Engine of the Week is presented by

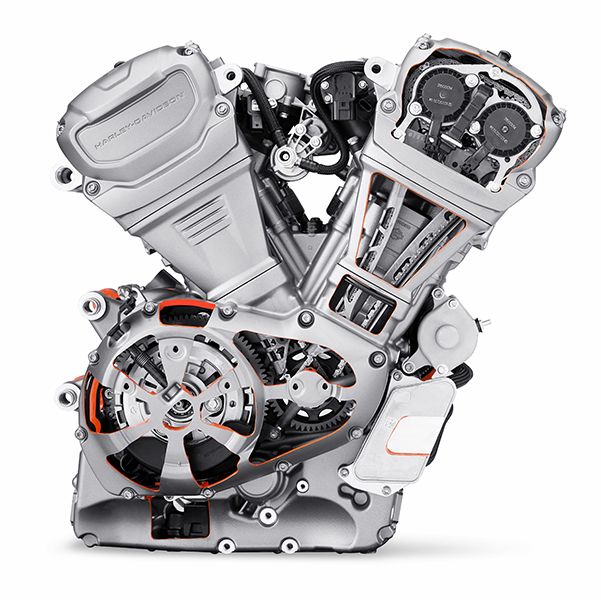

Through its history, Harley-Davidson has embraced technological evolution while respecting the heritage of its brand with engines that produce real-world performance for real-life riders. One of Harley’s newest clean-sheet, advanced-design efforts is the Revolution Max 1250 engine – an all-new, liquid-cooled V-Twin to power the Pan America 1250 and Pan America 1250 Special.

The Revolution Max 1250 engine was designed to offer flexible, engaging performance with a broad powerband that builds to a rush of high-rpm power surging through the redline. The V-Twin engine has been tuned specifically to deliver desirable power characteristics for the Pan America 1250 models with an emphasis on smooth low-end torque delivery and low-speed throttle control applicable to off-road riding.

A focus on performance and weight reduction drove both vehicle and engine architecture, material choices and aggressive component design optimization. To minimize overall motorcycle weight the engine is integrated into the Pan America models as the central member of the chassis. The use of lightweight materials helps achieve a desirable power-to-weight ratio.

The Revolution Max 1250 engine was assembled at the Harley-Davidson Pilgrim Road Powertrain Operations facility in Wisconsin. The V-Twin features a 1,250cc displacement with a bore and stroke of 4.13˝ (105mm) x 2.83˝ (72mm) and is capable of 150 horsepower and 94 ft.-lbs. of torque with a peak rpm of 9,500 and a 13:1 compression ratio.

