Engine of the Week is presented by

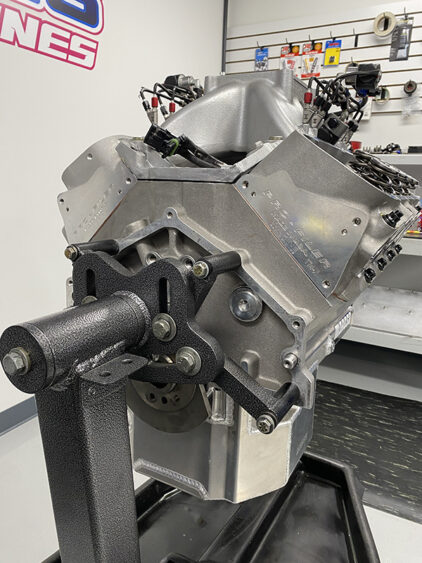

During our summer road trip to the Mooresville, NC and Charlotte area, we got the chance to visit with a number of amazing engine and machine shops. We didn’t schedule time to visit Wilkins Racing Engines while we were there, frankly, because we weren’t familiar with the shop. However, after we drove by the shop a couple of times during our stay, we were compelled to pop inside and see what was what.

We were greeted by owner Sandy Wilkins, who was kind enough to let us in to see what is truly a state-of-the-art engine shop. We were blown away with how clean and organized the shop space was, as well as the caliber of the race engines his shop specialized in.

We came to learn that Sandy is a Wilmington, NC native, who started racing at the early age of 14 with the World Karting Association’s dirt track series. He proceeded to sports car racing with the SCCA at the age of 15, and was state champion after his first year of competition. During his years at NC State University, Sandy was a crew member for Kenneth Trippy Pro Modified Bad Medicine Willy’s, as well as crew chief for his father’s sports car racing.

After graduating college in 1992, Sandy went to work for NASCAR engine builder Charlie Long. He continued to work with the Tripp’s, his father, and Charlie, while systematically building his own drag racing operation, and working his way up to Top Sportsman competition.

Drag racing competition eventually led Sandy to open his own engine building facility in Raleigh, NC. Wilkins Motorsports Racing Engines (WMRE) started in 2006 and was an overnight success. With multiple wins, national records and championships Sandy was soon approached by Roush Yates Engines to head up their new drag racing program. In 2010, WMRE was closed and Sandy became the Drag Racing Program Manager at Roush Yates Performance Engine Group.

After roughly a decade at Roush Yates Performance, Sandy had the itch to work for himself again, and opened Wilkins Racing Engines a few years ago in Mooresville, NC. When we popped into the shop, Sandy had a number of engines in various degrees of completion, but it was a 632 cid big block Chevy nitrous engine that caught our eye. He was willing to give us the full details of the build.

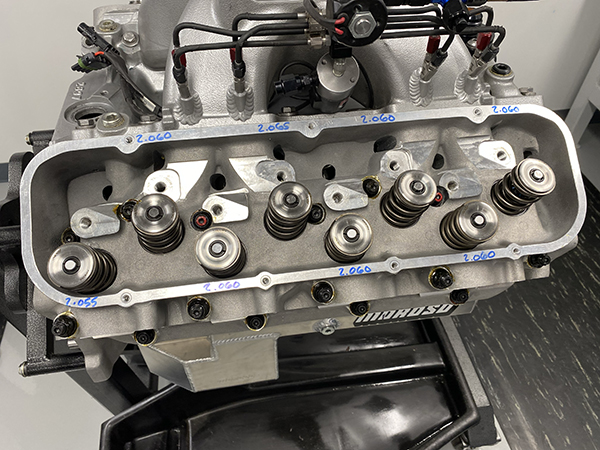

“This is a new customer to us,” Wilkins told us. “We take in new customers all year. One of our fortes is we work on stuff other people don’t want to work on. That said, this is a pretty normal deal. It’s a big block Chevy, 632 cubic inches, features a Callies crank, GRP aluminum rods, Diamond pistons, Pro-Filer CNC-ported conventional-style cylinder heads, and it should make, normally aspirated, in the 1,150 horsepower range. On the one system of Induction Solutions nitrous that the customer runs, horsepower should be in the range of 1,500-1,600 hp, depending on how much he wants to spray.”

According to Sandy, his customer races in No Prep-style drag racing. Sometimes it’s a back half of the track kind of thing, and sometimes it’s the front half no prep, but they have a ‘69 Camaro that this big block Chevy engine will wind up in.

The base of the 632 big block is a Brodix block that is half filled for added strength and stiffness in the cylinder area. The block also has steel caps and a larger cam core to benefit the engine making high horsepower.

“Almost all the engines we get from Brodix, the blocks are half filled,” he says. “We do that because the majority of these are going in drag racing applications, so the cooling is sort of less important than the stiffness. We really like the stiffness for the ring seal. This engine uses an .043”, .043” 3mm ring package, and it is a tool steel ring, and they just seem to work and last a lot better when you have the half-filled block.”

An interesting aspect of this build is that Sandy opted to go with a wet sump oiling system over a dry sump system, and he did so for a few reasons.

“The majority of our engines are dry sump applications, but this particular combination car, the wet sump suits better,” Wilkins pointed out. “With today’s Moroso-style oil pump and pan, you can have a very reliable wet sump engine that makes lots of power. We also choose the aluminum oil pan on every application because it helps with heat dissipation and getting the heat out of the oil. It’s not normally a problem until you get hot lapping towards the end of the weekend. Between round one and round two, the oil temperature cools down pretty good on its own, but the aluminum oil pan really helps get rid of the oil temp as you hot lap and are making passes quicker.”

Clearly, the big block Chevy has a stout bottom end, and that quality carries through to the valvetrain and cylinder head area as well.

“The Pro-Filer conventional heads are paired with a Jesel rocker system,” he says. “We use either Jesel or T&D. The majority of all of our engines are shaft rocker systems and that’s good for reliability and power. This particular engine has all stainless valves because we wanted to keep the cost down, but in an all-out application we’d be using the titanium valve and the steel rocker.

“Our camshaft is a 55mm. It has a standard cam height. Most of the 632s we do are raised cams, but once again, because of the application and what he was trying to do and keeping the cost a little bit down, we chose the 55mm cam and that way we can use the standard cam height belt drive and parts that are a little bit less expensive. Up top, we have an Edelbrock manifold that we really like for its performance normally aspirated.”

Despite keeping costs down in some areas, this 632 big block Chevy nitrous engine has quality components throughout, and it’s an engine that got machined and built extremely well to the tune of 1,150 horsepower NA and 1,500-1,600 horsepower on nitrous. It just one of many examples of the kinds of engines being built at Wilkins Racing Engines.

Engine of the Week is sponsored by PennGrade1, Elring – Das Original and NPW Companies. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].