As one of the leading machine shops when it comes to high-performance engine work and billet componentry, we caught up with Barry Pettit of Noonan Race Engineering during the 2021 PRI show to talk about the shop’s latest billet goodies for the LS and LT market and why more racers are choosing to use billet over cast options.

“Our work on the LS platform started with customer request,” Barry Pettit told us. “A lot guys call in and say they want a billet block. They want a tall deck wet block to go do Drag Week with. The customer requests have driven us to come up with Noonan LS packages. We have a 454 and a 427 that are pretty standard.”

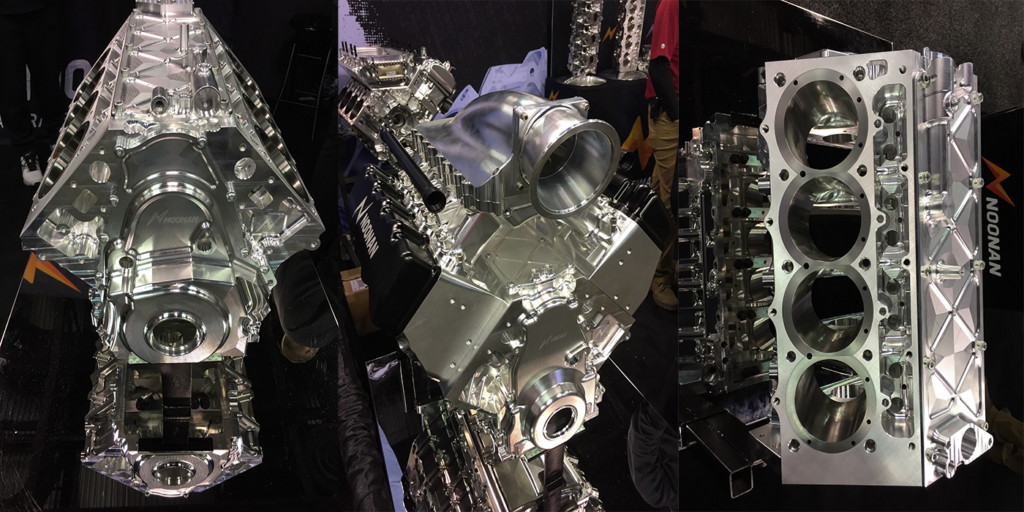

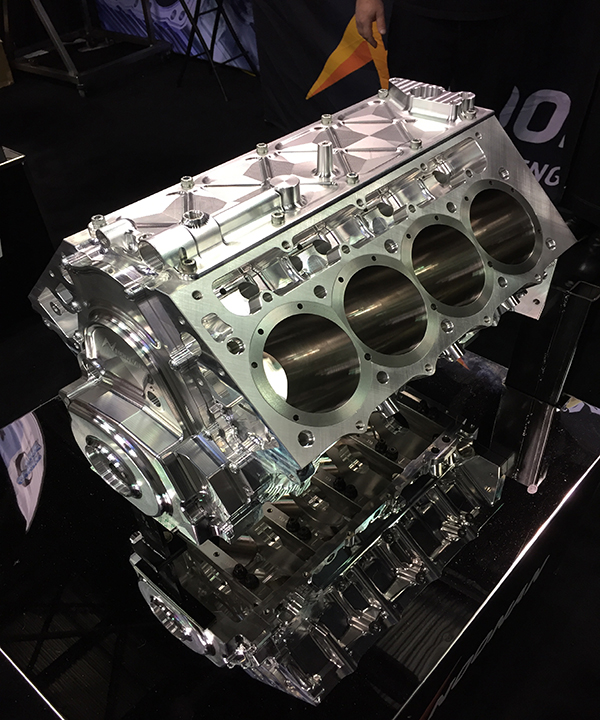

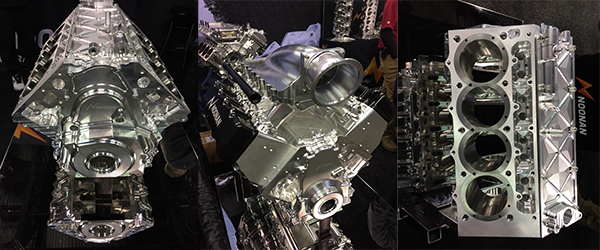

Noonan Race Engineering, which is located in Spartanburg, SC, offers customers billet LS blocks in two different deck heights – 9.240˝ and 9.750˝. For each of those deck heights, you can go into an almost infinite amount of combinations.

“We manufacture all of our own main caps, for example,” Pettit says. “For all of our LS platforms, you can do either a steel main cap or an aluminum main cap. For each one of those, you could do either an LS-style main bearing or a Cleveland-style main bearing. A lot of guys will run the Cleveland for the big power stuff. Our LS blocks also feature a raised cam, which helps get the valvetrain a little straighter. It’s not a traditional LS height, but there’s a few things in there that we’ve tweaked, which customers seem to really enjoy.

“It’ll turn into essentially a limitless amount of options that a customer could want. It’s the reason that the billet engine makes a lot of sense for an LS customer. Everybody has a secret combination that they want. They can come to us and we can punch it out in whatever option they want and give them a solution that fits.”