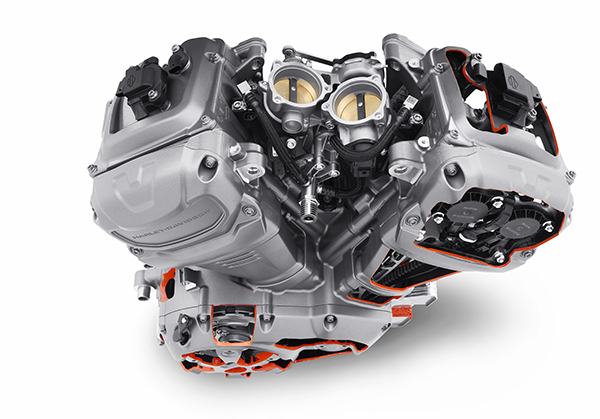

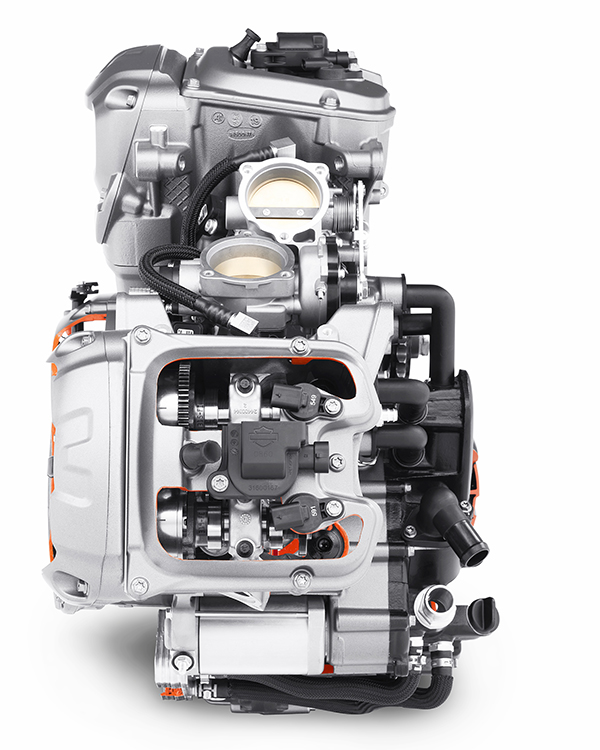

The engine’s V-Twin design provides a narrow powertrain profile that centralizes mass to enhance balance and handling, and also provides ample foot/leg room for the rider. A 60-degree V angle of the cylinders keeps the engine compact while providing space between the cylinders for dual down-draft throttle bodies that maximize air flow and increase performance.

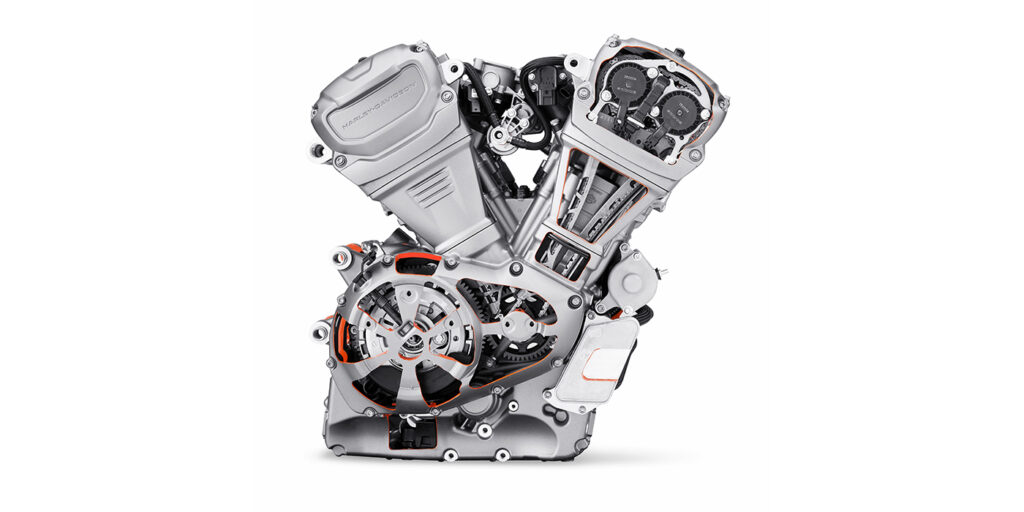

Reducing the weight of the powertrain contributes to lower motorcycle weight, which enhances efficiency, acceleration, handling, and braking. The use of finite element analysis (FEA) and advanced design optimization techniques in the engine design stage minimized material mass in cast and molded components. For example, as the design progressed, material was removed from the starter gear and camshaft drive gears in an effort to lighten these components. Single-piece aluminum cylinders with nickel silicon carbide-surface galvanic coating are a lightweight design feature, as well as lightweight magnesium rocker covers, camshaft covers and primary cover.

