The pump gasoline sold at gas stations around the country has changed quite a bit over the last several decades.

The first major change was the removal of lead from the gasoline. The next major change was to reformulate the gasoline to reduce both the evaporative and exhaust emissions from vehicles. Then, the federal government mandated the use of oxygenation of gasoline in many parts of the countr y. The latest method to oxygenate the fuel is with ethanol made from corn.

y. The latest method to oxygenate the fuel is with ethanol made from corn.

These recent changes in gasoline formulation may or may not be a good idea in theory, but since this modern gasoline contains less energy than it did in the past it may actually cause a loss in power, fuel efficiency and driveability unless the engine is properly tuned for these new blends of gasoline.

Gasoline with Ethanol

The addition of ethanol to the gasoline is causing problems with many fuel system components of in a vehicle’s fuel system that was not designed with ethanol in mind. Ethanol is very corrosive to many of the materials that were commonly used in fuel system of older vehicles.

Ethanol can also act as a solvent that will attack any component made with plastic or rubber compounds (such as the fuel hoses) that it comes into contact with, also components made from brass, copper and aluminum can become corroded over time if they are not given proper surface treatments.

Heat is also a factor to consider in how quickly the rubber and plastic compounds used in the fuel system will degrade with the exposure to the fuel because the rate of reaction doubles for every 10°C rise in temperature.

Ethanol is also a hygroscopic substance that readily attracts water from its surroundings such as the moisture that is in the air in the fuel tank, it takes as little as one tablespoon of water per gallon of gasoline to cause the ethanol to phase separate from the gasoline.

When the ethanol and water mixture phase separates from the gasoline it will drop to the bottom of the fuel tank.

This phase separated ethanol and water mixture is extremely corrosive to anything it comes into contact with. Plus, it will also cause engine performance/drivability problems as it flows into the engine through the carburetor or fuel injectors.

Modern Gasoline and Vintage Engines

A 1997 or newer fuel injected vehicle has an ECU/PCM (computer) that should be able to make the necessary air/fuel mixture and ignition spark timing adjustments necessary for gasoline with up to a 10% ethanol mixture.

Most vehicles manufactured after 2005 should be able to handle up to 15% ethanol content in the gasoline, but older vehicles will begin to experience performance issues with the higher ethanol content in the gasoline. The vehicles that are most effected by the addition of ethanol to the gasoline are the older carburetor equipped engines which will need to have their air/fuel mixture and ignition spark advance curves retuned for these new blends of “cleaner burning” gasoline if they are expected to perform their best.

The ethanol content of gasoline will cause the air/fuel mixture of a non-computer controlled carburetor engine to shift leaner, which will often cause a loss in driveability and throttle response. These new blends of reformulated gasoline (with and without ethanol) are actually quite different from the leaded gasoline that a vintage carburetor equipped engine was designed and tuned to use.

The main differences between today’s gasoline and the leaded gasoline of days past are the burn time of the fuel and the distillation profile of the fuel, but it actually goes deeper than that. The composition of today’s gasoline is very different when compared to the leaded gasoline of the ’60s because of the removal of lead, the addition of ethanol and the modern fuel additives that are in the fuel.

Tuning a Vintage Engine for Modern Gasoline

It’s important to understand that the modern, fuel-injected, computer-controlled engine is a very different animal than the carbureted engines of years past. The computer of a modern, fuel-injected engine continually adjusts fuel and spark to adapt the engine to today’s ethanol and reformulated gasoline blends.

A vintage carburetor equipped engine simply cannot do this by itself, therefore you will have to retune the carburetor and distributor for these new blends of gasoline. If your customer is experiencing driveability and throttle response issues with a vintage carburetor-equipped engine the problem may be caused by the changes in today’s reformulated gasoline with the cure being to tune the ignition spark advance and air/fuel curves for the modern fuel blends of today.

Ignition System Tuning

Most modern fuel injected engines have a computer – controlled ignition system that has been programed with a spark advance curve suited for today’s gasoline, plus it provides the spark plug with the higher current and longer duration spark that is needed to prevent misfire problems. But the ignition system that most carburetor- equipped engines came with can prove to be marginal with today’s reformulated gas blends.

Today’s gasoline burns somewhat faster than the leaded gas of days past, but it needs a hotter spark to ignite it. The ignition spark advance curve that is programmed into the PCM of a typical modern fuel-injected domestic V8 engine would also work quite well with a vintage carburetor- equipped engine.

