Finding Performance Potential in 4 and 6 Cylinder Engines

Let’s get something on the table right now – I’m a V8 guy. As you’ve read elsewhere in this issue, I tend to also chant the mantra, “There’s no replacement for displacement.” Bigger just seems better and badder. Perhaps you’re like me.

But let’s take a few minutes to put our prejudices aside, overcome our ignorance and look at whether the small engines out there offer profit potential to engine builders, machine shops and parts salespeople.

Small engines are nothing new. Four and 6-cylinder engines have been (and continue to be) popular in many cars and, indeed, racing series. There was a time when adding horsepower to your in-line 6 was natural, but that seems almost forgotten today. Many a 235 Chevy “Stovebolt” got its exhaust manifolds split, a Fenton manifold and multiple carburetion.

I remember when the old Chrysler performance catalog had factory performance parts for the slant-6 225. Chrysler even made a long tube ram 4-barrel intake manifold for the old 6s. If we were in Australia, we’d know and appreciate the 245 cid inline Hemi version of the slant-6.

Back to the land-down-under, you can also find performance straight six Ford engines. A much nicer cylinder head was available for the 200 cid motor that does not have an intregal manifold. Manifolds are available for multiple carburetion making these 7-main inline 6s something more akin to a European performance sedan engine. And much to my surprise, during my research I learned there is a company in the U.S. that copied that Aussie head and is making them and manifolds to match.

Anyone remember the Tijuana Taxi from the ’70s? A four-door Ford Maverick drag car that ran a full tilt 300 with a custom welded Cleveland head. If memory serves, it was made from three 2-cylinder chunks of 351 Cleveland heads furnace brazed together. Now that’s hotrodding!

Now, we’ve all had the customer who wants to get more power from his or her domestic 4 or 6-cylinder engine, from here on to be labeled “non-V8,” but was not planning a turbo or supercharger installation. So the search starts for non-V8 performance parts. Unless it’s a popular application like a 4.3L Chevy or 3.8L Buick, this is going to be a long search for a short list of parts. There are some performance listings for the old 2.3L SOHC Ford 4-banger, which are used for some class racing and maybe a short list of camshafts and manifolds for the Ford and Chevy 6s. From here on the majority of what you’ll find is for late-model turbo and supercharged engines and some bolt-on and dress-up parts for Fords and Chevys. There is one other domestic application that gets a lot of special parts attention as well, however.

The AMC-Chrysler-Jeep in-line 6 in the 242 and 258 cid, or 4.0L and 4.2L, versions have a good supply of parts available. And if you combine the two, in the form of a stroker, we can make a 4.6L super 6. Some time ago, some savvy parts guy figured out that you could assemble the big bore 4.0L block with a 4.2L long stroke crank and short rod attached to a 4.0L piston and the combo netted a big 4.6 liters. Camshafts, manifolds, cranks, rods and even aluminum cylinder heads are available for the old Rambler. With the huge popularity of the Jeep market today, it is no wonder suppliers are producing parts for this in-liner.

So what’s a builder to do if he gets a request to build one of the other 6s? Start hotrodding! Working on a 300 Ford? The pistons from a 390 Ford can be used to raise the compression ratio. Valve train won’t be so bad once you’ve taken some dimensions. Don’t forget to plan for some valve lift though. Many of these 6-cylinders have a long rocker arm with a big ratio.

For most engines you’ll be hand porting and installing larger valves to improve cylinder heads. There may be some factory race heads available for a few V6 applications, and even that’s going to take a lot of internet shopping and some good old fashioned networking to find. Same with those Aussie heads, but there is the aforementioned aluminum 200 Fords. While you’ve got the head off, it’s probably time to mill a bunch off to get that compression up.

Now that your head is flowing a little better, you’ll need a camshaft to hold those valves open higher and longer. If your cam is not available from a traditional grinder, the stock one can always be sent out and reground. This will affect the base circle and depending how much the head and block are decked, it’ll be anyone’s guess what pushrod length might be needed. It’s a good thing custom pushrods make this easy.

An idea I’ve been playing with involves solid lifters in one of these 7-main engines and some high rpm shifting. And who’s going to expect the sound coming from those noisy solids is attached to 6-cylinders and only 12-tappets? To push it further, maybe it’s time to fit some roller lifters – I was just speaking with an intrepid builder who was planning that very modification.

If we’re going to spin it, let’s not forget durability factors. Upgraded bearings may be available and some are shared with the V8s, or maybe you can find something by dimension to at least improve the rod bearings. Bolts can usually be found, but again it may take some measurements and a call or two to your supplier or a manufacturer. Connecting rods are listed in parts catalogs for many domestic V6 and some 4-cylinder applications, and seem to be very plentiful for the import applications. You’ll only find a couple of listings for domestic in-line 6s.

