Unless you’ve been living under a rock for the past 40 years, it’s pretty likely you’ve come across the Katech Engines name and know of the shop’s extensive work. Katech, which is located just outside Detroit in Clinton Township, MI, is a performance engine and vehicle builder that serves the aftermarket, motorsports and corporate markets.

Katech Engines has helped its customers win races at some of the most demanding venues worldwide such as Indy, Le Mans, Daytona, Sebring, Dakar, and many more. Aside from developing 1,000+hp engines and complete vehicles, Katech also manufactures its own branded components such as ported throttle bodies, cylinder heads and blowers, and it all happens inside its 36,000 square-foot facility.

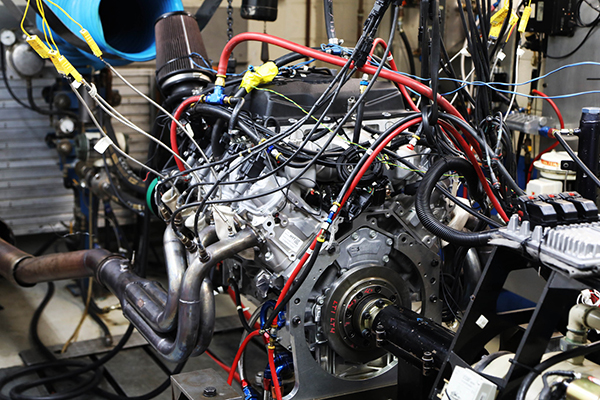

Katech is home to an expansive lab and machine shop, a fully equipped car shop, three engine dynamometer labs, three engine performance labs, and a fully equipped CNC lab. With all of these capabilities it’s no surprise that the shop has been involved in a number of industry firsts, and we recently caught up with Jason Harding, Katech’s director of aftermarket operations, to discuss Katech’s latest development of an LT5 engine.

To start, Katech got ahold of GM’s LT5 engine looking to further develop the power plant for marine applications. However, the lessons the shop learned in the development process of the LT5 apply to automotive applications as well.

To test the different variations of the LT5 engine that Katech came up with, they ran the engine on their Schenck dyno between 2,800 rpm and 6,600 rpm, recording peak numbers.

“First, we base lined the factory engine with our XDI fuel system on it,” Harding says. “The stock engine with a fuel system on pump gas, made 840 peak hp and peak torque of 796 lb.-ft.”

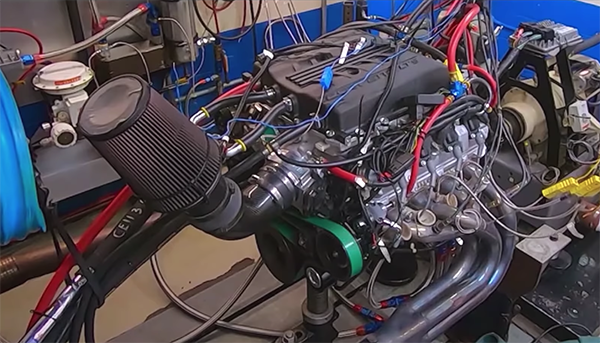

From there, Harding says the team started playing around with the factory supercharger, added bigger injectors and used E85.

“With that set up the LT5 made 925 peak hp and 859 lb.-ft. of torque,” Harding says.

Next, the shop added a smaller upper pulley, which took the peak hp to 992 and 991 lb.-ft. of torque. Then, the shop ported a Katech supercharger and added a Katech 103mm throttle body that allowed the LT5 to produce 1,013 peak hp and 1,011 lb.-ft. of torque. But Katech wasn’t done yet. The shop saw there was still plenty of potential.

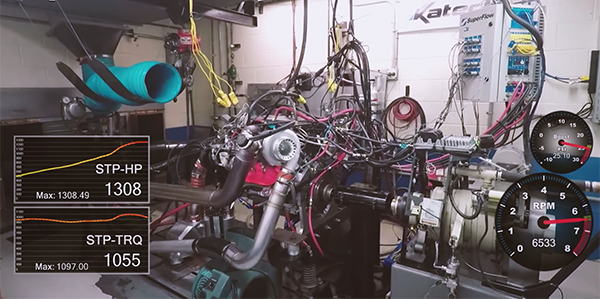

“From there, we decided to port the heads and installed a Hellion Gen 6 Camaro twin-turbo kit that uses Precision turbos,” Harding says. “We also put a Procharger intake manifold on it because we needed an intake that could bolt to the cylinder heads to replace the supercharger. We hit 1,308 hp and 1,097 lb.-ft. of torque! To our knowledge, that’s the highest horsepower Gen 5 engine on E85 anybody’s ever done.”

According to Harding, because their dyno is only rated to 1,000 hp and the LT5 was pushing its limits, the boost was regulated through torque peak to save the dyno.

“That was regulated down,” he says. “It doesn’t make its max boost until higher in the rpm after torque peak. It’s the torque that the dyno struggles with, especially at lower rpm. We were regulating the boost to keep that number low until we got to a higher rpm where the dyno could handle it.”

On the LT5’s 1,308 hp run, Katech used 25 lbs. of boost. Other than the changes mentioned, Katech didn’t use any other aftermarket parts on the build. The shop also didn’t use any port fuel, auxiliary fuel or methanol. All fuel was going through the DI injectors and Katech’s Xtreme DI fuel system.

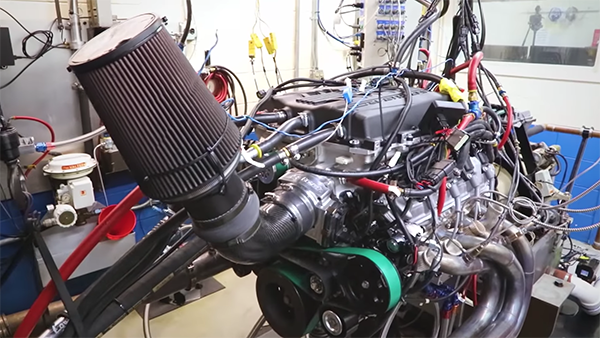

“It took a long time to tune and get dialed in, and we ramped up the boost very slowly as we were doing calibration,” Harding says. “These changes really pushed this Gen 5 application and we needed to slowly ramp up and make sure we did it step by step.”

These modifications to the LT5 have been something Katech wanted to do for a while. It was just a matter of resources and timing. The engine’s E99 computer also made the modifications more difficult.

“The computer that runs the LT5 – the E99 – has no support from HP Tuners because they haven’t cracked it yet,” Harding says. “You’re not able to run the engine on that computer, so there was no way to control it. GM released the crate engine LT5 with an unlocked computer, but still HP Tuners doesn’t support it yet. So there is no way to tune that E99 computer. We ended up with a workaround to make this work for marine applications, which once we figured that out, it became reality for marine applications or swap applications.”

Katech took the LT5 one step further late in their development of the engine by using C16 fuel and got the engine to produce 1,486 hp and 1,283 lb.-ft. of torque.

The Katech LT5 engine would be a good fit for power boats, air boats, hot rods and street/strip vehicles. As of now, Katech is still flushing out how their LT5 engine is going to fall into a package for customers, but if somebody had a boat they wanted to put it in, Harding says they could start talking to them right away.

The Engine of the Week eNewsletter is sponsored by PennGrade Motor Oil and Elring – Das Original.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s managing editor, Greg Jones at [email protected].