When we spoke with Darrell Makins, shop manager of Noonan Race Engineering in Spartanburg, SC, the shop was as busy as ever with 60 billet blocks in queue for production. Noonan starts each build from an 815 lb. raw chunk of aluminum. With 60 engines on deck, that makes for a total of 48,900 lbs. of raw aluminum forgings. After getting machined, each block comes out weighing around 127 lbs., which makes for roughly 41,000 lbs. of aluminum waste and 7,620 lbs. of finished aluminum blocks.

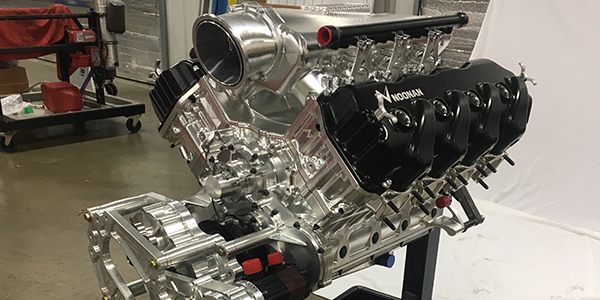

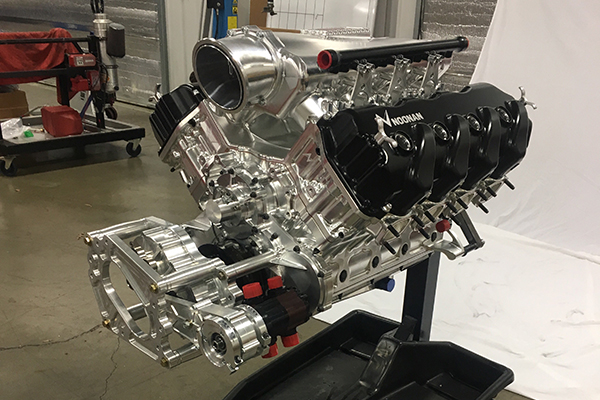

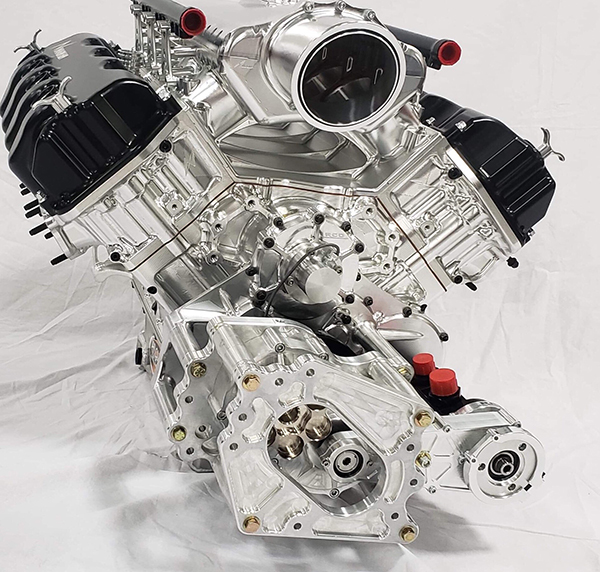

One of those hunks of aluminum were turned into a 4.9˝ Billet Hemi Big Dawg engine and we got all the details of the build.

Noonan Race Engineering was founded by Jamie and Renee Noonan in 2006. Jamie is a renowned Australian V8 supercar engine builder from Australia. Noonan has built a worldwide reputation as a high-end provider of billet aluminum, high performance, hardcore engine componentry for professional motorsport teams and enthusiasts who want the ultimate in performance. The shop specializes in manufacturing its own billet cylinder heads, billet manifolds, billet valve covers, and billet engine block designs for both supercharged and turbocharged Alcohol Hemi and LS engines.

Noonan Race Engineering is constantly relying on its experience and the interactions of its customers to continuously design, test, develop and build better performance solutions to stay ahead of the demanding curve associated with racing.

In June 2017, Noonan Race Engineering relocated its headquarters to the United States with the purchase of a 22,000 square-foot facility in Spartanburg, SC. That’s when Darrell Makins, a life-long resident of Spartanburg and an engine builder himself, joined the staff. Noonans has seven full-time employees.

