As FCA (Fiat Chrysler Automobiles) recently celebrated “Hemi Day” on April 26, or 4/26, to honor the 426 cid Elephant Motor, we are reminded of the nearly 70 years of this iconic engine design that all started in 1950.

The original hemispherical combustion chamber engine design was introduced with the FirePower name for 1951 model-year Chrysler and was rated at 180 hp. The history of the Hemi is filled with plenty of memorable highlights such as Richard Petty’s dominance at the 1964 Daytona 500 where he lapped the field. Or “Big Daddy” Don Garlits breaking the 200-mph barrier with his 426 race Hemi.

With a rating of 345 horsepower, the Gen III 5.7L Hemi made its debut in 2003 in the Dodge Ram pickup. The third-generation engine is available in four cubic-inch displacements: 345, 370, 376, 392, but they’re more commonly referred to by their metric equivalent: 5.7L, 6.1L, 6.2L, 6.4L. The Gen III Hemi has even been on the “Ward’s 10 Best Engines” list six times from 2003 through 2007, and again in 2009.

The Hemi engine in the 2018 Dodge Challenger SRT Demon is derived from the “Hellcat” and produces 840 horsepower in stock trim from its supercharged 6.2L and runs on 100-octane race fuel. It produces 808 horsepower on 91-octane pump gas.

These are just a few of the highpoints of the Gen III Hemi, which ironically is not a completely hemispherical design anymore. With small “squish shelves” on both sides of the chamber, the center was hemispherical to incorporate big valves and ports that outflow LS1 heads by 24%. It also uses a coil-on-plug ignition system with not one, but two spark plugs per cylinder to shorten flame travel, leading to more consistent combustion and reduced emissions.

Chrysler added a Multi-Displacement System (MDS) in the original Hemi design to shut off two cylinders on each bank under light load to improve fuel economy. The main oil galleries supply oil directly to the solenoids that disable the lifters, and the oil for the lifters came down through the pushrods from the rockers up topside.

While the MDS system runs trouble-free in these engines, the first block wasn’t designed to include the variable valve timing (VVT) system. Chrysler had to redesign the Gen III block to incorporate its next evolution VVT in 2009. This redesigned Hemi can cruise in four-cylinder mode about 40 percent of the time, which is twice as much as the previous-generation MDS cylinder-deactivation system.

The rocker assemblies are about the only two things that carried over from the original Gen III design. While Chrysler made significant changes to the block and heads, there are some evolutionary upgrades also, including bigger valves and ports, updated cams and lifters along with a stronger crank and rods and a high-volume oil pump. With that in mind, let’s go through some of the differences between the 5.7-liter layouts.

Cylinder Heads

The second generation VVT engines came with a new head that included several changes. It looks like the “squish shelves” on both sides of the Hemi chamber didn’t provide enough quench and squish. We believe the reason Chrysler had to change over to an oval chamber was to meet emissions.

There are two different casting numbers for the “Eagle” head as it’s known, but both heads are identical with an EGR pad on one end. The only reason there are two different casting numbers is to allow them to differentiate the right from the left on the assembly line when they drill the right head for EGR (you can’t make this stuff up!). Here are the new changes on the heads:

- The connecting rods were beefed up because the VVT engines make more horsepower. There are tabs that stick out on both sides of the balance weight that identify these rods.

- They have a 65cc oval, closed chamber instead of the 85cc hemispherical chamber that was used for the early heads. The compression ratio was increased from 9.6:1 to 10.5:1 to improve the combustion process, and therefore, fuel efficiency.

- The intake valves are slightly bigger at 2.05˝ instead of 2.00˝, but the exhaust valves are still 1.55˝ like the early ones. Both valve stems are longer because the rocker pedestals were moved up higher on the head to make room for the new exhaust ports.

- The new, square intake ports flow 323 CFM at 0.500˝ of lift. That’s about 14% more than the ones on the original Gen III heads and they actually flow better than the ones that were used on the 6.1L motors for the SRT, but the SRT heads are still better overall.

- The “Dee-shaped” exhaust ports on these heads flow about the same as the square ones on earlier heads, but they’re shaped like the ones on the 6.1L SRT heads now.

