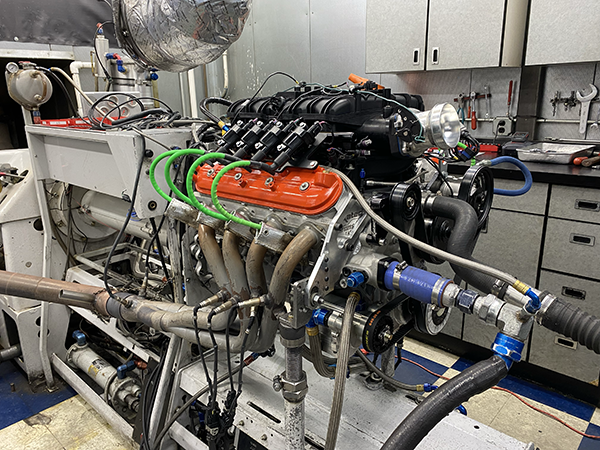

PME also has two engine dyno rooms and an outdoor chassis dyno – all of which race teams take advantage of for testing. In fact, during our visit to the shop, the team had a naturally aspirated LS3 engine for TA2 racing hooked up for some pulls. Dennis gave us the rundown of the spec build.

“This is a GM LS3 engine that is a spec in the TransAm 2 series,” he says. “It’s a TA2 choice engine, and this engine is based off the LS3 – there are some differences. The intake is very much common to a stock intake. It has a throttle body and it has a restriction behind the throttle body to basically keep the power equal between cars, so the competitors have an equal playing field. Because the engine’s built on a spec, we try to keep everything – machine processes, parts and everything – to where when it comes back here we can monitor the power and send out the same product every time.”

The LS3 features a GM block, GM cylinder head castings, which are CNC ported, a GM front cover and rear cover, a GM front drive system, as well as a GM crankshaft with a stock stroke of 3.622”. There’s variances to where PME could run an aftermarket crank, but stuck with a GM option on this particular build. The engine also has Mahle pistons, aftermarket Callies rods, a roller camshaft ground for the spec, and an aftermarket ECU from MoTeC.

“There’s also a carb version of this engine, which we have done several of,” he says. “Some people don’t want to deal with the ECU and all of the maintenance on that end of it, so the simplicity of a carburetor is gaining a little traction in the series also.”

The valvetrain in this engine build also has a lot of GM parts in it. However, the springs are aftermarket from PSI. The pushrod is a little bit thicker wall pushrod. It’s pretty close to stock, but for durability and control PME went slightly thicker.

The oiling system on the LS3 is a Dailey dry sump system, which is an integral pump bolted to the billet pan. The customer could also run a conventional pan with an oil pump and lines. However, most people end up going with the billet system, according to Borem, because the packaging is just a little tighter. The Dailey pump is a four stage system – a pressure stage and three scavenge stages.

In a spec engine scenario, there is little difference from engine to engine, on purpose. For that reason, you may be asking, what’s the differentiator?

“A lot of series have gone to a spec engine or an approved builder,” Borem says. “Anybody can come to the table as long as they use those specs. I always tell people that we all do a good job. There’s a lot of good engine builders out here. I would like to think that our processes are as good as anybody, and I think our service is as good, if not better, than anybody. The difference is taking care of the customer at the end.”

Pro Motor Engines’ LS3 TA2 engine got dyno’d and made just north of 500 horsepower.

“The design of this engine is to run a long time,” he says. “You’d like to get 10-15 races out of it, so the customer gets a good value for their engine. They’ve kept the power down and the rpm down, so the engine shouldn’t hurt itself under normal operating conditions. This engine is going to see anywhere from the corners, however far the driver gets down, up to 6,200-6,400 rpm. It’s durable because it’s not a ton of power, yet the cars are very competitive. The fields at these things can be 45-50 cars. They’re really big fields.”

The TA2 engine in the series has grown and this LS3-based engine is a great package for track day cars and with modifications to this engine, this style engine can also be used to run club racing or SCCA.

Engine of the Week is sponsored by PennGrade1, Elring – Das Original and NPW Companies. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].