If we’re talking power improvements without boost, durability issues shouldn’t be as big a deal and stock parts may be perfectly adequate. But if you’re adding boost, they should definitely be addressed. This would also include studding the block and finding a MLS head gasket. Most of these engines only have 4-head bolts per cylinder, so good bolts or studs and the best head gasket you can find will be a must if you’re raising the compression ratio a lot or boosting the engine.

It’s fun to dream about a little “Dare to be Different” domestic project, but the sport compact owners have been doing it for years. Small import engines have become very much mainstream and even a part of the culture. I went over to my video library and grabbed a copy of “The Fast and Furious.” It was dated 2001. That doesn’t mark the official start date for import performance of course, but it’s a good marker of when things got serious nonetheless.

Although the SEMA Council serving this market has changed its name and mission a few times since then (from the Sport Compact Council to the Street Performance Council to the Emerging Trends and Technologies Network) the point that creativity is still part of this industry should be apparent and welcomed.

One thing we learned about the import, or sport compact market back then, that is still true today, is that the power for those small displacement engines comes from two things: boost and nitrous!

To make big horsepower from small cubic inches there really is no other way. At 1.4 hp per cubic inch a 2.2L or 134 cid engine is only going to make 187.6 hp. This engine would not be very drivable with all the power and torque coming on at a rpm that would be too high for normal street driving. Turbocharged, these things make 400 hp or more and are street or occasional drivers. The big Japanese 6-cylinder engines are making 700-800 hp. These are expensive builds, but very big power from small engines.

The 2.5L engine in the popular Surbaru WRX will be featured in an upcoming Labor Costing Survey in Engine Builder magazine. My WD counterparts say this is one of the most popular import engines in the aftermarket, although the import parts market pales in comparison to the domestic V8 engine parts market.

If we were to push the envelope on our domestic in-line 6 build and apply the same math, 250 cid makes 350 horsepower. That’s a tall order. But, add some boost on top of some good components and we might make a 2 hp per cubic inch engine. A 500 hp Chevy 6 sounds nuts. I’m also picturing a 300 Ford stuffed in a ’64 Falcon or early Mustang and the shocked look on the face of the guy who’s jaw just got mopped up when the hood was raised.

Besides Jeep motors, another place we still see a lot of in-line 4s and 6s is in marine applications. Every once in a while, I’ll hear from someone wanting to up the power in his or her 250 GM marine inboard. If I remember correctly, the last one I was involved with started by removing the 250 and replacing it with a truck 292. I think that one got decked and the head shaved for an honest 9:1 compression, a mid-range cam and some bigger valves. It seems like it should be able to pull two skiers up with no trouble at all.

Pulling more power and reliability from an engine is nothing new, and the science can be applied to just about anything. Using modern cam grinds, maybe a flow bench, heavy-duty aftermarket parts, boost and some good old hotrodding skills, we might even build something a little different from the belly button V8s that clutter most shops 365 days a year. Maybe we’ll see more like Don Groff’s 5.0L V12 Toyota that started life as two DOHC in-line 6s.

I’m hoping soon to be able to share an in-line 8 built by attaching two Quad IVs end-to-end, each running a turbo and electronic fuel injection, stuffed in the engine bay of an early ’50s Pontiac that started life with a straight-8. Talk about a sizeable diet and increase in power! We’re talking a good 500 hp on tap when those turbos spool up.

Sure, we can always buy or build motor mounts and go straight for the V8. But sometimes it’s more of a challenge to put that idea on the sideline and go with your in-line!

You know what else they say, size doesn’t matter.

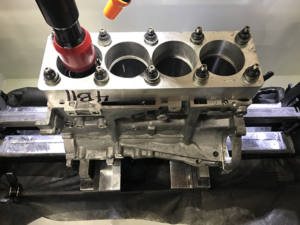

LD9 Oldsmobile Quad IV

Sometimes, customers just want different and their requests may seem crazy. Harold Norry, of Engines by Hal in Quelph, Ontario, Canada, says those weird requests often result in the best engines – and longstanding friendships.

The stock turbocharged LD9 in a customer’s Quad IV needed some serious attention to compete in the sport compact drag racing class. Block modifications to the old inline four improved the oiling characteristics and upgraded aftermarket components were used where possible, though Norry says there’s not a lot available for this engine anymore.

The camshafts are modified stock camshafts and the heads are stock cylinder heads with a five-angle valve job and custom hand porting.

The original LD9 was rated at 155 hp from GM; after Norry’s work it was making 156 hp – per cylinder. “One cylinder is making more horsepower now than the complete engine did stock,” Norry says. Additional upgrades have pushed the Quad IV to produce over 700 hp. That’s the kind of thing a good friendship is built on.