- The casting number left bank head is 53021616DE and the right one is 53021616DD casting. They both have a pad for the EGR valve on one end, but that only matters if it’s for the early Aspen or Durango because they’re the only ones that need the two bolt holes and the exhaust passage drilled for EGR on the right head. Otherwise, the heads are interchangeable.

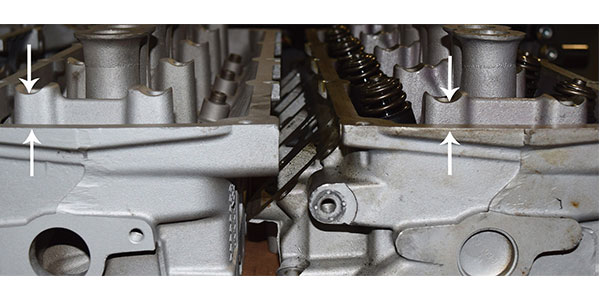

Valvetrain

All of the VVT cams have more lift, so both the standard and “de-ac” lifters were modified to accommodate the difference. The VVT lifters can be used in the early motors that had the lower lift cams, but the early lifters won’t work in the VVT motors because they can’t accommodate the high lift cams when they are collapsed in the MDS mode. The VVT lifters are easy to identify because the flats on both sides are wider and the top is chamfered to make it easier to install them in the plastic yokes.

The pedestals for the rocker shafts were raised up by nearly 0.200˝ because the top of the head casting was moved up to make room for the new “Dee-shaped” exhaust ports, so the pushrods are all about 0.150˝ longer. That means the valves are longer, too.

Cylinder Block

Adding VVT to the Hemi engine required a new block with had three additional oil passages and an extended front cam bearing that allowed them to supply oil to the cam phaser through the front journal. The front of the block above the mains was moved out by about 0.600˝ so it ended up flush with the side rails on the timing cover. This change allowed them to add an oil passage that connected the main oil gallery to the oil control valve that directed oil to the phaser through the front cam journal. The cam bore for the front journal was increased by about 0.180˝, and it was about 0.550˝ longer, too.

There were two other small changes made to the block – the hole for the temp sender on the left side of the timing cover was removed and one more bolt boss was added on the driver’s side, close to the front and about midway up on the block. The new block was a 53021319DK casting. The last three digits of the part number and suffix are stamped in the back of the rear cam journal.

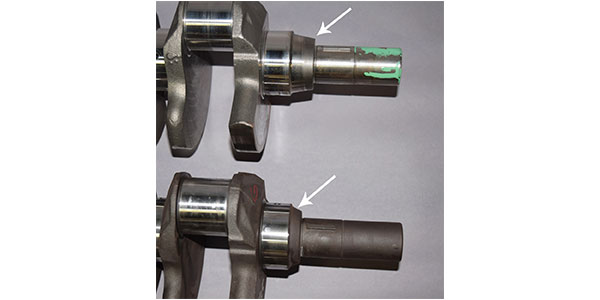

Rotating Assembly

The VVT motors came with a new crank that’s a 53021300BB casting. It’s still made of cast nodular iron, but it’s considerably stronger than the original design, according to Chrysler. The most noticeable difference is the length of the tapered area in front of the main journal that creates the step that locates the crank gear on the snout. It was extended by about 0.460˝ so the crank gear would line up with the cam gear that was moved forward when the block was modified for VVT.

The powdered metal, forged rods were supposedly redesigned stronger, but they look just like the early ones except for a slight difference in the balance pad on the big end. However, we tend to believe that they’re stronger because the VVT motors make more horsepower and torque and the original rods were the weak link in the Gen III motors, so they were due for an upgrade. We wouldn’t recommend using the early rods in the late engines.

All of the VVT motors were supposed to have had bushed rods according to an early press release and it appears that a few of the early 2009 Durangos actually came with bushed rods, but all of the engines built since then have had press fit pins.

The oil control valve provides pressurized oil to the phaser thru these five passages that are aligned with the corresponding holes in the cam.

The first Gen III piston was modified to accommodate a new, narrow ring pack that had 1.20/1.20/2.0mm rings instead of the 1.50/1.50/3.0mm rings that were used up through 2008. Other than that, it appears to be the same piston that even has the same identification numbers on the inside of the skirts.

