Engine of the Week is presented by

A gearhead through and through for as long as he can remember, Justin McLendon was always elbow deep working on something automotive related. From engine building to car modifications, Justin grew up in the automotive industry and knew from a young age he would make a career of working on cars.

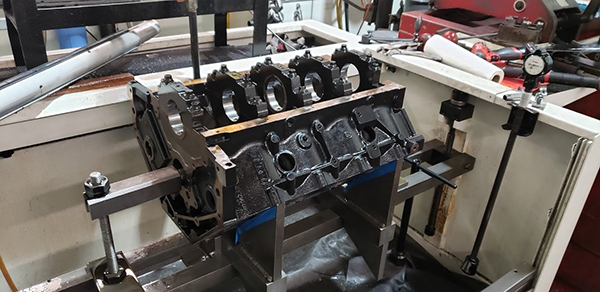

“From a young age, I can remember reading the results of Engine Masters with my dad and we would talk about some of the strategies that some of the entrants had utilized,” McLendon says. “The idea of pushing the envelope, trying to find the gray areas of rules and apply outside-of-the-box thinking to result in horsepower has always fascinated me. I guess that’s why competitions such as Engine Masters have always had my attention.”

As Justin kept up with Engine Masters Challenges and grew his collection of car magazines, the School of Automotive Machinists and Technology, located in Houston, was a name very familiar to him. Justin knew he wanted to meet the likes of Jud and Linda Massingill someday and experience their passion for the motorsports industry.

“In 2014, I had attended LS Fest with my 1990 C1500 I had built from the ground up with the help of family and friends,” McLendon says. “It was at that event that I was approached by a member of SAM Tech’s admissions department who saw my truck and basically told me I would be a good fit for their program. To say the least, I was flattered, but I had other plans, or so I thought.

“I was leaving the Air Force in December 2015 and had already made up my mind that I was going to go into mechanical engineering at a university near my home town. The closer I got towards actually leaving the military, the idea of going to SAM Tech as a means to transition to civilian life was sounding like the best course of action. I had decided that I would take their CNC course, the plan being to utilize that course to get a decent part-time job while I attend university for mechanical engineering.”

Fast forward to 2018, Justin was a senior mechanical engineering student who was burning himself out with 16 to 20-hour semesters, while also working as a computer draftsman at an industrial machine shop.

“I needed a breath of fresh air, and I was not able to shake the feeling of how nice my experience was at SAM Tech,” he says. “It had occurred to me then I just needed to take the plunge and take my so-called ‘sabbatical’ at SAM Tech for a couple years.”

Justin is currently SAM Tech’s orientation instructor, where his job is to take in students from all walks of life and prepare them for their core classes, which includes making sure the students have proper comprehension of the math and theory, as well as the basics of the machining processes used in the industry.