For the complete story, visit www.enginebuildermag.com/engine-of-the-week/

Nissan VR38 Twin Turbo

Mitchell Wilson of Engineered Performance in Alvarado, TX, credits social media for bringing him customers from across the city – and across the world.

A customer in Qatar who follows Wilson on Instagram was impressed enough with what he saw online to ship him the block and parts to build a 1,600 hp twin-turbo engine. Wilson says additional parts and services were needed to achieve – and exceed the goal – but the ease of communication across the world made the build relatively painless.

After boring and stroking the block to a 4.1L size, Wilson added performance aftermarket parts and employed a variety of coatings and treatment techniques. “We did all that because this car was destined to make 2,000 hp,” Wilson says.

Wilson’s customer participates in national racing events in Qatar. “The customer was really looking for about 1,600 hp to the tire,” Wilson says. “He actually made 1,620 hp to the tire. You do the equation for drive train loss and it came out to 1,945 hp, which is what it made at the crankshaft. So he hit his target and more.”

The twin-turbo Nissan put out 1,235 lb.-ft. of torque at 7,800 rpm.

For the complete story, visit www.enginebuildermag.com/engine-of-the-week/

Mazda Miata BP4W

Miatas are fun, peppy little cars that encourage drivers to smile. The BP4W Mazda engine built by Chris Graham of Race Engineering in Salisbury, NC, encourages more than that.

Graham upgraded the track car’s tired engine with new racing parts and the largest supercharger he could get for the Miata. “We’re running 14 pounds of boost with the current pulleys that are on the system now and we were able to more than double the horsepower in the drivetrain to the rear wheels than where it was at the factory. We increased by almost 55 percent when we upgraded the supercharger,” Graham says.

The Miata’s small air flow openings and such a huge supercharger meant underhood cooling issues required a new triple core radiator. “It’s doing well,” Graham says. “This car has plenty of horsepower to get some air moving through there!”

For the complete story, visit www.enginebuildermag.com/engine-of-the-week/

Nissan Twin-Turbo GT-R V6

Houston engine builder Mike Cogburn of CP Engines may specialize in late-model domestic builds but he has a soft spot for sport compact performance as well. This twin-turbo Nissan GT-R V6 is a fine example of how breaking out of your comfort zone can pay off in a big way.

His customer brought the damaged engine to Cogburn with the instruction to rebuild it so it would reach 2,500 hp.

With a new billet crank, aluminum rods and custom pistons as well as a dry sump and mechanical drag racing fuel pump and new, stronger top end components, the engine utilizes two modified 76mm turbos. With its 11:1 compression ratio and running on E98 fuel, Cogburn says the GT-R has exceeded his customer’s expectations.

For the complete story, visit www.enginebuildermag.com/engine-of-the-week/

Mitsubishi EVO 4B11

According to parts experts, the Mitsubishi Evolution is one of the aftermarket’s most popular cars for engine upgrades. Howard Anderson of AR Fabrication in Winchester, VA, is perfectly fine with that.

Anderson says lead times of 8-10 months don’t stop customers from presenting their challenges to him and the 4B11 Evo has been a great part of his business. The OEM sleeves are prone to cracking at higher boost levels and pistons fail due to improper tuning.

As a full-service machine shop and engine assembly facility, Wilson says he builds for several installation shops who request specific components. However, he has a package of engine parts and procedures that he knows will satisfy the customer.

“We have done so many of these over the years that we have learned all the snags that could happen, and take the necessary precautions to ensure they don’t,” Wilson says.

For the complete story, visit www.enginebuildermag.com/engine-of-the-week/

Toyota 1.8L 3TC

What started out as a basic engine refresh gave Lake Station, IN engine builder James Hamilton, Jr. a chance make magic with a 1981 Toyota 1.8L engine.

Initially, the job came in for basic machine work on the block, the crank, a set of rods and cylinder head work. The customer wanted Hamilton Performance Engines to do the necessary degreasing and bore the block, but then asked if Hamilton would consider putting the engine together.

“It ended up turning into an assembly,” he says. “Judging by the way the engine looked, it didn’t look like it had a lot of problems, but he wanted to make upgrades.”

Some mild improvements later using modern aftermarket parts and the little Toyota now offers the performance the customer wanted.

“It was a real mild increase and perfectly safe for pump gas,” he says. “We tried to create a little more low-end torque with the engine, which is good for what he’s doing. He isn’t drag racing or going to Bonneville, he just wanted something that will run well.”

For the complete story, visit www.enginebuildermag.com/engine-of-the-week/