What you should know if your business is going international

Not many businesses are satisfied with simply maintaining a local clientele. Just as customers typically want bigger and bigger engines, engine shops are looking to grow their business reach outside their town, city or state. In some cases, engine shops reach an international clientele, making their engines and services available to the world.

While there’s certainly nothing wrong with having your core group of customers, how cool is it to think Queen Elizabeth could be calling up your shop for engine work? Well, not her personally, but Randy Rundle of Fifth Avenue Antique Auto Parts in Clay Center, KS, received a call in 1989 from the Royal Minister of Transportation to do a job on a ’49 Cadillac limousine originally used by Queen Elizabeth II’s mother in the 1949 opening ceremony of the Pan Am Games.

When asked if she would be in the opening ceremony of the 40th Pan Am Games and more or less recreate what her mother did, the Queen agreed, but with the stipulation that she ride in that same ’49 Cadillac.

When asked if she would be in the opening ceremony of the 40th Pan Am Games and more or less recreate what her mother did, the Queen agreed, but with the stipulation that she ride in that same ’49 Cadillac.

The responsibility of tracking down the car fell to the Royal Minister of Transportation, who ultimately found the limo in Winnipeg, Canada, where a banker had bought it unrestored. The Palace went to him and said, “If we restore this car, can we use it in the Pan Am Games? Then you can have it back when we’re done.” So of course that was a no-brainer for him.

The Royal Minister of Transportation ended up going to the end of The Great Race where he saw Randy’s name along the course on the old, Great Race cars and called him up. “He said, ‘Will you do for me what you do for The Great Race cars to make them reliable enough?’” Rundle says. “That’s how I got into that project. It was about a six-month thing. He sent me labels from the palace to put on the package that I shipped to him – the labels had the Queen’s letterhead on it.”

While all international engine work isn’t this glamorous, it is quite the accomplishment to have people around the globe yearning after your engine skills. We spoke to several builders who currently work with clients in different countries to find out what it takes to make international business a success.

Dip Your Toe in the Water

As with any new endeavor, you’ll never know what could have been if you don’t at least make an effort. International business is no different. Sure, you need to have willing customers overseas, but you also have to be ready to support that business.

Scott Eatmon of Eatmon Racing Engines in Wilson, NC has engine customers in Australia, New Zealand, France, Norway, England, Sweden, Mexico and Canada.

“We started doing international business around 2006-2007,” Eatmon says. “I started selling parts internationally and the guys who were buying parts got to asking about complete engines. My first international engine was to Australia in 2007.”

Eatmon says he is glad his parts sales turned into international business. Today, the shop’s business is about 30 percent international.

“We’re proud of the fact that we have engines running all over the world,” he says. “The Internet has made the world a small place, and I would encourage any other engine builder to get out there.”

Eatmon says social media has been great for more than just keeping in touch with family members.

“I had just started an Instagram page about a month or two ago before Engine Builder contacted me. And that’s how you saw me,” Eatmon says, pointing out that visibility is the key to boosting his business. “Maybe a year ago, I started a Facebook page, and I have customers who found me there, do business with me through Facebook and buy parts from me through Facebook.”

If you think it’s hard to find your shop here in the U.S. imagine how much more challengine it will be for someone looking for you from France or Australia and you’re not making the effort to be visible.

Jeff Baldwin, owner of Baldwin Racing Engines in Friedheim, MO, got his introduction to international business through customers finding his shop on forums and through his website.

“We also did all the in-house work for Race Parts Direct, which helped spur some of that international business,” Baldwin says. “We’ve shipped to Iceland, Saudi Arabia, Australia and Mexico. We’ve been doing overseas engine work for roughly 13 years now.”

Randy Rundle says those antique foreign cars in The Great Race have spawned much work than just the Queen. “I do stuff in 22 foreign countries besides the U.S. and Canada,” says the Engine Builder contributor. “My customers virtually come from everywhere. The wealthier customers don’t have any problem going halfway around the world to get something done. If you have what they want and you can provide the services that they need they’ll seek out the expert wherever he is.”

If you want to start international engine work, you have to get your name out there. Once you start getting customers, communication is key.

Communication Breakdown

There are numerous obstacles to doing international business, including time zones, currency exchange rates and shipping, but the most important one is communications.

Good communication with any customer is crucial, of course, but dealing with an international customer is much more difficult if you’re not discussing every detail of the build and other logistics.