Camshaft, Bearings and Phaser

The camshaft gets confusing because five applications share VIN code “T,” which are all different. Chrysler used five different cams that are NOT interchangeable. The MDS cams are unique because four of the intake lobes have a “primary ramp” that takes up the “locking lash” in the MDS lifter before the “secondary ramp” closes the check ball inside the lifter. Also, note that the timing on the four MDS exhaust lobes is advanced by a few degrees.

The new oil pump housing is thicker and has a bigger pickup tube because the output was increased by 22% so it could be used to supply oil for the VVT system. It also sits up higher than the old one because the crank gear was moved out further on the snout.

The bottom line is that each cam is unique to a particular application, and they are not interchangeable. Engine Builder contributor Doug Anderson, bought four of the five cams (except the one used in the hybrids) to identify them by vehicle application. The part number is etched on the back of the rear journal and the ID grooves are machined in the barrel that’s in front of the back journal.

Chrysler initially said that the VVT cams would be made of “high strength billet steel,” but Anderson’s samples were all cast iron, so he concluded they made a running change. Here’s the list of the cams:

- The Challenger with a manual transmission uses a p/n 53022064BD that has one groove machined in the barrel, tight against the rear journal, along with 064BD on the back side of it. It’s a performance grind that has VVT, but it doesn’t have MDS because that requires a torque converter that can be momentarily unlocked to absorb the torque spike that occurs when the four disabled cylinders are reactivated.

- The 2500 and 3500 trucks use p/n 53022314AD that has one groove machined in the middle of the barrel that’s in front of the rear journal and 314AD stamped on the back of it. It’s a truck cam that has VVT, but it doesn’t have MDS because the ¾ ton and 1-ton trucks aren’t required to meet the federal CAFE fuel economy standards like the ½ ton trucks, so fuel economy isn’t an issue.

- All of the 1500 pickups came with a p/n 53022263AF cam that has 263AF on the back of the journal, but there isn’t a groove in the barrel. This cam was also used for the’ 09-’10 Aspen and Durango, except for the hybrids. It includes VVT, MDS, and SRV (the short runner valve) for the active intake, so it has a very sophisticated profile.

- The fourth cam fits all the cars and Jeeps with automatic transmissions along with the new Durango that was based on the Grand Cherokee platform starting in 2011. It’s a p/n 53022372AA that has one groove machined all the way forward on the barrel in front of the journal and 372AA stamped on the back of the journal. This one has VVT and MDS.

- The last one is for the Aspen and Durango hybrids that were built in limited numbers in 2009. It’s supposed to be a p/n 53022065BE, but it came up as a discontinued number when we ordered it, so all we know is that it probably has 065BE stamped on the back of the rear journal.

According to Anderson, the hybrid engines came with “a modified version of the cam for a passive intake with MDS,” but he says it’s not the same as any of the other cams.

These engines require a unique bearing set with a wide front bearing that has two slots that are located directly over the grooves in the cam journal and the number three bearing is Babbitt coated to “reduce friction at a critical point on the cam, which improves durability during cold operation.” Dura-Bond offers a bearing set for these engines.

All of the Hemi motors built since 2009 have a cam phaser that provides variable valve timing “for improved breathing and better volumetric efficiency under a wide variety of conditions.” Using VVT, Chrysler could advance the cam to increase torque under light loads so the engine could run on four cylinders at 70 mph and stay in MDS up to 40% of the time. It also allowed Chrysler to eliminate the EGR valve on everything but the ‘09-’10 Aspen and Durango that were built on an existing platform with a PCM that apparently couldn’t accommodate the use of VVT for EGR.

All of the rest of the VVT applications create EGR by retarding the cam to leave some residual exhaust gas in the cylinders. Just for the record, Chrysler built less than 10,000 of the ‘09-’10 Aspen and Durango sport utilities with the VVT engines. Both of them were discontinued on December 19, 2009 and they’re the only ones that had an EGR valve during that time. It’s likely this was an electronics issue and not a mechanical problem.

Oil Pump

The oil pump is still a gerotor design that’s bolted directly to the bulkhead on the front of the block. The original part number 53021622BE was superseded by a BF that was replaced by a BG that was superseded by the current number, which is a 53021622BH. They’re all similar (although there were some internal changes made to the BG and BH), but they’re all high-volume pumps that displace 22% more oil than the original Gen III pumps and they’re all interchangeable.