“I met Jamie and Renee six years ago,” Makins says. “We were customers of theirs. I ran the NAS race team in PDRA. When Jamie and Renee quit racing, they acquired this property to move Noonan Engineering to the U.S. I helped them get affiliated with this area and I ended up becoming the manager here and I never left.”

Noonan Race Engineering’s core business is drag racing billet components – blocks, cylinder heads, manifolds, valve covers, main caps, and gear drive covers. The shop makes all of its components under one roof.

“Our main focus at the moment is drag racing – Top Alcohol, Funny Car, Top Dragster and Pro Mod,” Makins says. “We also make some one-off parts as well. We can manufacture anything out of aluminum in the automotive world.”

One of Noonan’s newer engine designs is its 4.9˝ Billet Hemi Engine called the Big Dawg. This engine is currently the shop’s star engine platform.

“It’s an engine Jamie started work on four to five years ago,” he says. “The very first one ran two and a half years ago. The Big Dawg is our tall deck version and we also have a standard deck version. Our Big Dawg platform is brand new – some of our very first engines just went out the door.”

The block starts out as a rectangular forged block of 6061 that weighs about 800 lbs. After 46 hours of machining time, it’s down around 125 lbs. complete. Most of the mass is in the waste basket. The block, as well as the cylinder heads, are fully machined in-house. The cylinder heads are made of 6061 T6 billet material.

“The block, heads, manifold and the valve covers are all manufactured out of billet here in the shop,” Makins says.

The rest of the internals for the 4.9˝ Hemi Big Dawg engine come from various aftermarket suppliers. For crankshafts, Noonan exclusively uses Winberg, but will soon be adding a few others such as Sonny Bryant and Callies as options. The rocker arm system is from either Reid Rocker Arms or Manton. The gear drive components are provided by RCD Engineering, while the front cover is machined in-house. The billet connecting rods come from either MGP or GRP and the pistons are from either CP or Diamond.

“Our choice for components sometimes depends on the application and sometimes it comes down to timing and delivery,” he says. “If one company is extremely busy, we will possibly use the other.”

For valves, Noonan uses Manley. The oil pump is from Barnes Systems. Piston rings are from Total Seal. The bearings are Clevite. The camshaft is from Bullet Cams and the engine gets finished with a Dan Olson oil pan.

“The big difference between the Big Dawg and our standard 4.9˝ is the standard version has a deck height of 10.225˝ and our Big Dawg, which allows more stroke, has an 11˝ deck height,” Makins says. “We also always sleeve these engines, for which we use Power Bore nodular iron sleeves.”

According to Makins, the normal lead time on one of these engines, for a completely custom platform, is about six weeks.

“We have built one of these engines in as quick as two weeks,” he says. “The cost for a standard Roots motor that you’d find in an NHRA Pro Mod car would be around $74,000. That’s ready to put your supercharger and fuel system on and go. There are some extra things you can add. We do have a higher end oiling system company, Auto Verdi, out of Sweden. They have an upgrade to the oiling system and there are some upgrades you can make to the engine that could add anywhere from $4,000 to $5,000 to that price.”

For that amount of money, customers are expecting top-level performance, and Noonan Race Engineering delivers. The fastest the Big Dawg engine has gone in an Outlaw trim Screw blower is 5.42 in the quarter mile. The fastest NHRA legal is 5.67 in the quarter mile.

These engines run somewhere between 12.5:1 and 13:1 compression and can come in different configurations. Noonan Race Engineering has run the 4.9˝ Hemi Big Dawg with a Roots supercharger, a Screw supercharger, a centrifugal supercharger, a turbo, and a Procharger.

“The 4.9˝ Hemi Big Dawg is for a door slammer platform like Pro Mod, Outlaw Pro Mod or Radial racing platforms,” Makins says. “We also have a few tractor pulling customers starting to buy these.”

We have little doubt that those customers will be very happy on race day!

The Engine of the Week eNewsletter is sponsored by PennGrade Motor Oil and Elring – Das Original.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s managing editor, Greg Jones at [email protected].