“Just make sure that you and the customer are both on the same page and that his expectations and yours are the same. You both need to understand what’s going on,” Rundle says. “You also need to establish a timeline. Customers need to understand it may take six or seven weeks to get an engine to you, and then however long you need to do the job, and then another six or seven weeks from the time you ship it back.”

One of the things that can drive your international business is taking the time to answer people’s questions.

“I believe when customers see that I’m simply willing to have a conversation with them, whether it’s through email or Facebook, I gain them as a customer because I took the time to answer their questions,” Eatmon says.

“One of the things we feel stands out for our international customers is to take pictures of all the parts we use when we build their engines – we email our customers photos of the block, the crank, the internals of the engine…this makes them feel a lot better, I believe, because they’re seeing what they’re getting. They’re actually seeing the progress of their engine build as its going together. Being so far away, it makes the customer feel a lot better about sending $20,000 or $30,000 to somebody they’ve never seen or met before. After all, they don’t come to the shop to get the engine – they just wire the money and we ship the engine out.”

In addition to photos, Eatmon says he will even send international customers a dyno video as well as a build sheet with part numbers and specifications on the engine.

“We do that so if they do have an issue or whatever, they know what to look for and what to get,” he says. “When it comes time to rebuild the engine, they can source some of these parts locally wherever they’re at. Most of the time, however, it’s custom stuff and they end up calling back and I put together a rebuild package for them with rings, bearings, gaskets, valves, pistons, etc. and ship it to them so they can rebuild the engine themselves.”

His tactics seem to be working – Eatmon says he has an Australian customer who has purchased three complete engines from him.

Like Eatmon, Baldwin says he finds it tough to get on the phone with international customers, resorting instead to email or social media.

“Phone calls can be a little tricky with the time differences,” Baldwin says. “Honestly, social media and email are the two most widely used forms of communication for international customers. Between myself and my wife, DeAnna, we take care of responding to a lot of those notes.”

In addition, says Baldwin, a handful of customers are comfortable going back and forth through Facebook. “We also have an employee who watches our Facebook accounts, and he handles some communication that we miss or just can’t get to. It’s a little overwhelming sometimes between the emails, phone calls and Facebook, but it’s part of the new way of doing business.”

Baldwin stresses that communication is truly the most important aspect of international business. You have to make sure you’ve got everything customers need and want on the front end because you don’t want to have to re-ship anything due to the expense.

Communication also ensures that you as a builder are following the different rules and regulations of the countries you’re shipping engines to.

“One of the most important things that we ask international customers is what type of fuel they’ll be running,” Eatmon says. “When people buy racing engines locally or even if they’re elsewhere in the U.S., we pretty much know they’re going to have access to 110 octane or better race fuel. Compression is not an issue – we don’t have to worry aobut the pistons and valves. However, when you sell an engine internationally, a lot of countries don’t have anything better than 100 octane fuel.”

The octane can limit the amount of compression an engine can have, and in addition, many countries only have unleaded fuel.

“Most of the race gas here in the U.S. is leaded race fuel – 110, 112, 114 octane,” Eatmon says. “When you go outside the country, just about everything’s unleaded, so you have to have coated valves for the unleaded fuel. You have to limit your compression ratio to around 12:1, because their fuel is only 100 octane. A lot of the guys in Australia use aviation fuel but as good as they can get is only 100 octane.”

There are different rules for different race series all over the world regarding cubic inches or rpm limits. Eatmon says he has found in Australia that some of the circuit racing classes have an 8,000 rpm limit.

“When we build engines for that particular class, it takes a different camshaft combination – what we’re selling are NASCAR-type engines, which run 8,500 rpm to 9,000 rpm. These guys want these engines, but they have an 8,000 rpm limit,” he says. “So we use a different intake manifold and different camshaft combination to try to bring the power band down so it will peak out at 7,800 to 8,000 rpm. That can be very challenging to do on an engine that was built to peak out at 9,000 rpm like these NASCAR engines are. But we’ve been able to do it pretty well and get the power band down to be able to run well according to their limits.”

Payment

While communication is imperative to doing the job right and getting the engine to the right location, payment is what keeps you in business. Experts say international engine work can get pricey. The first obstacle is understanding currency exchange rates.

“The money exchange is kind of the weird thing,” Baldwin says. “With the Australian engine we recently built, every $20,000 AUD they spend is $14,000 U.S. So it’s a big difference as far as the money loss from over there to here. But, they’re used to it, and they knew going in that they’re paying the premium.”