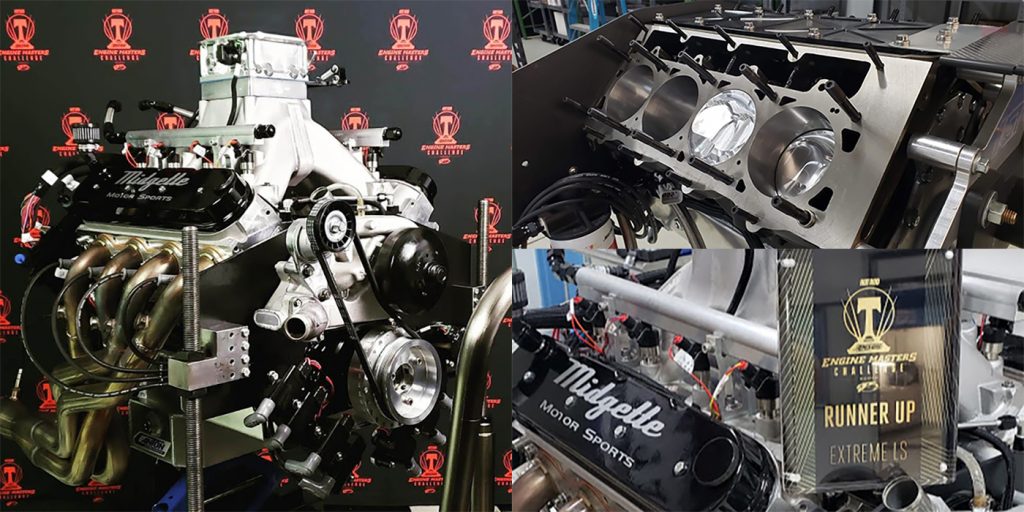

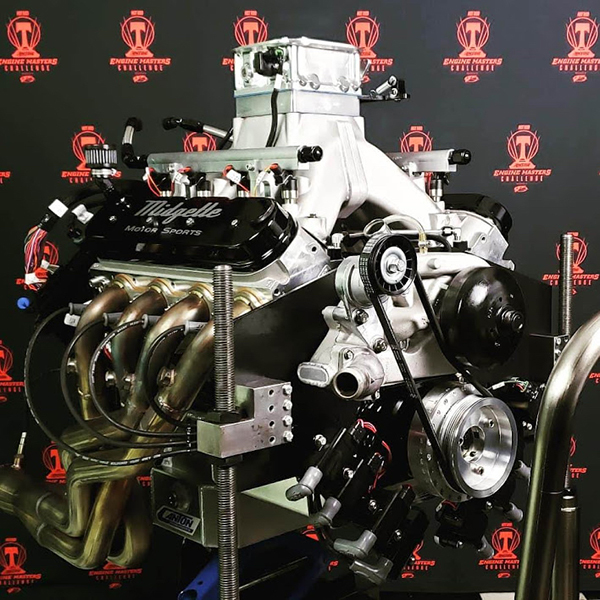

To give SAM Tech graduate students a taste of the real engine builder life, Justin recently brought a group together to build a 439 cid LS7 engine to enter into the 2019 Engine Masters Challenge Extreme LS class.

“As a student and part-time instructor at SAM Tech, I decided to take on this project to showcase what I have learned and build my resume,” McLendon says. “This has given me a unique appreciation for all the different aspects that are involved with the process of producing an engine. I enjoy trying to solve the puzzle of ensuring all the right components are chosen for an engine in a given application. I also used the engine as a means of instruction in my classes throughout the year. This gave students a unique chance to be involved with an Engine Masters build and the theories of how to accomplish the task. I did have lots of help from the students and three graduates in particular – Tyler Fearon, Matthew Midgette (Midgette Motor Sports) and Derreck Kelly.”

To build this LS7 engine, Justin was given the ability to utilize the equipment at SAM Tech as needed to complete the project. For the Engine Masters competition, he chose to enter the Extreme LS class in order to go up against top-notch builders and for the freedom of the rules in that class.

“Aside from displacement, valve angle, carb/TB spacer limitations, and header restrictions, this class had virtually nothing to limit us,” he says. “This actually made our job more difficult because freedom within the rules meant we had to anticipate what others might bring to the table. This class also had the largest rpm pull range of any class of any year in the history of this competition.”

The scored range was from 3,500-8,000, with the pull starting at 3,200 rpm and ending at 8,100 rpm. This made things such as camshaft selection and compression ratio very difficult.

“Our objective was to go into this competition and make a bold statement,” McLendon says. “We knew there would be some recognition, being that we were a young team competing against names that were staples in the industry. However, I wanted to make sure we put an entry out there that would be respectable and speak for itself.”

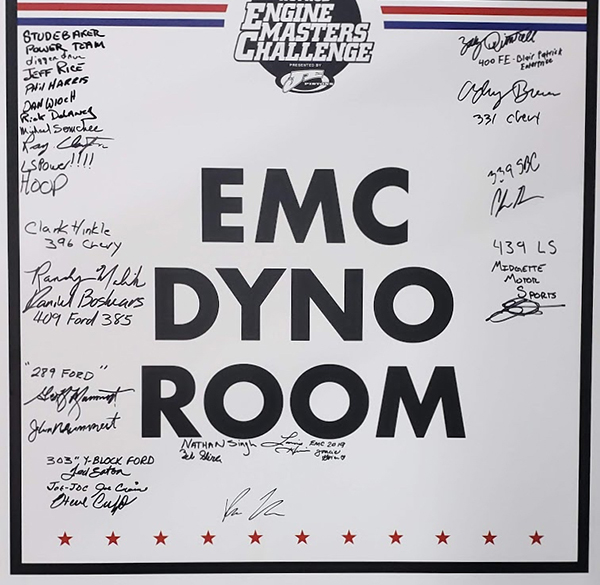

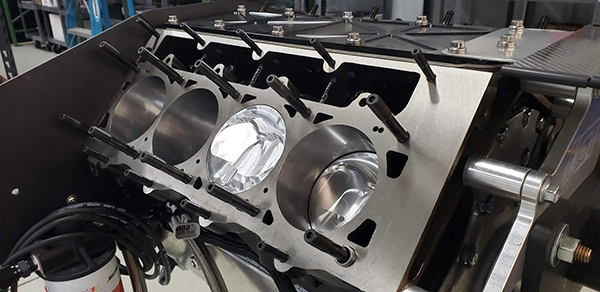

Before the LS7 build even got to the machining process and parts selection, there were a couple attributes Justin wanted to utilize with this engine combination. First, he wanted to go with the smallest bore (4.125) before sacrificing airflow with the LS7-style cylinder head and go with the largest stroke (4.100) possible to meet max cubic inch allowed. Secondly, he wanted to utilize the lightest weight rotating assembly he could to hold the expected power.