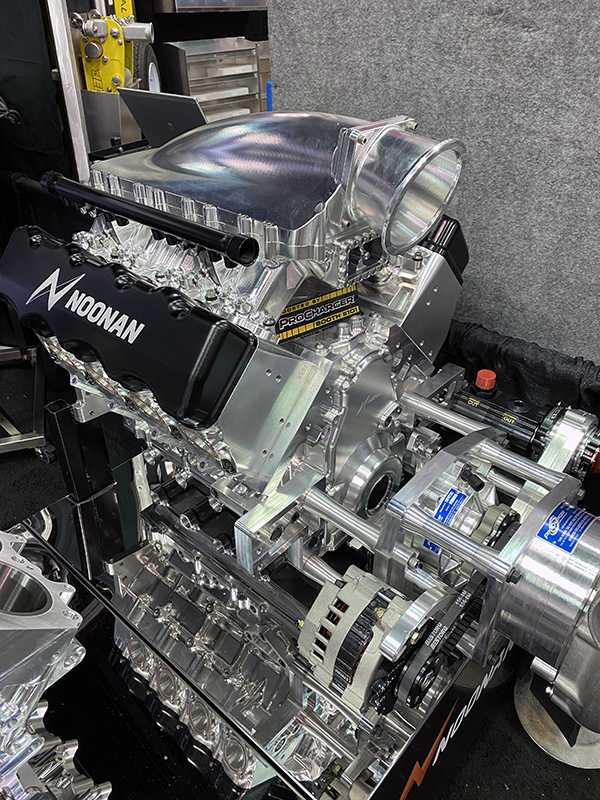

In addition to offering billet LS blocks, Noonan also launched a billet LT block at the beginning of 2020, which is another growing segment of high performance.

“The LT block is a really good platform,” Pettit says. “We’ve got guys doing 2,200 horsepower on those. We’ve been real tight with Late Model Engines and those guys do a lot of testing and work with us on the LT block. They’ve been a really good customer of ours and they’ve done a fair amount of these engines now, and we’ve had really good luck with them.

“Our LT block is a water configuration, so it has water going through around the cylinders. It’s a really good alternative for somebody to do a Drag Week car or a 1,500-2,500 horsepower street car if they want. It’ll come standard with six-bolt steel main caps. It’s a pretty stout unit.”

According to Pettit, the differences between Noonan’s LS and LT blocks are very minimal. In fact, he mentioned that you could put an LS head on the LT block.

“As far as the configuration and the architecture for us, they’re very similar,” he says. “If a customer really wants an LT configuration, the biggest differences are the front geometry and the front bolt pattern and stuff like that.”

Not only does Noonan offer billet block combinations, but it also specializes in billet manifolds and cylinder heads as well.

“With the cylinder heads we offer, we can do either a solid cylinder head, a dry deck, or a full wet pass through cylinder head,” Pettit explains. “Again, it turns into limitless options, but we normally run those with a Manton rocker setup and a few different valve sizes we can run depending on what the customer is trying to do.

“One of the coolest things is the manifold. We have an LS long runner turbo manifold. We really go after the best flow that we can for a turbo or ProCharger application and focus the air where we want it to go. We can put ribs inside the lid to drive air the way that we want it and really make it exactly how it needs to be. We also have screw manifolds and such that we could do as well.”

You might be wondering what some of the inherent benefits are of running a billet engine combination? Well, for starters, it looks absolutely gorgeous, and it should for the added price point. But, billet also has some serious upside over cast options.

“The benefits of a billet block are that we can put material where it needs to be without adding weight,” he says. “We can go through and look at the pan rails, for example. We can make our pan rails extremely thick to give the support there that we need, but then you can build up architecture around that to give the main saddles the support that they need to function correctly under a high rpm condition.

“With a cast block, you can do that, but if you ever need to make a change it’s a whole process. With billet, we can do a quick program change and have a continuing product moving forward. We’re not tied to a certain casting. Billet helps us to be able to move material around, but also gives us a higher degree of accuracy. I have a very high confidence that when our blocks come out of the machine they’re exactly what they were supposed to be. Every hole is exactly where it needs to be every single time. Whereas, with any kind of casting, you’re going to have a variance.”

Pettit, who is a racer himself, also points out what might be the biggest benefit of them all – billet components are much more easily repaired.

“One of the biggest benefits of billet, for me, is the repairability of a billet engine,” he says. “In drag racing, your tuner is going to get it wrong someday, it’s going to happen. If you poke a hole inside the block, nine times out of 10, we can repair it. We can weld the material back up, re-machine it and you can’t even tell there was a problem.

“It’s the same for cylinder heads if you blow a head gasket. We’ve had heads come through where it is completely flame crossed from the cylinder all the way out the side of the head. The billet allows us to repair it so it goes back to the customer like a brand new head. Using billet allows us to provide a lightweight solution that’s repairable, and it really performs at the optimum level for our customers – that’s really what it boils down to.”

Something else to keep in mind in today’s current environment and supply chain uncertainties is that using billet gives you additional flexibility.

“Another benefit in today’s world with the supply chain issues, is if we ever have a problem getting certain parts, we can machine it to fit and meet our standards,” he says. “There’s opportunities there that make it beneficial for us. We can take any hunk of billet from A to Z in-house and machine everything to someone’s exact specifications.”

There you have it. With a billet engine, you might cry once when you buy it, but you won’t be crying two or three times whenever you have a problem. Oh, did we mention billet engines can handle crazy amounts of horsepower? You won’t be crying in the winner’s circle – unless those are tears of joy. Consider billet components for your next LS or LT build. EB