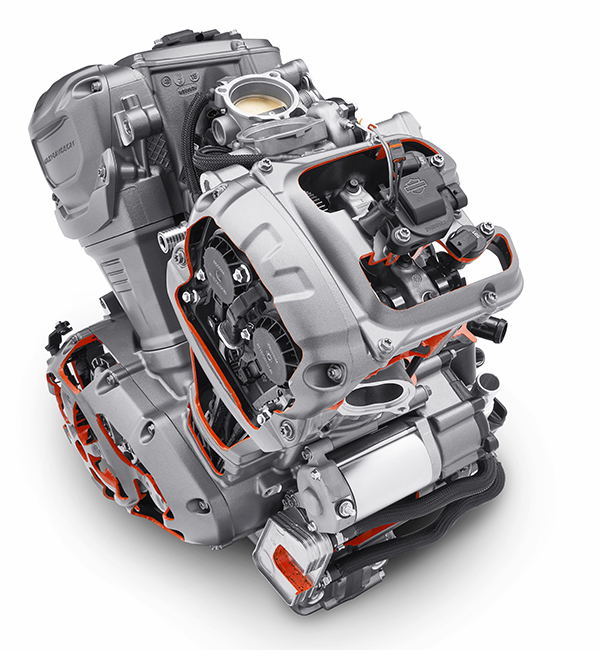

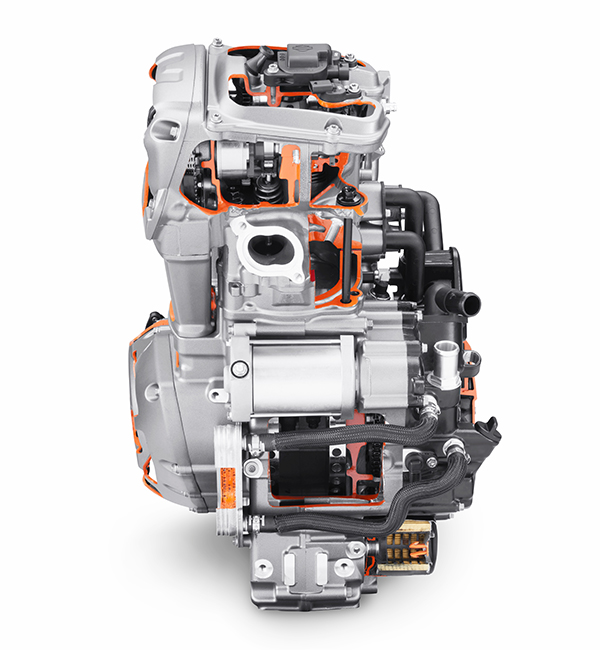

According to Harley-Davidson Chief Engineer Alex Bozmoski, the Revolution Max 1250 powertrain is a structural component of the motorcycle chassis. Therefore, the engine serves two functions – providing power and acting as a structural element of the chassis. Eliminating a traditional frame significantly reduces motorcycle weight and results in a very stiff chassis. A front frame element, mid frame element and the tail section bolt directly to the powertrain. The rider realizes optimized performance due to a significant weight savings, a rigid chassis and mass centralization.

When it comes to the V-Twin engine, heat is an enemy of both durability and rider comfort, so liquid cooling the engine maintains a stable and controllable engine and oil temperature for consistent performance. The powertrain performance is enhanced by tight component tolerances that can be achieved when engine temperature is controlled because there is less expansion and contraction of metal parts.

In addition, desirable engine sounds and a stirring exhaust tone can predominate because noise from internal engine sources is reduced by liquid cooling. The engine oil is also liquid cooled, which ensures that engine oil performance and durability will be maintained in challenging conditions.

The coolant pump is internal and features high-performance bearings and seals for extended service life, and coolant passages are integrated into a complex stator cover casting to save weight and reduce powertrain width.

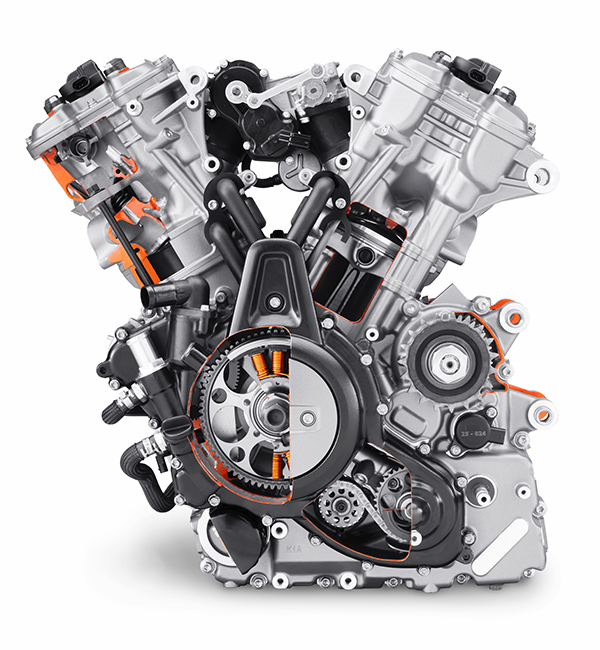

Internally, the Revolution Max 1250 has two crankshaft connecting rod journals that are offset by 30 degrees. Harley-Davidson leveraged its extensive experience in flat track racing to help inform the cadence of the Revolution Max 1250 engine power pulses. The 30-degree offset creates a 90-degree firing order that produces a smooth power delivery, especially at higher rpm, and the power pulses of a 90-degree firing order may improve traction in some off-road riding situations.