A typical vintage Ford or Chevy small block (with a mild camshaft) will perform well with a spark advance curve that has 12 degrees initial timing plus 24 degrees of

mechanical advance all in by 3,600 rpm with an additional 10 to 12 degrees from the vacuum advance.

Fuel System Tune-Up

The changes in the formulation of today’s gasoline most often causes a carburetor to shift about 3 to 5 percent leaner than the gasoline most carbureted engines were designed and tuned to use.

The most common problems we see with carburetor-equipped engines are lean off-idle surge/misfire complaints and poor throttle response complaints.

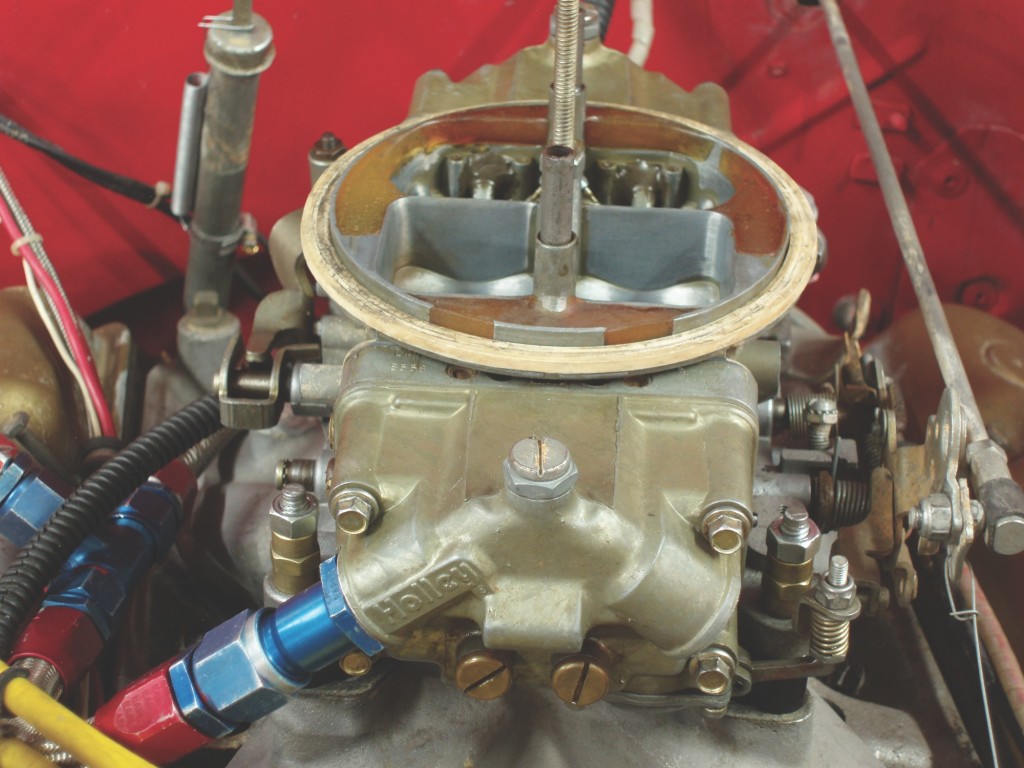

The tuning changes needed to cure the lean off –idle problem involves enriching the off-idle circuit through enlarging the idle well of a Holley-style modular carburetor or enlarging the idle channel restrictor (ICR) of the Rochester carburetors or the Carter AFB and AVS carburetors (including the Edelbrock Performer and Thunder series carburetors). The throttle response issue is often cured by making the accelerator pump circuit more active by increasing the strength of the accelerator pump duration spring and sometimes enlarging the accelerator pump squirter size.

Most of the high performance replacement carburetors built after the late ’70s have an accelerator pump duration spring that is not as strong as the original spring strength that the carburetor was originally designed to have.

If you are rebuilding an engine for vintage carburetor-equipped application you may want be sure your customer is aware that they will need to retune the ignition spark timing curves and the air/fuel mixture curves of the carburetor, plus the fuel can create swelling problems with the rubber (elastomer) and plastic parts that are common in a carburetor equipped engine such as the rubber gas hoses, the accelerator pump and a nitrophyl carburetor float.

Both ethanol and the aromatics that are in gasoline (such as benzene, toluene, and xylene) have also been shown to have negative effects on parts that are made with rubber and plastics.