According to Eatmon, many of his international customers will watch for when the U.S. dollar is down to make payments on their engine work to get a better value.

“It takes a lot of faith and trust in someone halfway around the world to send you $20,000 to build a motor when they’ve never seen you before,” Eatmon says. “You have to maintain a good reputation and you have to look after your customers well to keep international business going.”

Eatmon, Baldwin and Rundle all recall slight trepidation when doing their first international job and making sure they got paid properly.

“I’ve been doing this 33 years now, and I was kind of worried about some of those first foreign jobs,” Rundle admits. “I would call the banks to make sure that there’s enough money in the account. Most of those guys will have a $120,000 credit limit on their Visa, so eventually I quit calling on the banks.”

To accommodate international business, Baldwin set up separate bank accounts to handle the wire transfers versus putting it directly into his shop’s standard accounts. And Eatmon agreed that most international customers will either pay by wire transfer or credit card. But no matter how the customer pays, most engine builders required a 50 percent down payment.

“Depending on the cost of the engine, we try to the deposit up front,” Eatmon says. “As we do the work, we email the pictures and videos, so when we’re done and we have it completed ready for shipping, we quickly get a shipping quote. Shipping costs can fluctuate, so once we get a shipping quote and they send the remaining balance due, we ship the engine out.”

Another expense for the buyer will be import duties and customs taxes. Different countries vary on what they charge for import fees. A lot of buyers are not aware of this until the engine reaches their country and they try to pick it up only to have the government tell them they owe another $1,000 – $1,500 for import fees.

“That’s something buyers have to consider,” Eatmon says. “If the engine costs $20,000, freight to Australia is usually $1,200-$1,300 via five- to seven-day airfreight. Then on top of that they’ll have those import duties/customs duties.”

Eatmon does suggest that customers look into whether or not the United States has a free trade agreement with their country. A free trade agreement document can save the buyer about 5 or 10 percent on their import fees.

“This can give them more of an incentive to deal with us when they go to calculate all the costs of the engine, the freight, the insurance and the import duties,” Eatmon says.

Shipping

Once the build is done and details have been confirmed, and the payment has been received, you’re ready to ship the engine out. Of course, this won’t be as simple as a customer coming to pick up the engine or even shipping it a state over. There are several precautions you must take as an engine builder, and several things your customer will need to know.

Step one to shipping your engine is making sure you have all the necessary parts ready to go.

“It’s definitely not cheap, so you don’t want to leave anything out of the package when you send it,” Baldwin says. “You want to have all your ducks in a row and make sure it’s built to their specs and have it 100 percent ready to rock and roll before it gets there.”

Shops such as Baldwin Racing Engines and Eatmon Racing Engines dyno their engines before they ship.

“The engines get dynoed and tested before they leave so we’ve got a pretty good handle on whether they’re ready to run when customers get them,” Baldwin says. “You hope you don’t have to deal with any issues, but it’s an engine, so you never know for sure.”

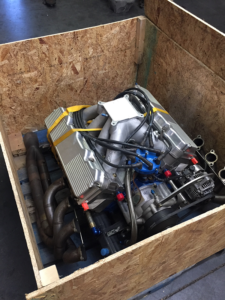

Step two to shipping your engine is preparing it for the trip in either a wooden crate or special reusable shipping container.

“You do need to put them in a container to ship them,” says Eatmon. “I have shipped them before with just shrinkwrap and strapped down to a pallet and I’ve had a valve cover crack and an alternator that got bumped and bent the pulley. That was years ago, when I first started doing it. After I had a damaged engine a time or two, we determined we needed to put everything in an enclosed container. Now we always ship the engines in a container, either a poly one from a company such as Scribner or Endural, or we put it on a pallet and we’ll build a wooden box around the engine.”

Jeff Baldwin says he will also internally brace the engines and any other parts in the crate to ensure everything makes the ride with no issues.

“Once the engine is crated and prepped for shipping, you’ll typically have three copies of the invoice,” Rundle says. “One will go to the customer, one will go to customs and one will go to the freight company that’s shipping it. And you’ll typically put phone numbers on of the recipient.”

Once the engine ships, time frames for delivery can be seven to 10 days depending on a variety of circumstances. But one thing is for sure – if you did all of these things the right way, you’re going to have one very happy customer at the end and, hopefully, a line of future international clientele awaiting your response. ν