To kick off the build, Justin chose a Dart LS Next block for its revised oiling system with features such as crossover oiling for the lifters and skirtless design. Inside, the block was finished out, cartridge rolled and then an oil shed coating was applied internally. The main clearances were .0024˝-.0025˝.

“Our crankshaft was 4.100˝ and highly modified,” McLendon says. “The crankshaft we had ordered hit a production snag and we weren’t able to receive the desired crankshaft in enough time. Due to the fact that I already had the rest of the rotating assembly in hand, I had to get whatever crankshaft I could and modify to what I had spec’d out previously.

“I started with an offshore forged crank with 4˝ stroke and standard rod journals set up for a 1830 bobweight. From there I had the crank offset ground from 4.000 to 4.100˝ stroke, and from a standard rod journal of 2.100˝ to a 1.888˝ journal. To get the crank to cooperate with the 1500 bobweight, I had to take quite a bit of material out of the counterweights. I spent quite a bit of time on the lathe to take the material out radially to eliminate the need to drill multiple holes. I also was able to use this time to reshape the leading edges of the counterweights with a flap disk on a grinder. Between the grinder and the lathe, I didn’t have to drill any additional holes in the counterweights to get our desired final balance.”

The connecting rods were 6.125˝ Molnar SBC lightweight rods with Honda journals and .927˝ pins.

“The small end of the rod was modified to have the same center line as the journal end,” he says. “The connecting rods were coated in a heat-repellent coating that doubled as an oil shed. On the journal side our main clearances were .0018˝-.0019˝, and our pin side measurement was .0008˝.”

For the pistons, Justin worked with SAM Tech graduate Travis Bieber and CP-Carrillo to create custom, 4.125˝ pistons with Total Seal piston rings. Trend Performance supplied DLC-coated wristpins and wire locks, and the bearings were from Clevite.

“For the cylinder heads, we started with an on-the-shelf Brodix STS BR 7 BS 273, then touched up a couple of places that made the cylinder head perform a little better for our style of competition,” he says. “The camshaft was a custom ground solid roller unit from Cam Motion with a standard LS 55mm journal diameter and 242/256 duration.”

The LS7 build also utilized Crower rocker arms designed specifically for the BR7 heads, Trend double taper 3/8ths pushrods, Morel solid roller .903˝ lifters with a modified oil circuit for better lubrication, PAC springs and retainers, and Xceldyne titanium valves.

“I designed the lifter bushings to provide proper oiling with high lift as the Dart block sometimes has issues with lightened lifters,” he says. “The bushings also doubled as restrictors.”

For the oiling system, Justin turned to a Melling Select, standard volume, standard pressure oil pump, a Canton oil pan and a modified racing windage tray.

On the intake, the LS7 got equipped with a CID 4.5 LS7 manifold that was port matched to the cylinder heads and to a large, dual-bladed 4500 Holley throttle body.

To finish out the build, Justin used American Racing Headers’ COPO headers, an Innovators West LSX 6.75˝ racing balancer, a Holley HP engine management system, 48-lb./hr. injectors and a 13.8:1 compression ratio. Unfortunately, the finished engine didn’t perform as desired.

“We actually encountered a couple of road blocks, though not unlike most builds of this type,” McLendon admits. “Outside of the crankshaft, we hit another road block which hurt our engine and almost prevented us from being able to show up to the competition. We had an injector stick open on the #3 cylinder and caused a multitude of issues from there.

“With the fuel injector stuck open on cylinder #3, it washed the cylinder down. Cylinder #3 ended up hydro-locking and breaking our crankshaft and destroyed a few bearings. If that crank hadn’t broken, who knows what else would’ve broke on our engine.

“In the end, I feel absolutely lucky that we showed up with an engine we knew was hurt (albeit not knowing how extensive the damage was) and made the power that we did.”

At the 2019 Engine Masters Challenge, Justin’s 439 cid LS7 made 697 hp @ 6,800 rpm and 578 ft.-lbs. of torque at 5,600 rpm. During testing ahead of the competition, the engine made 800 hp and 675 ft.-lbs. of torque.

“Even though we showed up with a hurt engine that wasn’t firing on all 8 cylinders, I feel we made a worthy statement and were happy to have made it there at all given the obstacles that tried to prevent us from showing up,” McLendon says.

Moving forward, Justin says he isn’t finished with this LS7 build. He says it probably isn’t a fit for the new 2020 Masters of Motors Dyno Competition, but it should be well-suited for the 2020 Race Engine Challenge Max Street class, so stayed tuned for more LS7 power later this year!

Engine of the Week is sponsored by PennGrade Motor Oil and Elring – Das Original.

If you have an engine you’d like to highlight in this series, please email Engine Builder Editor, Greg Jones at [email protected].