The gasoline sold today also may have a higher level of aromatics than the gasoline that was sold decades ago. The combination of ethanol and a higher aromatic level in the gasoline may increase the rubber and plastic swelling problems more than if the fuel had just ethanol or just high aromatic levels.

The exposure of any fuel system components made with rubber or plastics to high heat conditions (including the normal under hood heat conditions after an engine is shut off) and today’s reformulated gasoline will also accelerate the rate that the fuel will attack the rubber and plastic components it comes into contact with.

The best way to help prevent these problems is to keep fuel hoses away from any heat sources and to use a heat insulating spacer under the carburetor.

Vapor Lock Volatility

The ability of a fuel to vaporize or change from liquid to vapor is referred to as its volatility. Volatility is an extremely important characteristic of gasoline because an engine can only burn the vaporized portions of the gasoline.

Depending on the time of the year and local regulations, ten percent of the fuel should be evaporated when the temperature reaches the 122°F to 158°F range, 50 percent of the fuel should be evaporated when the temperature reaches the 170°F to 250°F range and 90 percent of the fuel should be evaporated when the temperature reaches the 365°F to 374°F range.

The easiest and safest way to measure the volatility of gasoline is the Reid vapor pressure (RVP) method, which measures the absolute vapor pressure exerted by the gasoline at 100 °F. The RVP has changed from as high as 14 lbs. in the 1960s to where it is currently, which is as low as 7.2 lbs. in California during the summer months.

The under hood temperature of many vehicles will reach 230°F or higher during a hot soak (after the engine is shut off) so 50% of the gasoline (the most volatile parts of the fuel) in the carburetor may boil off. This heating and subsequent boil off of fuel components can and does wreak havoc on fuel curves and ignition timing requirements of a carburetor equipped engine plus it will create vapor lock issues if the gasoline boils in fuel lines or the carburetor bowl(s). The answer, particularly in a carbureted engine, is to minimize the exposure of fuel system components to heat in every way possible.

Aging Gasoline

The gasoline your customer buys at their local station has a shelf-life that can vary from 90 days to at least one year from the day it was blended,

depending on how it is stored. Most gasoline made for the general public is consumed within 30 days of being blended but the slower selling premium grades of gasoline sell at a much slower rate than regular grade gasoline.

Premium grade gasoline makes up less than 5% of the gasoline sales at some gas stations therefore it is possible that it may be less than fresh if you buy it at the wrong gas station. It would be wise to advise your customer to be sure the gasoline they have in the fuel tank of their vehicle is fresh before they try to start the

engine you just built for them.

The last thing any engine builder wants to have happen is to have the engine they just built have any problems caused by bad gasoline.

Whenever gasoline is exposed to heat, moisture, air or light it will begin to go bad, as the gasoline ages the most highly volatile components in gasoline tend to evaporate out through any vent in the tank. It will also degrade with time and exposure to the elements.

As the gasoline ages, it will become less volatile, which will cause the engine to be hard to start plus it will also cause the engine to produce less power. The use of this degraded fuel may be one of the worst things to which you could expose an engine that you just rebuilt to.

When gasoline is stored for an extended period of time, it will gradually turn into a varnish-like substance that if used, will raise havoc with both a fuel-injected or carburetor-equipped fuel system.

The gasoline tank of most modern fuel injected vehicles is sealed, thus its exposure to outside air and moisture is limited but you still have the heat issue to consider.

Most vehicles built before 1970 have vented gas tanks, therefore the fuel in these tanks will degrade at a much higher rate than a vehicle with a non-vented gas tank. This is because the fuel is exposed to the outside air that contains moisture that enters through the fuel tank’s vents and venting to atmosphere can allow some of the lighter/more volatile portions of the gasoline to escape.

Extending Gas ‘Shelf Life’

If you can, it would be wise to advise your customer to add a gasoline storage stabilizer to the fuel tank if the

vehicle will not be driven for any extended period of time. This is even more important in a vehicle that has a vented fuel tank because there is a constant source of fresh oxygen that will cause the gasoline to degrade at an accelerated rate.

In addition, the use of an ethanol treatment product contains increased water handling additives that will help a stored vehicle handle the excess water that tends to build up in an open vented system. Ethanol treatments also have enhanced corrosion inhibitors that will help protect the metal portions of the fuel system from corrosion that is caused by any water/ethanol blend that may develop over time in a fuel tank.