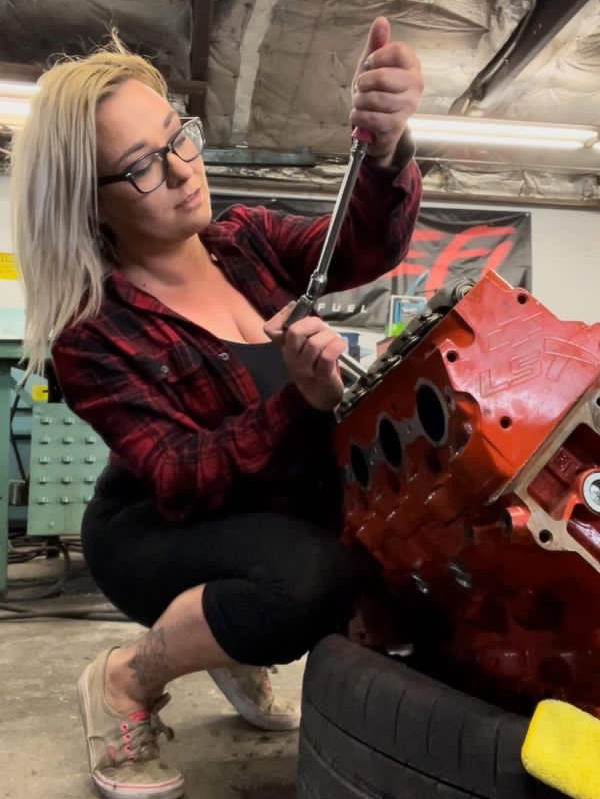

The vast majority of folks in our industry have been living, breathing, eating, and sleeping cars and engines their whole lives. It’s an industry that can be hard to break into for that reason. However, those of us who find this industry later in life, tend to have just as much passion for it. That’s certainly the case for Jillian McLaughlin, an engine builder at Precision Machine Engine in North Highlands, CA, just outside of Sacramento.

“I was never into this stuff growing up,” McLaughlin says. “I used to be a hairdresser out of high school.”

The turning point was meeting her husband Joe, who happens to own Precision Machine Engine, which is just as the name implies, an engine machine shop. Together, Jillian and Joe have six kids – four biological – and it was during one of Jillian’s pregnancies that she decided to help out at the engine shop.

“I used to do desk work and reception at the salon before I did hair, so I just started doing book work and working on the computer at the shop and I slowly started getting interested in it,” she says. “Joe is so into this scene that I’ve picked up stuff about cars through him. I didn’t know anything before meeting him. It was like a whole new life for me, but I fell in love with it pretty quick.

“I did hair, so I’ve always been a very hands-on type of learner. We had some people come in and train me, and at first, I started tearing down engines and learning all the different parts. I slowly started working my way up in the shop and learning more and more and more. I still have tons and tons to learn, but here I am. I started getting more into it the first time I saw a set of heads I built go down the track and the customer won the whole event. Knowing I was part of that was so cool and satisfying.”

Precision Machine Engine was founded a number of years ago by a different owner. Joe purchased the shop about six years ago and has been in business ever since building custom engines and race engines. Just as the shop has grown, so too has Jillian’s experience and capabilities around engines.

“What’s been really cool is having a lot of support and people who are willing to teach you in a way that you learn,” McLaughlin says. “I started just tearing engines down, learning all that stuff, and then I started doing heads more because that’s where we needed more help at the shop at the time. Once I started getting pretty good and comfortable with that, we just slowly started introducing more things.

“Now, I more do piston and rod balancing, assembling and gapping rings. I like that stuff a lot because it’s pretty rhythmic. When I know I have to do that I can just go turn my music on and get to work and just focus. For me it’s a very natural process.”

Jillian also keeps some of her engine jobs fun through social media. If you check out the Precision Machine Engine Instagram page, you’ll find plenty of cool videos of Jillian doing her thing, often in time lapse.

“I do a lot of the social media for Instagram,” she says. “That’s a whole other animal and a whole other job, but it’s fun. It keeps things motivated at the shop and gets everybody excited.”

Although her skills have continued to improve and Jillian has taken on more engine building jobs within the shop, she says that machine work is still something out of her league.

“I’m just not a big fan of machining because I feel it’s almost too much pressure for me,” she admits. “You can’t put the material back on and I don’t want to be the one to screw that up. I let everybody else handle that part. That said, I’d like to get more hands-on in the full assembly of the blocks. I know how to fully assemble heads and do the top end, but the bottom end, besides assembling the pistons, that’s something I’d like to learn next. There’s always room to grow and learn.”

When it comes to Jillian’s favorite engines to work on, she’s much like everybody else recently in that the LS engine is top-of-mind.

“I like LS engines because I know them the best,” she says. “We do a lot of big block Fords and big block Chevys too, but the LS is probably the fastest and easiest to get together and probably easiest to make the most power out of.”

Now that Jillian has been in the engine building industry for several years and gotten to experience engine shop life, she says it’s not always the easiest atmosphere for a woman, but overall, it’s been a very positive experience.

“I’ve had a good experience, but that’s because of the team around me and the people around me,” McLaughlin says. “It’s kind of funny when people say stuff about a girl working at the shop because they don’t know me and they don’t know what I know. It doesn’t really affect me. I actually think some of the jokes/comments are funny, which I’m sure not everyone would find funny, but my favorite one so far was a social media comment that said, ‘That’s a funny kitchen she’s in.’

“Everybody has opinions and we just get done what we’ve got get done and our engine work speaks for itself. As long as we put out the best product we can then it is what it is. If people don’t like that a woman is building their stuff, well, we can pretend I didn’t do it. Nobody’s going to know when it’s in your car.”

What might be even more impressive than Jillian’s jump into engine building is her ability to juggle her shop life with her home life, which includes those six kids mentioned earlier.

“They’re all 10 and under,” she says laughing. “It’s a lot, but Joe and I are a good team. We get it done. I’ll take a couple with me. He’ll take a couple with him. We’ve got some in school. It’s definitely a lot of balancing and it’s a lot of hard work, but it is nice because the kids see how hard we work and they know how hard we work. All the kids want to help, and they’re developing a good work ethic out of it at the very least. They’re seeing what it takes and they’re already telling us, “I want to own a business when I’m older,’ or ‘Do I get to work at the shop when I grow up?’ It seems to be working.”

Whether Jillian is working hard in the shop, enjoying some racing at Sacramento Raceway or Sonoma Raceway, or balancing her work and home life with her kids, she’s excited to call herself an engine builder and is looking forward to what the future of Precision Machine Engine has in store.