Engine of the Week is presented by

Earlier in the year, we spotlighted a twin-supercharged Hemi engine built by Arrington Performance, an engine we saw at the 2021 PRI Show. It was a build done by our pal Mike Copeland, who happens to own Arrington Performance as well as Diversified Creations. We also showcased Mike’s unique 392 Hemi-powered Dodge Rampage, which we saw at the 2021 Hot Rod Power Tour. Mike builds some awesome cars and engines, so when he told us he had something really cool to show us on the other side of the Indiana Convention Center during last year’s PRI Show, we eagerly met him there.

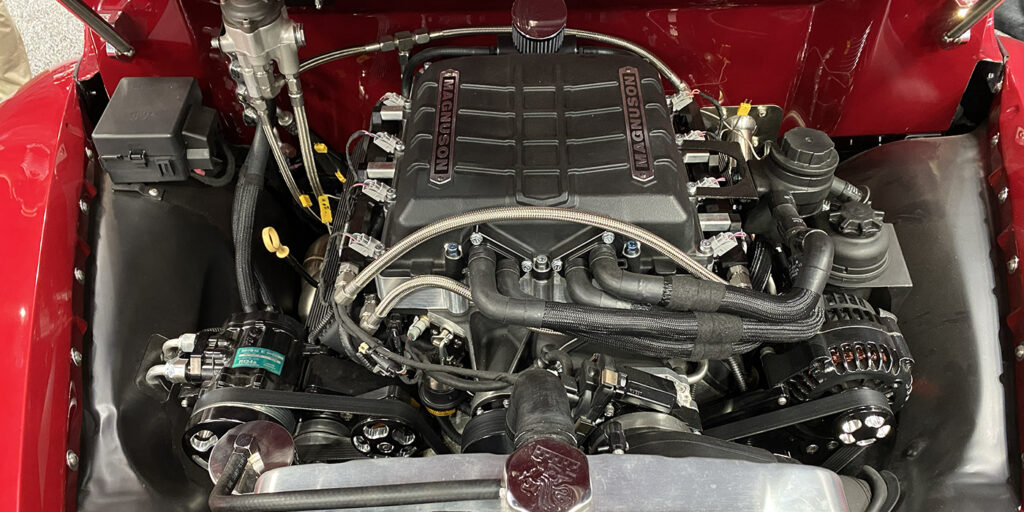

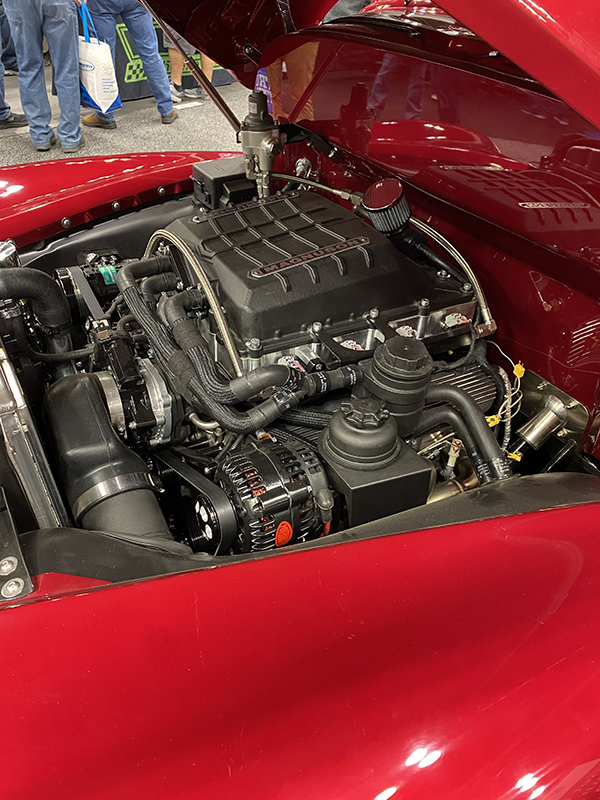

Sitting in the Eaton booth was a 1948 Chevy pickup truck, which in itself was truly breathtaking. Under the hood was a supercharged LS3 engine – nothing overly elaborate – especially for the floor of PRI, but it was outfitted to run on zero emissions with the help of hydrogen instead of gas! We were eager to know more about the project, and Mike was happy to oblige.