The late high-volume pump will physically bolt on the early engines, but it was moved out about 0.500˝ when the front of the block was modified, so the splines on the early crank gear will barely touch the flats in the new pump. This is why you can’t use the latest high-volume pump on the original Gen III engines.

Crank Sensor Wheel

The original Gen III came with NGC, so it had the 32-tooth crank sensor wheel. But Chrysler went to a 58-tooth sensor wheel on the new Hemi because the computer “needed more immediate and accurate information on the position of the crankshaft during rotation” so it could control and coordinate MDS and VVT along with direct ignition and all of the other electronics used on these engines.

Keep in mind that MDS deactivates four cylinders in firing order sequence, with the exhaust valve closed, in about 10 milliseconds when the computer commands it to kick on. That’s less time than it takes the cam to make one revolution at anything much above an idle. The VVT motors needed a 58-tooth crank sensor wheel along with a 4X cam sensor and a faster PCM.

The tapered area that locates the gear on the front of the crank was extended by about 0.460˝, so the crank gear would line up with the cam gear that was moved forward due to the change in the block.

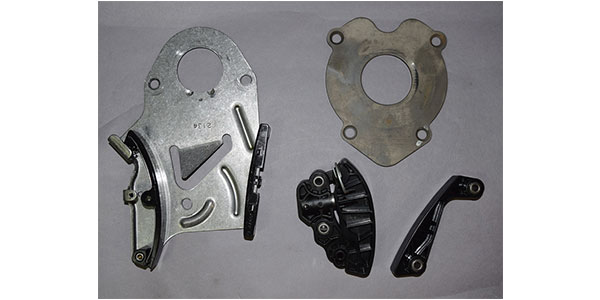

Timing Components

All of the timing components were revised too, including the gears, chain, tensioner and the guide. The cam gear is an integral part of the cam phaser, so it’s not available separately.

The crank gear has 23 teeth instead of the 26 found on the old gear because the pitch on the chain – the distance between the links when measured from center-to-center on the pins – is longer, so the new chain has 76 links instead of the 86 links found on the old one and it’s about 0.100˝ narrower, too.

The colored links on the original chain were replaced by three laser-etched rectangles on the links that are used to time the gears. Additionally, the front cover, which included the cam thrust plate along with a blade-style tensioner and a chain guide, has been replaced by three pieces including a separate cam thrust plate, a plastic chain guide and a tensioner with a spring-loaded piston. The front of the block was moved forward by about 0.600˝ to make room for the wide front cam bearing and the oil passage Chrysler added for VVT.

Active Intake

Although the active intake isn’t included with the long block, you will need to know whether the vehicle has one before selling an engine because it requires a special cam to work with the active intake. You can’t depend on the VIN code to identify which engines have it because Chrysler calls them all VIN “T” even though there are five different ones.

Chrysler installed the “active intake manifold” that varied the length of the intake runner “to expand the engine’s torque and horsepower range” on some, but not all applications. When it’s activated, the butterflies in the intake runners open up at 4,000 rpm to create an intake path that’s half as long, so the engine makes an additional 25 horsepower without losing any torque and ends up with 390 horsepower. You can actually feel the difference when the short runner valve switches over.

The oil control valve that directs the oil to the phaser through the front cam journal is bolted to a machined pad on the back of the timing cover.

Final Thoughts

While there have been growing rumors of a replacement for the Hemi in the not too distant future as OEMs continue to downsize and add turbocharged direct injection systems, Chrysler has been selling around 400,000 trucks a year for a long time. That means there are a lot of Hemis in service that will need to be rebuilt sooner or later. When Chrysler updated the Hemi in 2009, it showed a pushrod engine could be modernized and perform well in many variations from cars to trucks. With the VVT upgrade making 400 lbs. ft. of torque, and the pickups with the active intake rated at 390 horsepower, these engines deliver decent fuel economy, and they’ve been virtually trouble-free. The trucks have held value and will be more likely to receive a new engine than cars. Just make sure you figure out which one fits the application before you send it out the door.