Attached to the crank and rods are forged aluminum pistons, which feature a 13:1 compression to improve engine torque at all speeds. This high compression ratio is made possible by advanced knock detection sensors. The engine will require premium-grade 91 octane fuel to make maximum power, but will run on lower-octane fuel and is protected from detonation by the knock sensor technology.

The base of the piston is chamfered so no piston ring compression tool is required for installation. The piston skirt has a low-friction coating and low-tension piston rings reduce friction, which improves performance. The top ring land is anodized to enhance durability and oil cooling jets are aimed at the bottom of the pistons to help dissipate combustion heat.

Up top, the V-Twin engine uses four-valve cylinder heads (two intake and two exhaust) to permit the largest-possible valve area. This provides strong bottom-end torque with a smooth transition to peak power because the flow of gases through the combustion chamber is optimized to match the desired performance requirement and engine displacement.

The exhaust valves are sodium-filled to better dissipate heat. Suspended oil passages within the heads are made possible by a complex casting technique and reduce weight because the head wall thickness is minimized.

The cylinder heads are cast from high-strength 354 aluminum alloy. Because the heads act as a chassis mounting point, they are designed to be flexible at that mounting point but rigid over the combustion chamber. This is accomplished in part through targeted heat treating.

The heads also feature separate intake and exhaust camshafts for each cylinder. The DOHC design facilitates higher-rpm operation by reducing valvetrain inertia, which produces higher peak horsepower. The DOHC design also permits independent Variable Valve Timing (VVT) on the intake and exhaust cam, optimized for the front and rear cylinder, to broaden the powerband.

Specific cam profiles are selected to produce the most-desirable performance characteristics. The drive-side camshaft bearing journal is part of the drive sprocket, a design that makes it possible to remove the camshaft for service or a future performance upgrade without disassembling the camshaft drive.

To cap off the valvetrain on the Revolution Max 1250, Harley used roller-finger valve actuation with hydraulic lash adjusters. This design ensures that the valves and valve actuators (fingers) are in constant contact as engine heat changes. The hydraulic lash adjusters make the valvetrain maintenance-free, saving the owner time and cost. This design maintains consistent pressure on the valve stem, which facilitates more-aggressive camshaft profiles, which can boost performance.

Helping air flow in the engine are dual down-draft throttle bodies located between the cylinders, positioned to create minimal turbulence and impedance to air flow. Fuel delivery can be optimized individually for each cylinder, which can improve economy and range. The central location of the throttle bodies permits the ideal position of an 11-liter airbox over the engine. Airbox capacity is optimized for engine performance.

The airbox is shaped to permit use of tuned velocity stacks over each throttle body that utilize inertia to pack more air mass into the combustion chamber, which can increase power output. The airbox is formed of glass-filled nylon with integrated internal ribs that help quell resonance and muffle intake noise. A forward-facing intake snorkel directs intake noise away from the rider. Silencing that intake noise permits desirable exhaust tones to predominate.

Keeping the engine happy is a robust dry sump oiling system with the oil reservoir incorporated into the crankcase casting. Triple oil scavenge pumps evacuate excess oil from three engine cavities – crankcase, stator cavity and clutch cavity. The rider gains optimal performance as parasitic power loss is reduced because internal engine components do not have to rotate through excess oil.

A windage tray prevents the clutch from aerating engine oil, which could degrade oil delivery. Oil delivery to the main and rod bearings is done through the center of the crankshaft, a design that enables low oil pressure (60-70 psi) that reduces parasitic power loss at high rpm.

Making the Pan America 1250 a comfortable ride are internal balancers that cancel most engine vibration to enhance rider comfort and improve vehicle durability. A primary balancer located in the crankcase manages the primary vibration created by the crank pins, pistons and connecting rods, and also a “rolling couple,” or side-to-side imbalance, caused by the off-set cylinders. A secondary balancer located in the front cylinder head between the camshafts complements the primary balancer to further reduce vibration.

Lastly, the Revolution Max is a unitized powertrain, meaning that the engine and six-speed transmission are housed in a common case. The clutch features eight friction plates designed to provide consistent engagement at maximum torque throughout the life of the clutch. Compensation springs in the primary gear smooth out torque pulses from the crankshaft before they reach the transmission, providing consistent torque delivery.

In total, the Revolution Max 1250 V-Twin is an excellent example of why Harley-Davidson motorcycles remain such sought after machines.

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor, Greg Jones at [email protected].