It turned out that the ’48 Chevy truck belonged to Mike’s wife, and it needed some sprucing up at the same time that Copeland’s company, Diversified Creations, was about to do some R&D work with hydrogen-powered engines. The ’48 Chevy and it’s LS3 engine became the proof of concept.

“Technically, this truck belongs to my wife,” Copeland says. “This is actually a truck she’s been wanting for years. It sat on a hoist waiting to get time to work on it. Then, when we got to the point that it was time to do something, we had the opportunity to do the hydrogen program. Using her truck was a natural fit because we needed something kind of cool to attract attention.

“This is a ground-up build done by Diversified Creations. This is a 10-week build start to finish. It features a supercharged LS. It uses a Magnuson 2650. It runs exclusively on hydrogen. We run a gaseous hydrogen, which we store in a tank in the bed. We run 350 bar, which is 5,074 psi. We bring it to the front through military spec AN lines. Then, we regulate it down to about 110 psi. Then, we inject that through 16 injectors. There’s eight in the traditional location and eight more in an adapter that we machined that goes between the intercooler and the supercharger.”

The engine is LS3 based, as mentioned, and uses a production, brand-new LS3 block. Copeland added engine oil squirters, or piston squirters to the mix. He also used a K1 crank, K1 rods and Wiseco custom pistons to round out the rotating assembly.

“We actually run a shorter rod in order to run a larger piston to allow us to transfer more heat,” Copeland says. “That’s not necessary to run on hydrogen, but because we’re targeting a power level and because we have the potential to create a lot of heat, we added that safety factor in.”

The valvetrain begins with a pair of stock LS3 heads. Copeland changed the exhaust valves to Inconel and it’s running production rocker arms with a trunnion kit in them, which acts as more of a safety factor because Mike plans for this combo to run a long time.

“The camshaft is a custom grind that Arrington created,” he told us. “I’m not going share the specs, but I will tell you that we run a really wide center line because the hydrogen does not like revision into the intake. When you run a lot of overlap and a tight camshaft center line, it pushes some back into the intake and dilutes that, and with hydrogen, you don’t want to do that. We run a 122.5 center line, but have comparable lift and duration numbers in the same range as what you would see for a traditional LS engine.

“Our target is 500 horsepower. We’re working on that and sneaking up on it slowly. The biggest issue is just injector sizing. We just don’t have enough injector. We’ll get the 500 hp with this injector, but we’re pretty much going to use them up to get there. There’s more power potential, we just have to change the injector.”

According to Copeland, the engine is 9:1 compression and runs on just 15-lbs. of boost with zero detonation. Therefore, there’s a lot of opportunity to add boost and to do other things with this kind of package.

“The unique thing about hydrogen is that hydrogen has the potential to create a lot more heat,” he says. “It contains three times the energy of gasoline and burns three times as fast as gasoline.

The real advantage to hydrogen is when you burn it, the only output is water. A minuscule amount of N2O and water. There’s no carbon monoxide. There’s no hydrocarbons. This is a zero-emission vehicle, but it still sounds like a V8 and still drives like a V8. It’s just running with zero emissions.”

The 1948 Chevy not only features the supercharged LS3 engine, but a Mcleod single-disc clutch, a Tremec TKX five-speed transmission, a 9-inch Ford rear axle from Moser, and an Eaton Truetrac. The doors, hood and cab of the truck are original, but everything else is aftermarket.

“If you know anything about aftermarket sheet metal, you know what we had to do to get the fit and finish on it,” Copeland says. “The paint is called passion red pearl.”

This is one truck that Mike and his wife love driving around. And, hopefully the hydrogen technology keeps V8 engines progressing into the future of zero emissions.

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Engine & Performance Warehouse Inc./NPW Companies. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].